Auto Glove Box Mold Automotive Mold Car Interior Mold

1.Product Introduction

As a top automotive mold manufacturer and trusted automotive mold supplier, Kaihua produces high-quality Car Glove Box Injection Molds for the global automotive market. We use top-notch steels: 1.2344/1.2343,1.2738HH,1.2738,718H,P20HH, etc.. Brands include Germany's Buderus, Lurgi, and Böhler, ensuring mold durability and precision. With over 20 years of experience, our molds—trusted by Tesla, Geely, and Toyota—achieve industry-leading 0.001mm precision, thanks to processing by Japanese MAKINO and German DMG 5-axis machines.

Kaihua’s glove box molds last over 500,000 cycles and work seamlessly with automatic injection molding machines (KraussMaffei, Haitian) for 70-second standard production cycles. Every mold holds ISO 9001:2015 and IATF 16949 certifications, and undergoes strict pre-shipment tests (CMM checks, 2,000 dry cycles) to guarantee quality.

Additionally, Kaihua's expertise in automotive interior molds (such as dashboard mold and door panel mold) allows us to optimize glove box mold designs for seamless integration with other interior components, meeting global automakers' assembly standards.

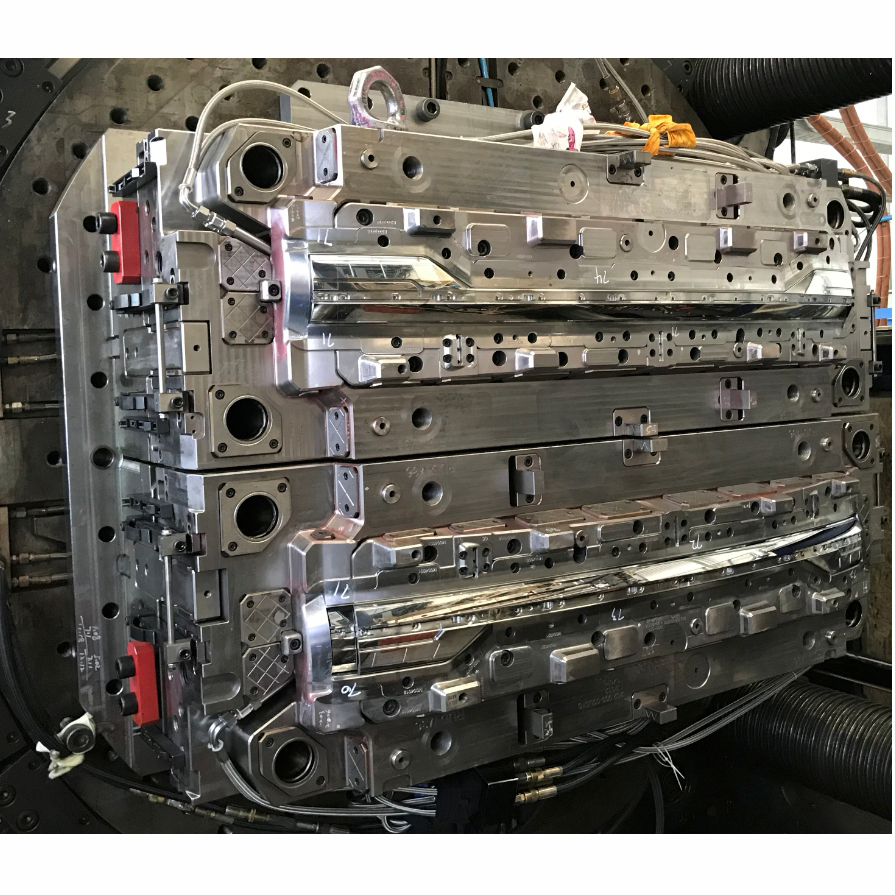

2.Product Display

|

Product Name |

Glove Box Outer Lid |

|

Plastic Material |

PC/ABS/ABS/PC/PVC/PA66/POM/Customized |

|

Injection Molding Machine Tonnage |

470T/650T/800T/100T/1200T/Customized |

|

Number of Mold Cavities |

Single Cavity / Family Molds / Multi Cavity |

|

Mold Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Grain or Electroplate |

Grain |

|

Automatic Demolding Requirements |

Robot |

|

Hot Runner Brand |

Cold/Hot Runner |

|

Product Name |

Glove Box Outer Lid |

|

Plastic Material |

PC/ABS/ABS/PC/PVC/PA66/POM/Customized |

|

Injection Molding Machine Tonnage |

470T/650T/800T/100T/1200T/Customized |

|

Number of Mold Cavities |

Single Cavity / Family Molds / Multi Cavity |

|

Mold Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Grain or Electroplate |

Grain |

|

Automatic Demolding Requirements |

Robot |

|

Hot Runner Brand |

Cold/Hot Runner |

3.Product Display

4.Product feature and application

(1) Product feature

● Advanced Tooling Technology

Kaihua Mould produces each Carbon Fiber Bumper Plastic Injection Mold with high-precision CNC machining, milling, and EDM. Our Bumper Injection Molds deliver complex geometries accurately, suitable for both OEM Bumper Moulds and Custom Injection Molds.

● Superior Surface Finish

Polishing and texturing follow strict international standards, ensuring Car Bumper Moulds achieve smooth, Class A surfaces while maintaining dimensional accuracy.

● Efficient Cooling Design

Optimized cooling channels in every Automotive Bumper Mold reduce cycle times, improve consistency, and enhance production efficiency for high-volume Auto Parts Injection Mold projects.

● Flexible Customization

Kaihua adapts design, steel selection, and tooling to customer requirements, supporting lightweight, durable Auto Bumper Moulds and tailored Custom Injection Mold solutions.

● Short Lead Times

Integrated in-house design, machining, and trial capabilities allow faster delivery from prototype Auto Parts Mold to full-scale production, keeping projects on schedule.

● Reliable Global Support

Overseas technical assistance ensures smooth installation, trial runs, and maintenance. Every Bumper Mold is backed by strict quality control and responsive after-sales service.

(2) Product application

● OEM Car Bumpers – Mass-produce front and rear bumpers with precise fit.

● Custom & Performance Bumpers – Limited edition or aftermarket designs using Car Bumper Moulds.

● Integrated Body Kits – Produce multiple coordinated bumper components with Auto Parts Molds.

● Prototyping & Small Batches – Rapid tooling for new designs or concept vehicles

● High-Volume Production – Scalable Auto Bumper Moulds for large-scale manufacturing.

Benefits: Consistent part quality, reduced waste, and flexible production for standard or custom bumpers.

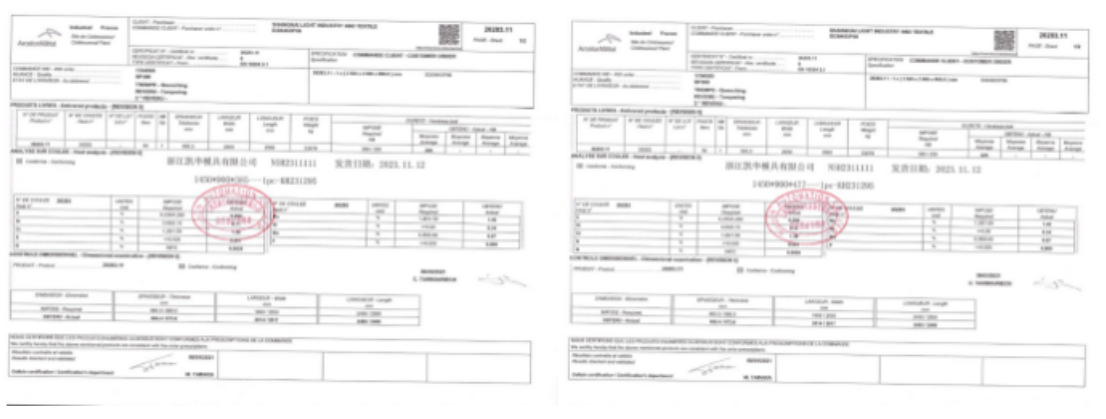

5. Prodect qualification

(1) Auto Glove Box Injection Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing vehicle air grilles. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce air grilles that balance durability, visual appeal, and functional efficiency, suitable for a wide range of vehicle models.

(2) Product shipment and packaging photos

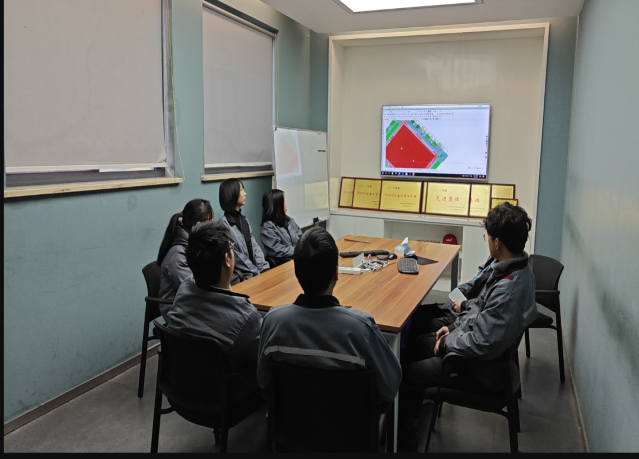

(3) Design review photos

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.