1.What is low pressure injection molding

The low-pressure injection molding process is a packaging process that uses a very low injection pressure (0.15-4MPa) to inject the hot-melt material into the mold and quickly solidifies it. Temperature, impact resistance, vibration reduction, moisture-proof, waterproof, dust-proof, chemical corrosion resistance and other functions, play a good role in protecting electronic components.

2.Molding process and application

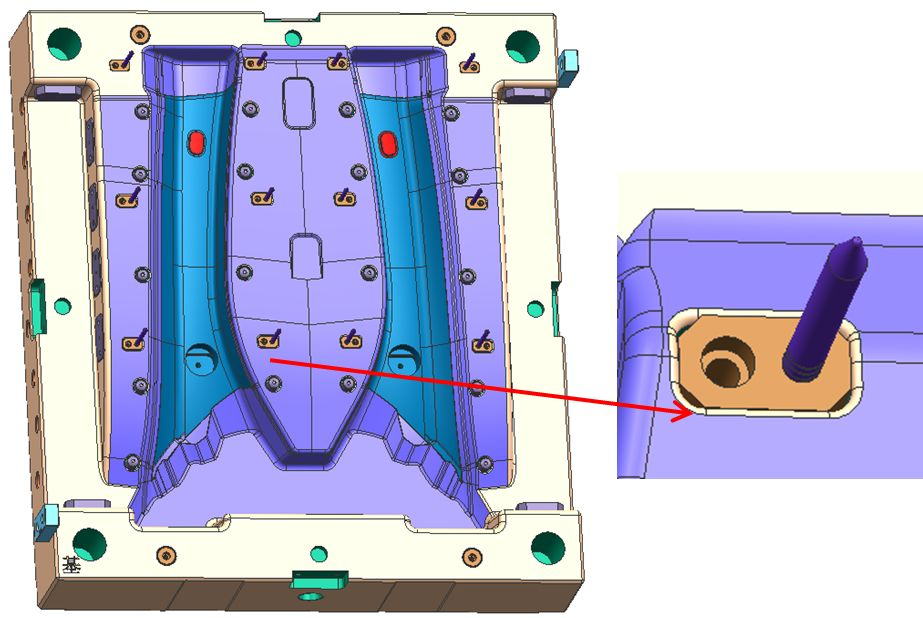

Put the skin into the mold in advance, and then use the thrust of the screw to inject the plasticized molten plastic into the closed mold cavity, and then solidify and shape the product to obtain the product. At present, this process has been widely used in the production of automobile door guards, pillar guards and parcel shelf guards.

3.Advantages

①There is no possibility of falling off

②More environmentally friendly

③Do not require additional secondary coating to improve production efficiency.

④Effectively protect the internal parts of the product and have a low rejection rate.

Good appearance

Post time: Sep-14-2022