Equipment

-

Double Color Injection Machine

Kaihua Mold's Double Color Injection Machine allows for increased automation in the injection molding process. By automatically inserting and taking out parts, this machine reduces labor costs while improving production efficiency, quality, and capacity. Produced with precision and formality, this high-quality injection machine will ensure your manufacturing process runs smoothly and with optimal results. Trust in Kaihua Mold's Double Color Injection Machine to meet your injection molding needs. -

Belt Conveyor

At Kaihua Mold, we offer Belt Conveyor systems designed to quickly and efficiently transport materials in an automated and systematic manner. Our conveyors are engineered for reliability, durability, and high-performance in factory and industrial settings. With state-of-the-art technology and precision manufacturing, our Belt Conveyors are perfect for streamlining production lines and reducing human error. Whether you need a standard conveyor or a customized solution for your specific application, we have the expertise to deliver exceptional quality and performance. Trust Kaihua Mold to provide the ideal conveyor system for your business needs and experience the benefits of effortless material movement. -

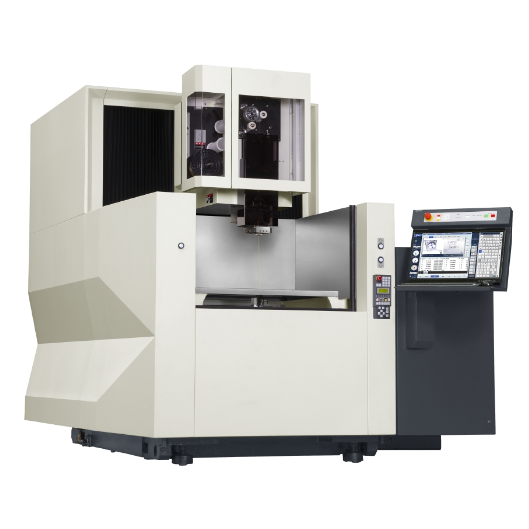

EDM

Kaihua Mold provides exceptional support for Electrical Discharge Machining, ensuring the efficient manufacture of various metal molds and mechanical equipment. Our equipment boasts an integrated structure, designed to tame thermal displacement and save space. With the latest technology, typically found in smartphones and tablet terminals, our control unit guarantees straightforward and intuitive operation. Whether you are in need of high-quality EDM support for your business or personal project, you can rely on Kaihua Mold to deliver exceptional results. -

Graphite Electrode Processing Machine

The Graphite Electrode Processing Machine, designed by Kailua Mold, utilizes advanced technology for high-speed and high-precision machining of graphite materials. Equipped with a spindle that minimizes vibration, this machine allows for optimal performance during high-speed rotation. Precise control technology ensures accuracy and efficiency in the manufacturing process. With its professional design, superior quality and precision, this product is the perfect solution for graphite electrode processing needs. Experience the excellence of Kailua Mold's Graphite Electrode Processing Machine and take your manufacturing capabilities to the next level. -

Milling Machine

Our Milling Machine, manufactured with the highest standards of precision and quality, guarantees accurate results and stable performance. Our guidance method ensures your work will stay on track without undesired variations in measurement. The handle is ergonomically designed for maximum comfort, so you can work for long periods without feeling fatigued. The smooth turning and high accuracy of our milling machine means that you can achieve your desired results without any difficulties. With Kaihua Mold, you can trust that you have the best equipment in the industry to solve your manufacturing needs. -

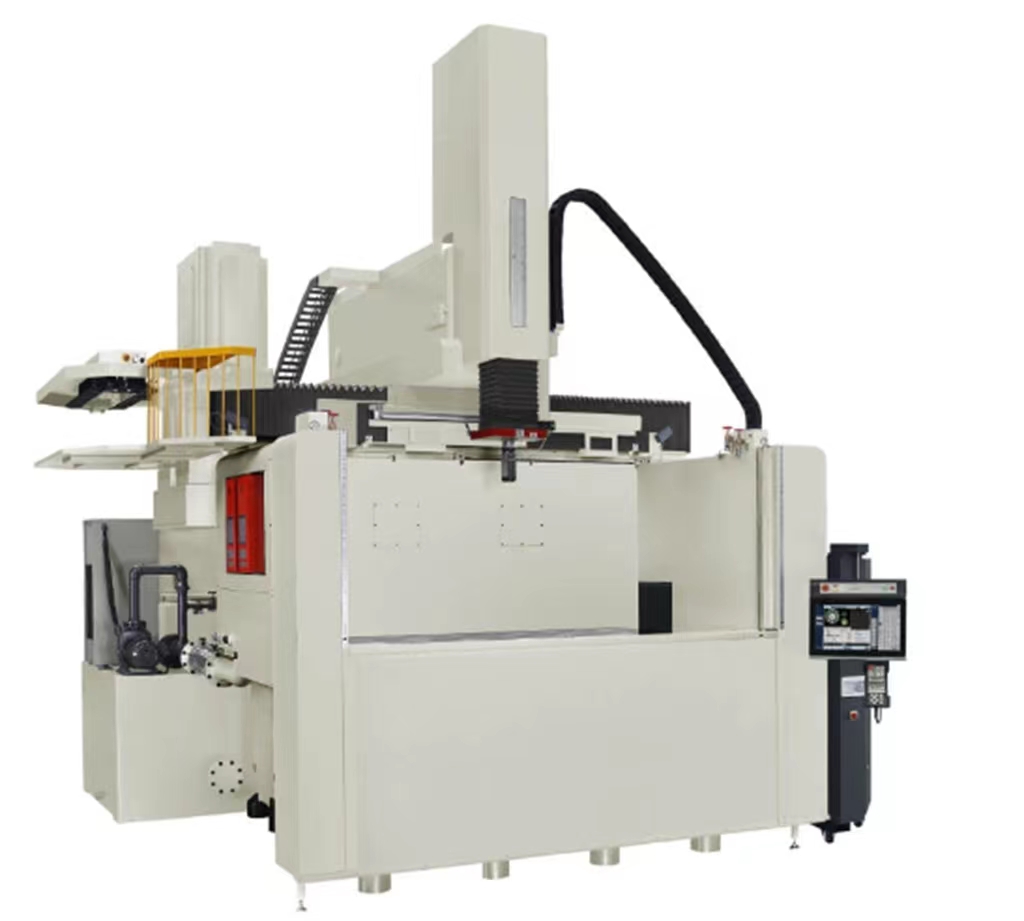

Die Spotting Machine

Our Die Spotting Machine is the perfect solution for kaihua mold. It allows for easy positioning of each part of the mold, ensuring a more ergonomic and safe closure. With this machine, you will no longer need cranes, forklifts, or other dangerous lifting equipment to match the mold. You can trust our machine’s professional and precise capabilities to accurately spot and check the mold for perfect closure. Experience a more efficient and effective mold-spotting process with our reliable and user-friendly Die Spotting Machine. -

Grinder

Our Grinder, designed and manufactured by Kaihua Mold, is a professional and precise tool that ensures high quality results. Equipped with electroplated grindstone measurement system, it achieves high speed and long tool life while maintaining pitch accuracy. Our grinder is the perfect choice for professionals who demand the best performance from their tools. Whether you are working in a shop or on a job site, Kaihua Mold's grinder is the tool you can rely on for precision and consistent results. Upgrade your tool collection today with our high-quality grinder. -

EDM Hole Drilling

Our EDM Hole Drilling technology is the perfect solution for accurately machining small deep holes in conductive metals. Using an energized rotating tube electrode and high pressure flushing, we are able to produce fast and precise results that meet the highest professional standards. Our advanced process is ideal for industries such as kaihua mold manufacturing, where accuracy and efficiency are paramount. We pride ourselves on delivering high-quality results every time, with a focus on meeting the unique needs and requirements of each individual customer. Trust us for all your EDM Hole Drilling needs and experience the difference that professionalism and precision can make. -

5-Axis Horizontal Machining Center

The 5-Axis Horizontal Machining Center is the perfect solution for machining complex geometric molds. Thanks to its additional rotation and swing capabilities, this state-of-the-art piece of equipment can help create better process conditions when machining deep and steep cavities. With a focus on precision and accuracy, this machine can help avoid the risk of tool, shank, and cavity wall damage, making it the ideal choice for professionals in the industry. Whether you're working in a small or large-scale operation, the 5-Axis Horizontal Machining Center from KiaHua Mold is the ultimate choice for high-quality machining. -

5-Axis Vertical Machining Center

Our 5-axis vertical machining center is specially designed for machining large and deep molds. With an inclined structure, it allows for efficient processing from the side. This machine is equipped with additional rotation and swing features, allowing for better process conditions and preventing any potential collisions between the tool, shank, and cavity wall. Designed for high precision and maximum efficiency, it is the perfect tool for mold machining applications. We are proud to serve clients like Kaihua Mold, with whom we have built a reputation for providing top-quality products that meet the highest industry standards. -

Vertical Machining Center

Kaihua Mold's Vertical Machining Center is the perfect solution for a wide range of parts processing needs, from semiconductors to medical equipment. With an oversized operation panel and advanced control device, this machine offers increased productivity and reduces worker fatigue. Ideal for industries such as aerospace, automotive, and more, the vertical machining center is designed to meet the highest standards of precision and quality. Whether you’re in need of rapid prototyping or high-volume production, Kaihua Mold’s vertical machining center is an essential tool for achieving your manufacturing goals. -

Horizontal Machining Center

The Horizontal Machining Center, manufactured by Kaihua Mold, is a game-changer in high-speed and high-performance spindles. Offering an exceptional chip removal rate, this machining center achieves high productivity and excellent quality under reasonable machining conditions. Equipped with cutting-edge technology, the Horizontal Machining Center is perfect for precision machining applications in industries like aerospace, automotive, and medical. With its advanced features and top-notch performance, this machining center is a true investment for any manufacturing facility looking to increase productivity, reduce costs, and improve the quality of their products.