Auto Airbag Mould Car Airbag Mold Automotive Injection Moulds

1.Product Introduction

Kaihua Mold is a global leader in Auto Airbag Mould manufacturing, specializing in Car Airbag Injection Mold solutions for driver, passenger, and side airbag covers. As a professional Automotive Mold Maker, we deliver molds featuring precision machining, advanced CAE flow analysis, and carefully engineered tear lines to ensure consistent performance under strict automotive safety standards. Common challenges such as uneven material flow causing warpage or sink marks, and tear line performance issues, are effectively resolved through optimized mold flow design, balanced cooling, and precise tear line engineering.

Leveraging decades of experience, Kaihua combines expert design, rigorous IATF 16949-compliant quality systems, lean manufacturing, and global support to provide Automobile Plastic Part suppliers with efficient, durable, and fully traceable mold solutions. Our expertise in large thin-wall components and lightweight automotive design ensures every mold meets both performance and aesthetic requirements for modern vehicles.

Alongside our car airbag molds, you can explore Mucell Dashboard Tooling and Auto Glove Box Mold, designed to meet the precise requirements of your automotive production projects.

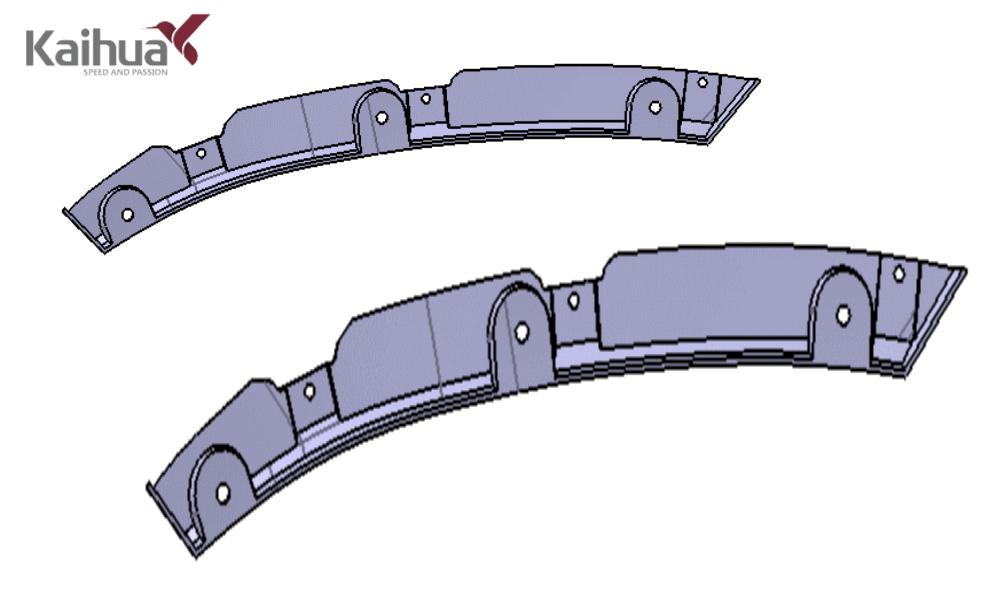

2.Product Display

| Part Name | PAB Cover |

| Mold size | 850*650*940 |

| Mold weight(t) | 3.65 |

| Product size(mm) | 516*172*168 |

| Product materials | TPO |

| cavity number | 1 |

| Part Name | DAB Cover |

| Mold size | 610*610*750 |

| Mold weight(t) | 1.7 |

| Product size(mm) | 207*173*111 |

| Product materials | TPO |

| cavity number | 1 |

3.Production details

|

Zhejiang Kaihua Moulds Co., Ltd. |

|||||

|

Speaker |

202 |

Air bag |

216 |

Handle |

196 |

|

Glove box |

420 |

Garnish license |

336 |

C-Pillar |

478 |

|

D-pillar |

520 |

Spoiler |

250 |

Door panel |

1550 |

|

Bumper |

1244 |

Backdoor |

286 |

Grill |

492 |

|

Mud guard |

500 |

Fog lamp |

216 |

Skirt |

381 |

|

Instrument Panel |

1500 |

Sunroof |

30 |

Etc. |

|

4.Product feature and application

(1) Product feature

● Advanced Flow & Thermal Management

● Our Auto Airbag Mould designs feature custom hot runner systems and 3D conformal cooling channels, ensuring uniform material flow and precise temperature control. This advanced engineering minimizes warpage, sink marks, and cycle time, enhancing production efficiency for TPO and other high-performance elastomers.

● Flawless Surface Quality

● Through ultra-fine polishing and optimized mold geometry, each Car Airbag Injection Mold delivers smooth, defect-free surfaces ideal for premium automotive interiors. Every cavity and tear line is meticulously crafted to meet strict aesthetic and functional standards expected from leading Automotive Mold Makers.

● Durability for Mass Production

● Constructed from high-grade mold steels, combined with advanced heat treatment and nitriding, these molds maintain dimensional stability over hundreds of thousands of cycles. This ensures long-term reliability, reduced maintenance, and consistent quality in producing Automobile Plastic Parts.

● Proven Safety & Performance

● Each mold undergoes rigorous CAE flow analysis, trial runs, and quality verification under IATF 16949 standards, ensuring precision and repeatability in every cycle. Our decades of expertise ensure that we can overcome challenges such as tear line misalignment or material inconsistencies, delivering safe, high-performance airbag molds trusted by global automotive brands.

(2) Product application

● Global Automotive OEMs & Tier-1 Suppliers: Our Injection Mould for Car Airbag solutions support the production of driver, passenger, and side airbag covers, enabling automotive manufacturers and Tier-1 suppliers to meet the industry’s strict safety, assembly, and reliability standards.

● Seamless Interior Fit: Each Car Interior Mold is precisely engineered to integrate seamlessly with dashboards, steering wheels, and seat modules, ensuring accurate alignment, consistent assembly, and premium aesthetic appeal inside modern vehicles.

● Flexible Production & Materials: Our Interior Automotive Molds are designed to support prototyping, small-batch validation, and scalable mass production, optimized for materials such as TPO, TPU, and other high-performance elastomers commonly used in airbag systems.

● Efficient & Eco-Friendly Manufacturing: By integrating optimized flow channels and 3D conformal cooling systems, our molds enhance production efficiency, reduce cycle time and material waste, and support automakers in achieving both performance and sustainability goals.

5.Kaihua Service

Choosing Kaihua means gaining more than a mold supplier — you gain a global partner:

● Engineering & Design Support – Our team provides in-house mold flow analysis and DFM consulting to help optimize airbag cover parts and injection molds for better performance and manufacturability.

● Turnkey Mold Solutions – From concept and prototyping to mold validation and full-scale production, we manage the entire process for a smooth and efficient delivery.

● Lean & Efficient Manufacturing – Using KMS and KMVE systems, we reduce waste, control costs, and ensure consistent high-quality molds without compromising performance.

● Post-Sales Training & Support – We offer on-site and online training for client teams on mold operation, maintenance, and troubleshooting, helping extend mold life and maximize production reliability.

● Kaihua's after-sales network spans worldwide, with full second-stage service support in Europe, North America, Thailand, and Malaysia, etc. Click to learn more about how Kaihua supports you after delivery.

At Kaihua, we are committed to delivering reliable, cost-efficient, and innovative Car Air Bag Mold solutions that support our customers' long-term success.

6.Product qualification

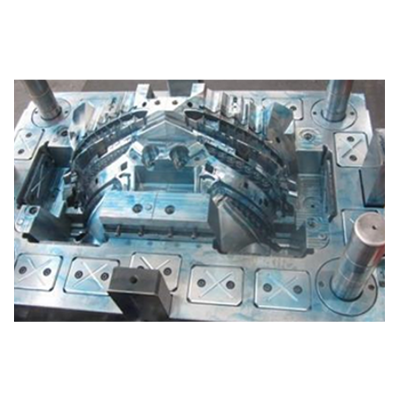

(1) Car Air Bag Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing Air Bags. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce pillar car parts that balance durability, structural integrity, and functional efficiency, suitable for a wide range of vehicle models.

(2) Product shipment and packaging photos

(3) Design review photos

(4) Photos of the Technical Department Meeting

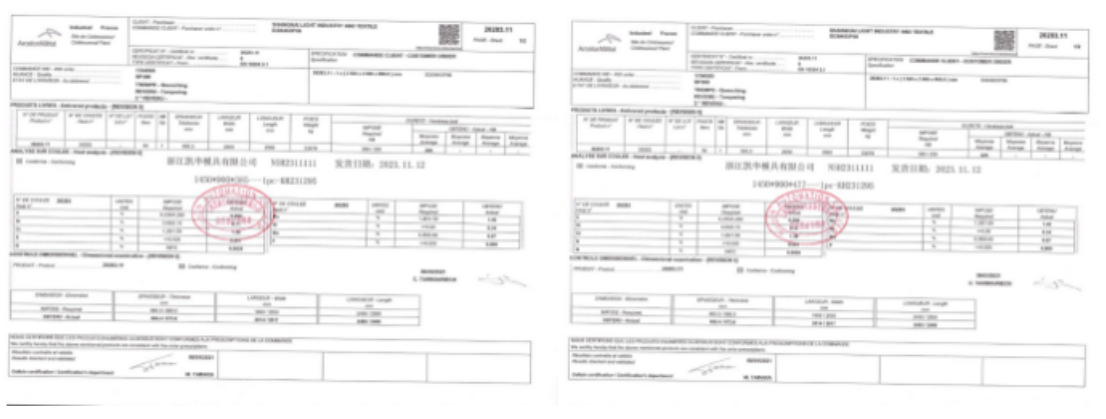

(5) Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.