25 Years Factory Custom Made Plastics Injection Mould for Car Bumper Parts

With a full scientific excellent management process, great quality and excellent faith, we acquire very good standing and occupied this industry for 25 Years Factory Custom Made Plastics Injection Mould for Car Bumper Parts, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

With a full scientific excellent management process, great quality and excellent faith, we acquire very good standing and occupied this industry for China Molding and Plastic Mold, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

1.Product Introduction

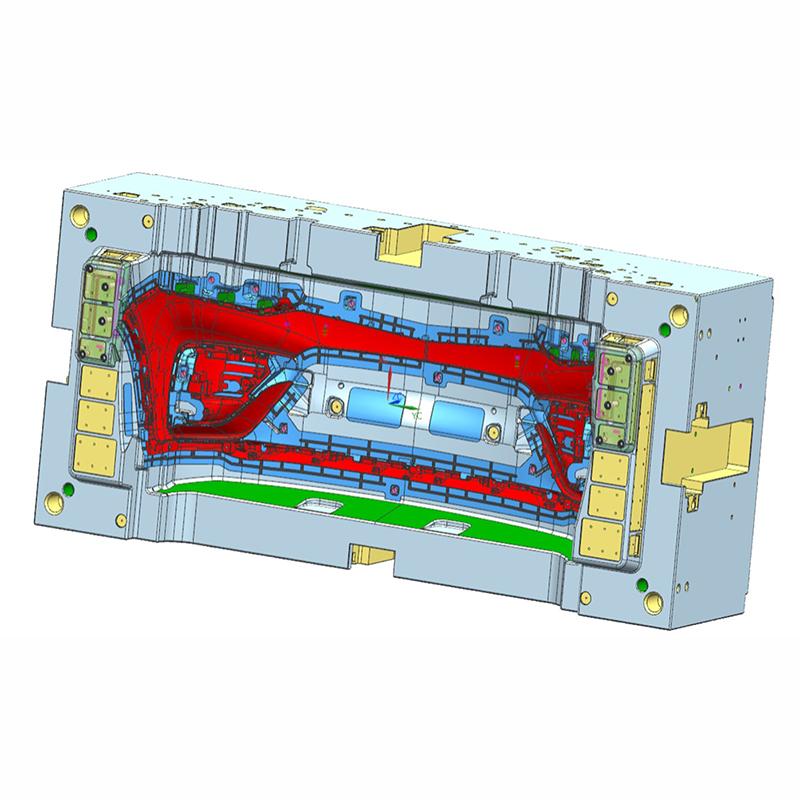

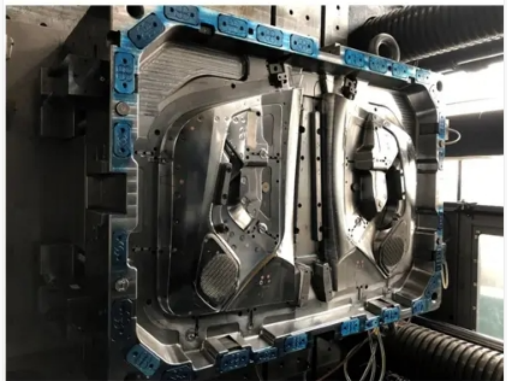

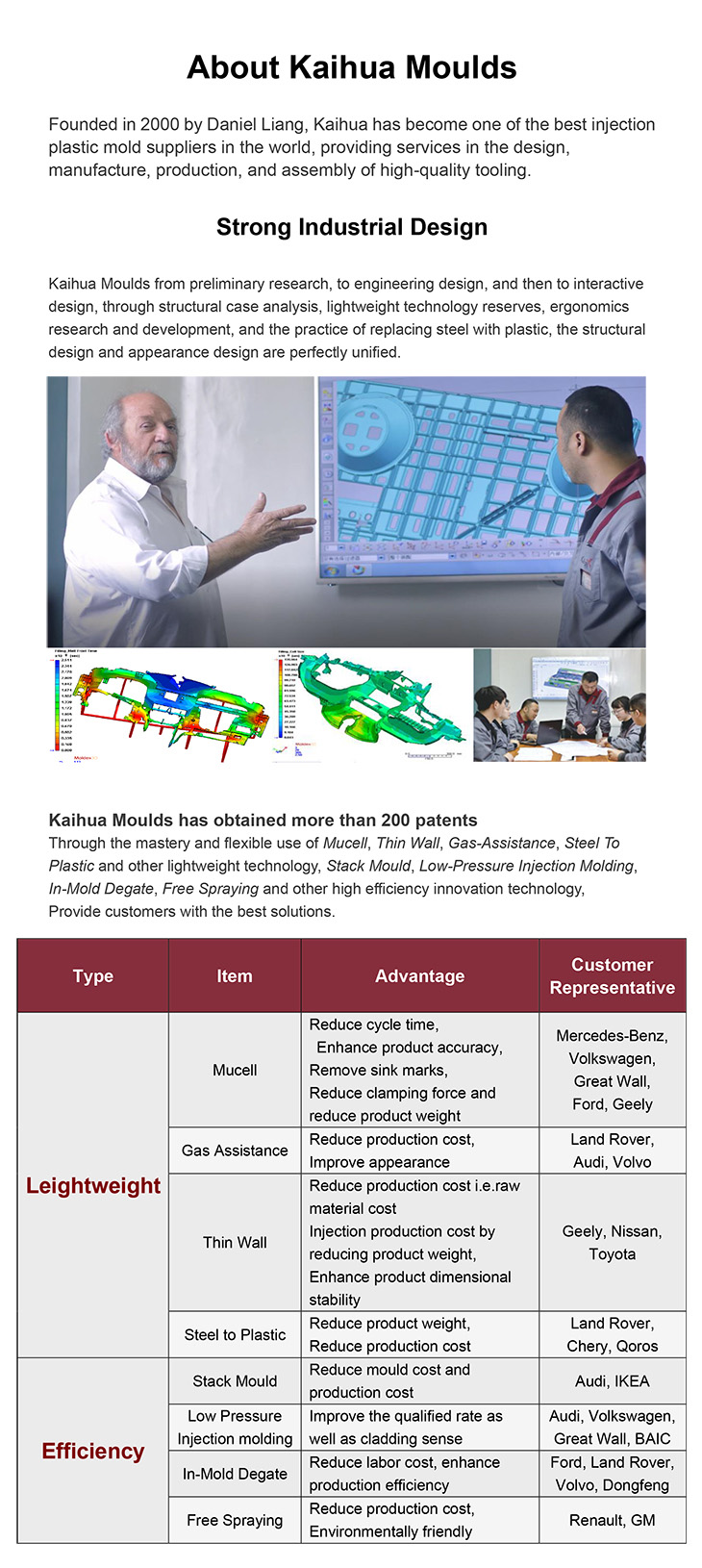

Positioning & Core Services: As a professional provider of automotive plastic injection molding solutions, Kaihua focuses on plastic injection molding for internal parting car bumpers. Core services include product design, mold design & manufacturing, R&D & production, and injection molding for Tier 1 suppliers, with over 20 years of industry experience.

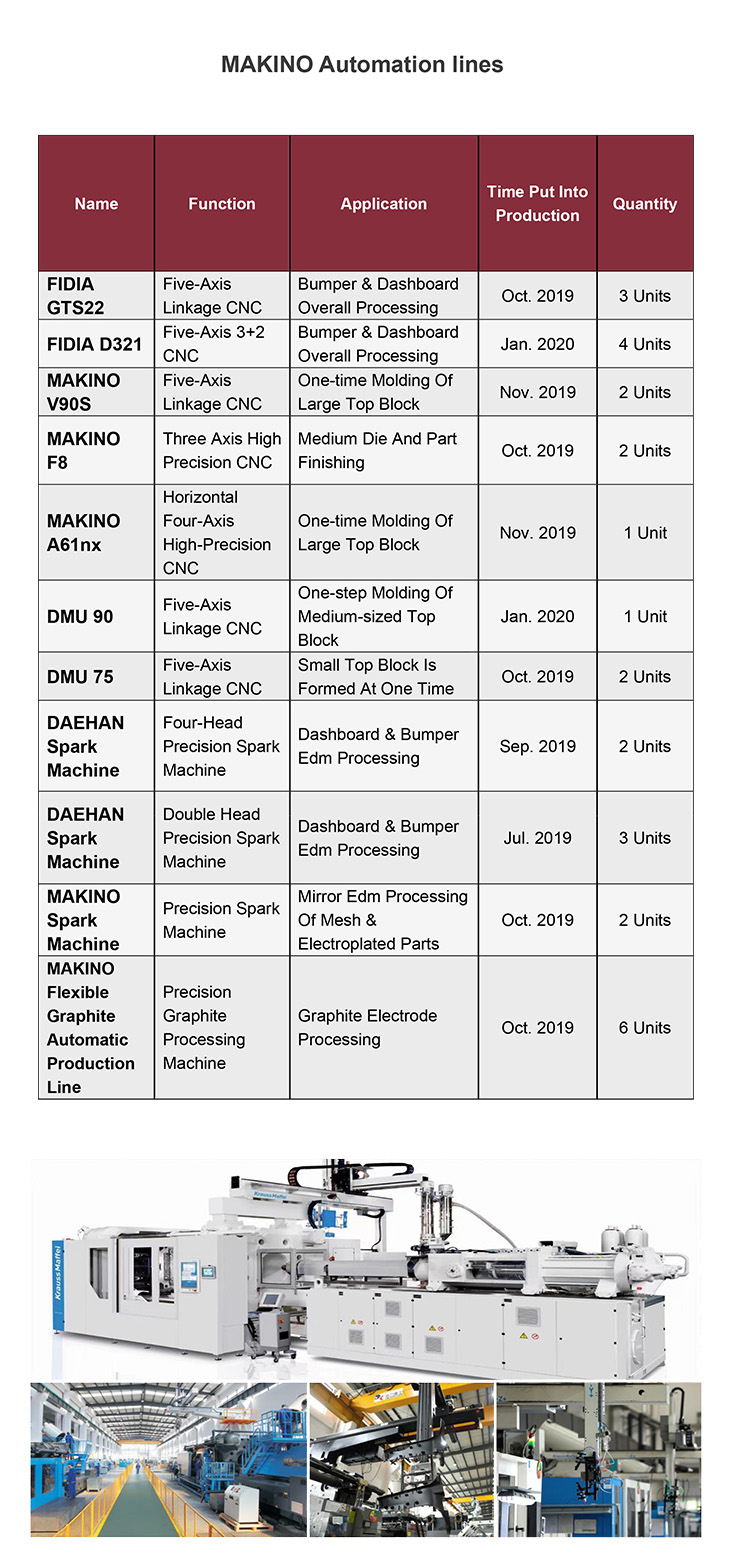

Production & Equipment Support: It has two factories (Huangyan: 45,000㎡, 900+ employees; Sanmen: 36,000㎡, 450+ employees), equipped with MAKINO, FIDIA processing equipment and Kraussmaffei, Haitian injection molding machines to ensure precision and efficiency.

Customers & Service Network: Cooperation customers cover global automakers like GM, VW, Geely and Tier 1 suppliers; overseas offices in Spain, Germany, India, etc. enable quick response.

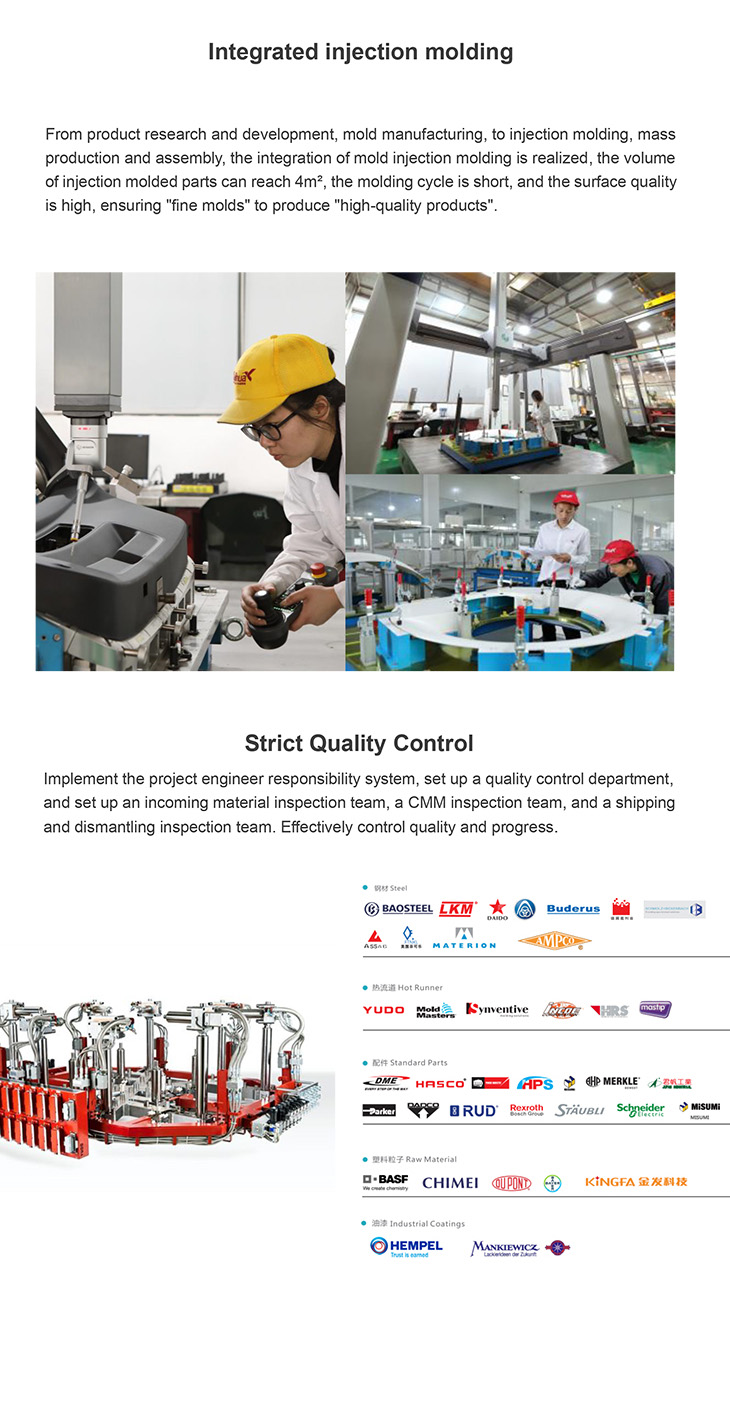

Quality Assurance: Certified with ISO 9001:2015, and adopts digital production management to guarantee stable product quality.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

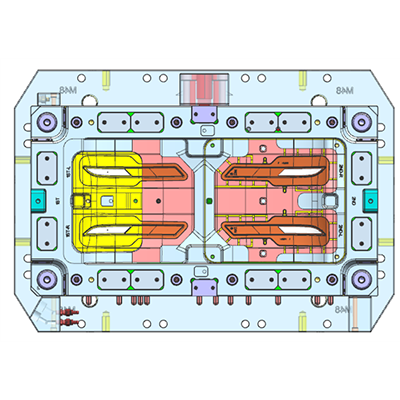

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

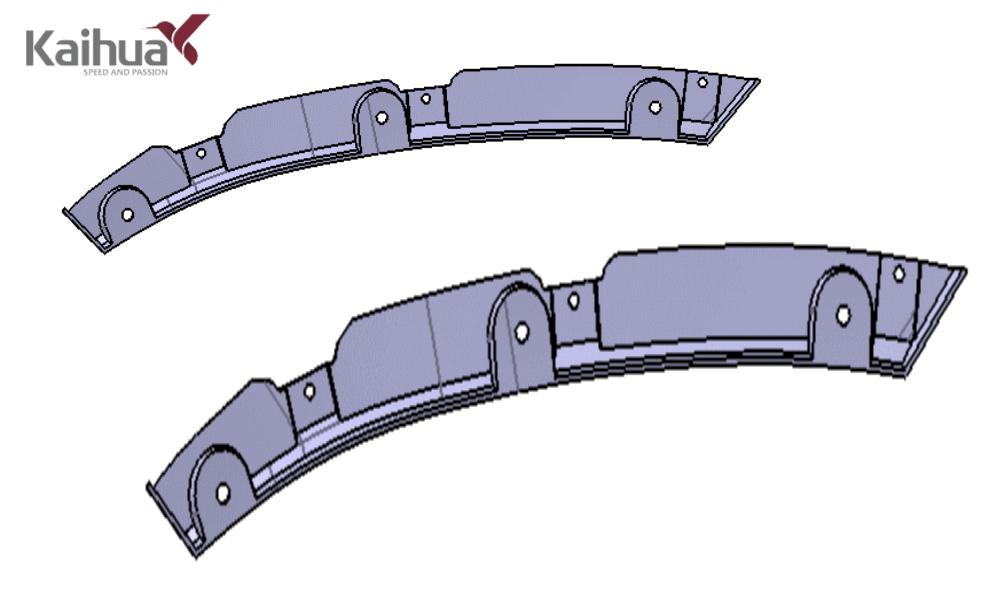

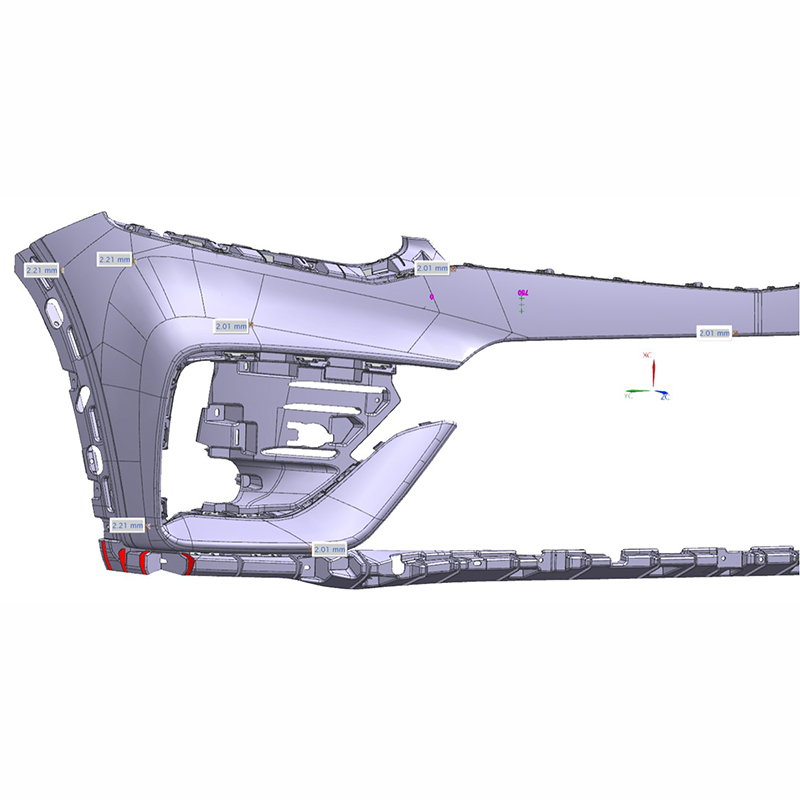

Technical Features : Internal Parting Car Bumper

2.Unequal thin-wall design

The middle area is 2.0mm, and the ends on both sides are thickened gradually to 2.2mm.

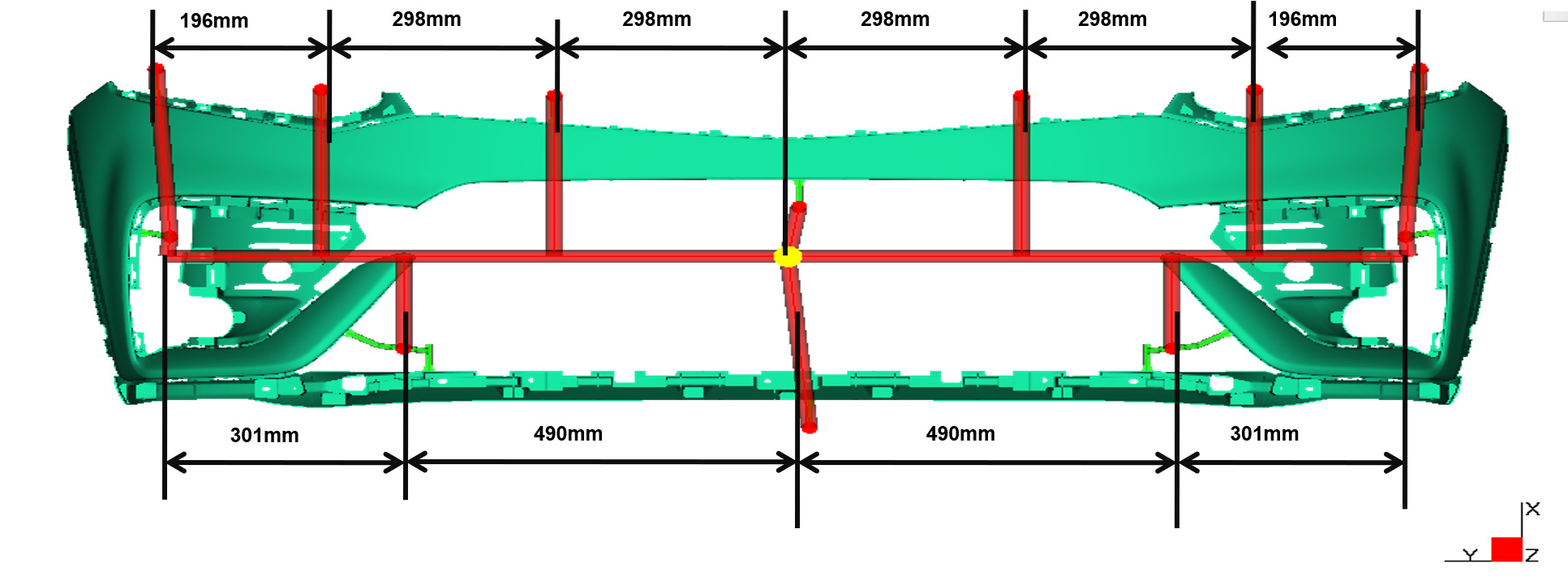

2.Hot runner scheme

2.Hot runner scheme

The hot runner scheme using Synventive Sequence valve gate 12 drops.

3.Simulated fill time (About 7.1s)

3.Simulated fill time (About 7.1s)

4.Cavity parting technology

The internal parting bumper is perfectly injection-molded at one time through the secondary track change track control technology, therefor ensuring the appearance quality of the bumper and saving the processing procedures and processing costs of plastic parts.

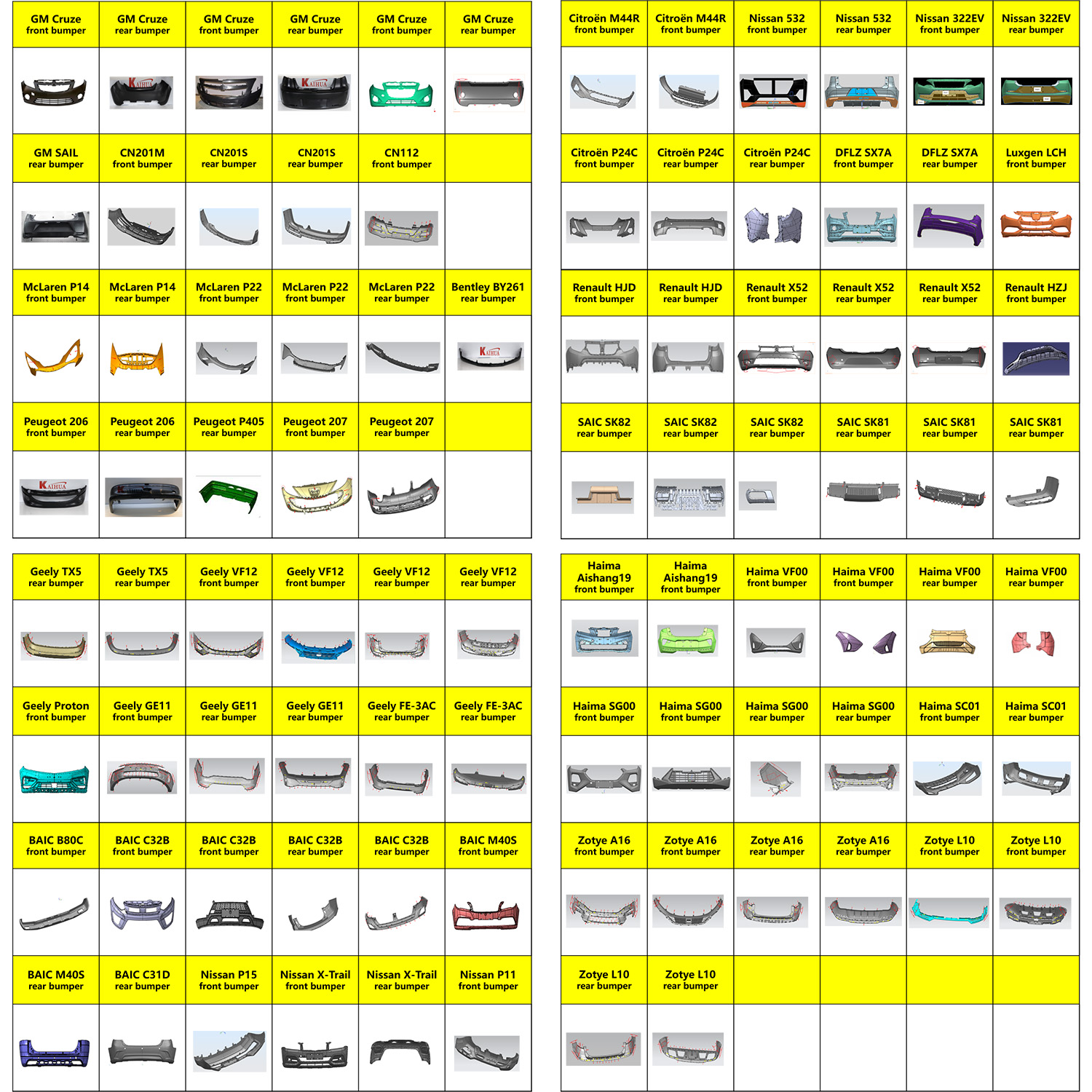

5. Cooperation Cases

With a full scientific excellent management process, great quality and excellent faith, we acquire very good standing and occupied this industry for 22 Years Factory Custom Made Plastics Injection Mould for Car Bumper Parts, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

22 Years Factory China Molding and Plastic Mold, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.