Gas-Assisted Door Panel mould for injection moulding

1.Product Introduction

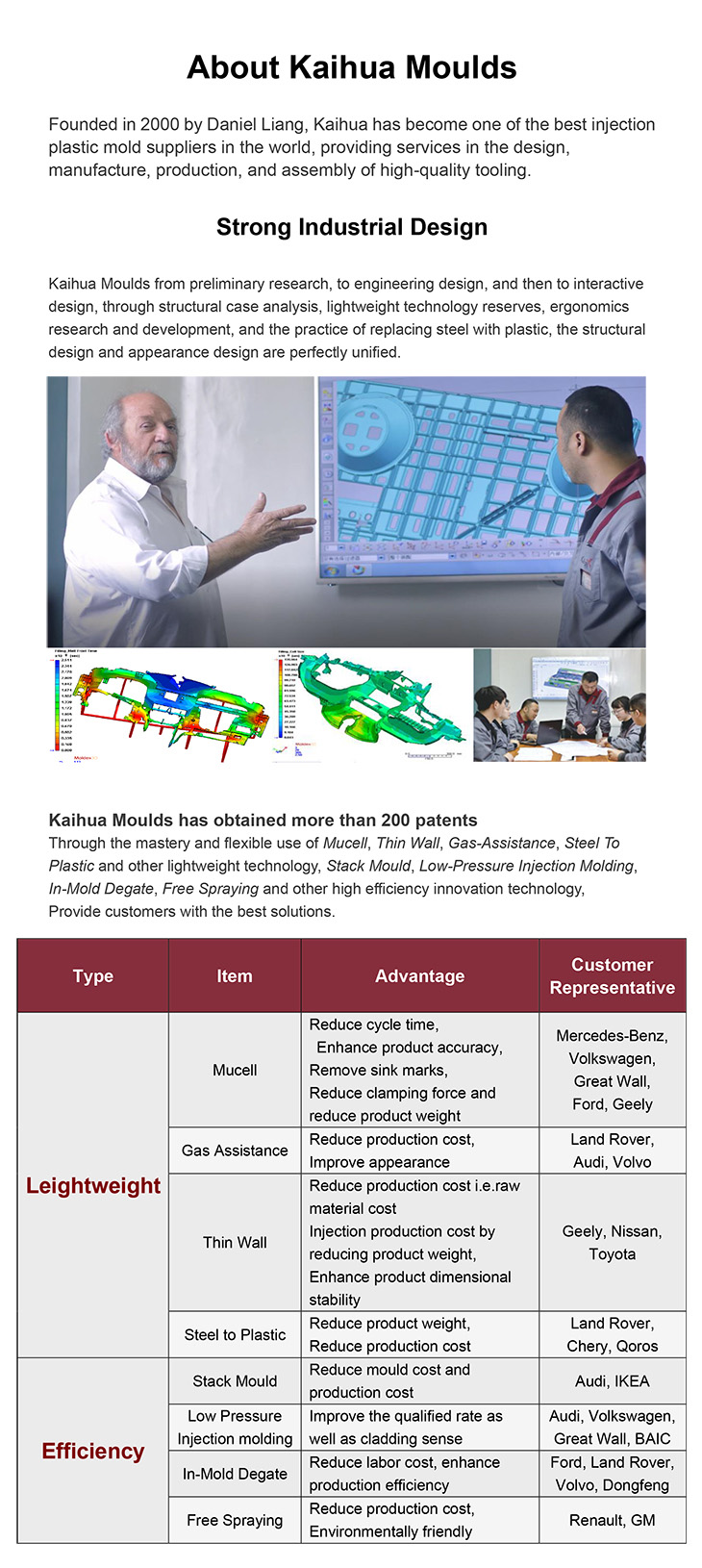

Building on its long-standing expertise in automotive injection molds, Kaihua Moulds has developed a line of gas-assisted door panel molds that set new performance standards for modern vehicle interiors. Designed for premium programs like the Jaguar XF, these car door panel molds combine lightweight design, high surface quality, and precise dimensional control through an advanced gas-assisted injection molding process.

Kaihua's system uses high-precision gas needles for controlled nitrogen injection, forming uniform hollow structures that reduce material use while maintaining strength. Coordinated overflow and exhaust controls help eliminate internal stress and surface defects, ensuring a smooth finish even on large or complex car interior components.

Equipped with dual hot runner systems from leading suppliers such as Synventive, YUDO, and HRS, the molds deliver balanced flow and accurate temperature control, critical for intricate features like speaker grilles and map pockets. This allows consistent part quality and up to 40% lighter door panels, supporting vehicle lightweighting and efficiency goals.

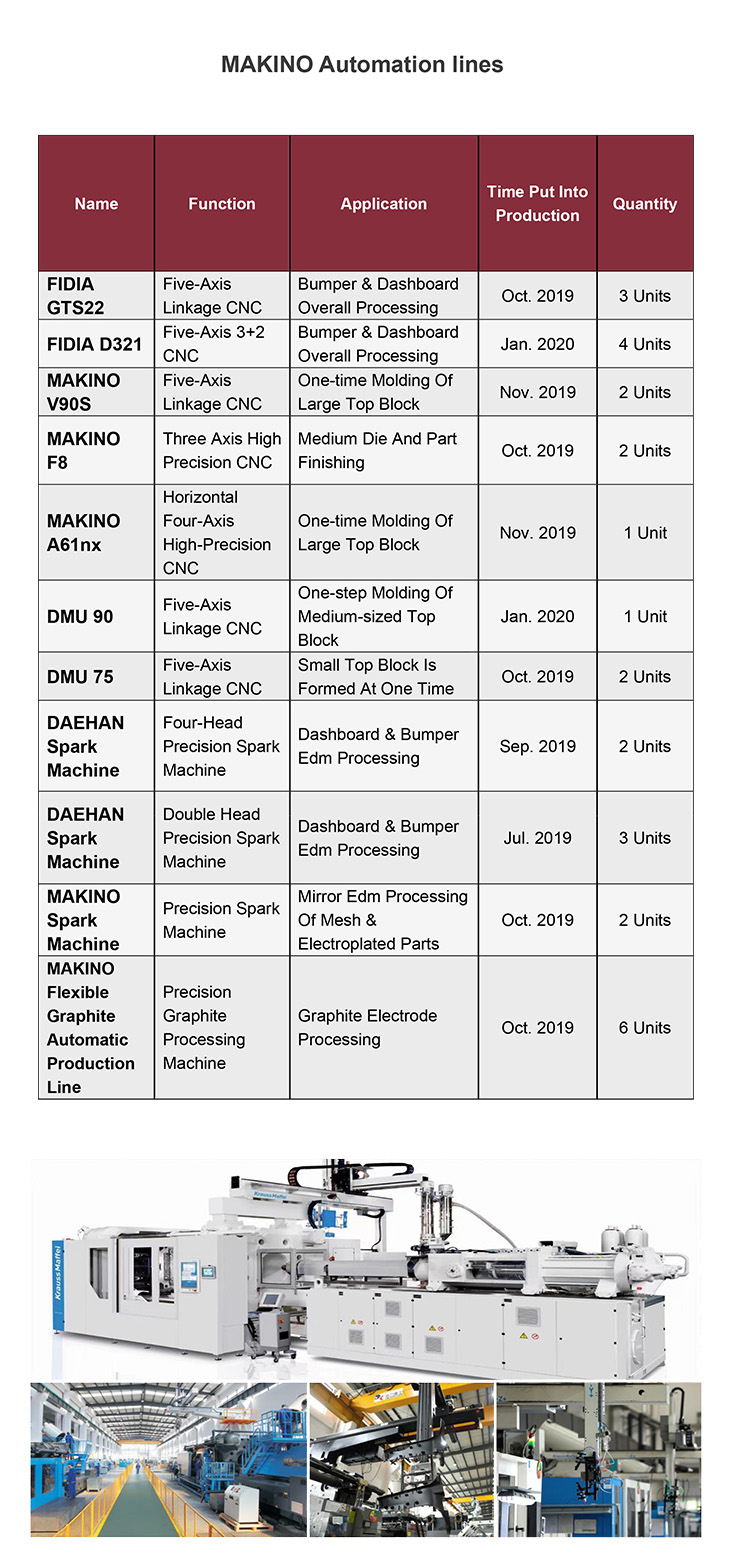

With three advanced production facilities, over 1,900 skilled staff, and precision equipment including FIDIA 5-axis CNC centers and HEXAGON CMMs, Kaihua ensures long-lasting, reliable molds. Trusted by OEMs like Audi and Volvo and Tier-1 suppliers such as Yanfeng and Magna, Kaihua is recognized as a leading automotive mold manufacturer and car injection mold maker.

In addition, two flagship models of Kaihua's Automobile Plastic Injection Molds—the Center console mold and the Car door mould—have garnered extensive recognition across the industry.

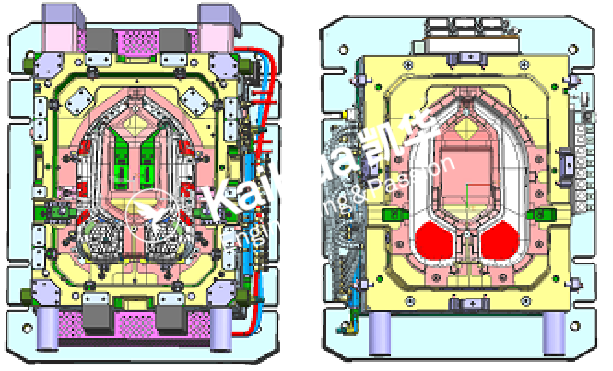

2.Product Display

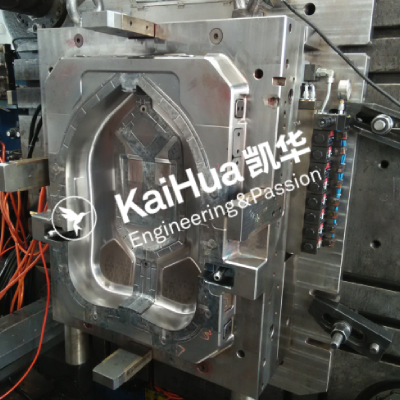

3.Production details

4.Product feature and application

(1) Product feature

●Dynamic Gas-Assisted System Control

Equipped with a cylinder-driven gas needle adjustment structure, the gas-assisted door panel mold can flexibly control high-pressure nitrogen injection timing and pressure according to the specific requirements of different door panel areas. This reduces issues such as melt penetration and local bulging caused by improper gas control. Paired with an overflow-exhaust linkage module, excess melt generated during the gas-assisted process is collected automatically, and residual pressure in the mold cavity is released in time. The result is a significant reduction in defects like surface sink marks and internal bubbles, ensuring high-quality car door panel molds .

●Highly Adaptable Cavity Design

The mold cavity is machined from premium steel (e.g., Buderus 2738) and optimized for complex door panel structures, such as speaker grilles and map pocket reinforcing ribs. This ensures uniform melt flow, improves the cavity's durability under repeated injection cycles, minimizes dimensional deviations, and extends the service life of the automotive mold.

● Modular Quick-Change Structure

A modular split design accommodates structural differences between door panels of various vehicle models. When adapting to a new model, only local modules—such as gas needle mounting components or partial cavity inserts—need replacement, and process parameters are adjusted accordingly. This shortens adaptation cycles, improves production flexibility, and makes the mold highly efficient for multiple car interior mold applications

(2) Product application

● Door Panel Production for Multi-Grade Vehicle Models

These car door panel molds are suitable for luxury sedans (e.g., Jaguar XF front and rear door panels), mid-to-large SUVs (e.g., Audi Q7 door panels), and mainstream family sedans (e.g., Ford CD391 series). Depending on the vehicle grade, the molding process can be optimized for surface precision in luxury models or balanced for cost and structural strength in family vehicles.

●Automotive Lightweight Upgrade Projects

Using gas-assisted injection molding, the molds create hollow structures inside the door panels, achieving material weight reduction of 20%-40% in some projects. This supports fuel-efficient traditional vehicles and helps new energy vehicles reduce body weight, improving driving range.

● Mass Production for Tier-1 Suppliers

The molds support multi-cavity designs and efficient molding processes to increase daily output. This meets the production needs of Tier-1 suppliers, ensuring stable supply of car door panel molds for automakers' assembly lines.

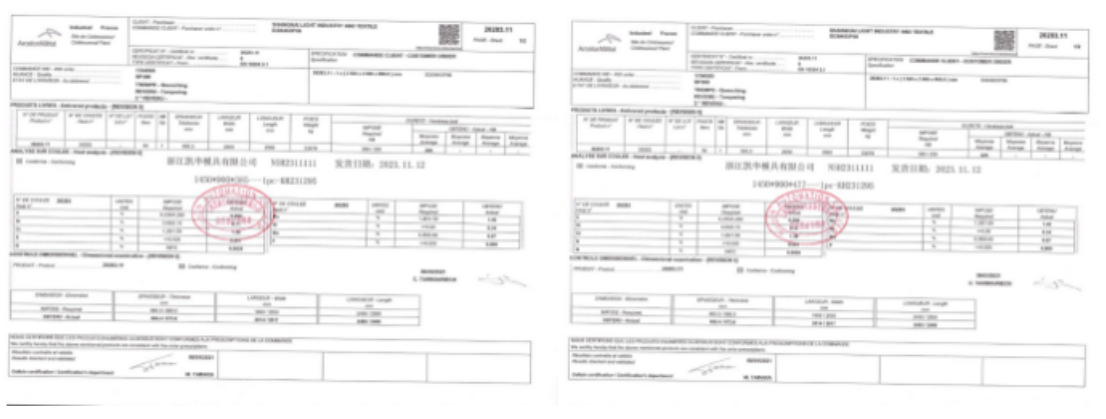

5.Product qualification

(1)Gas-Assisted Door Panel Molds Trial Process

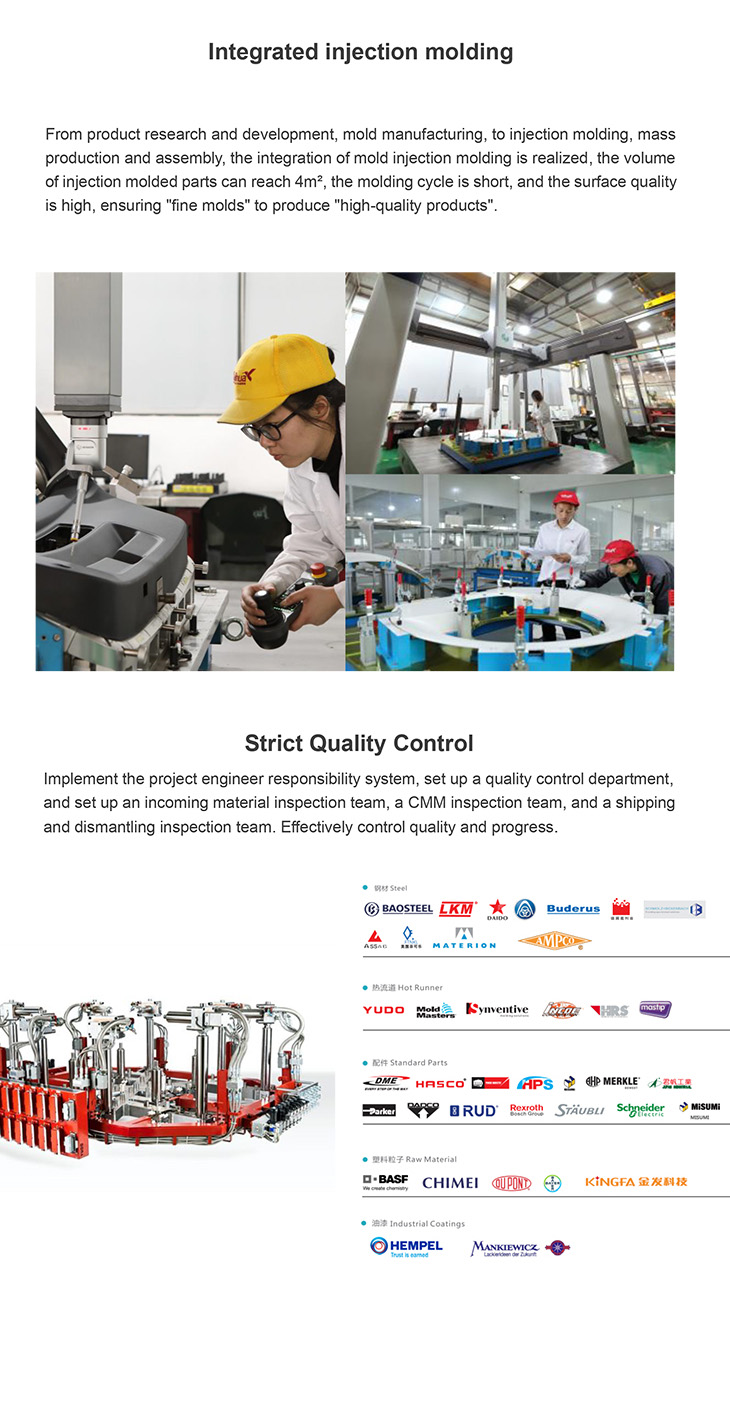

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing Gas-Assisted Door Panel. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce air grilles that balance durability, visual appeal, and functional efficiency, suitable for a wide range of vehicle models.

(2)Product shipment and packaging photos

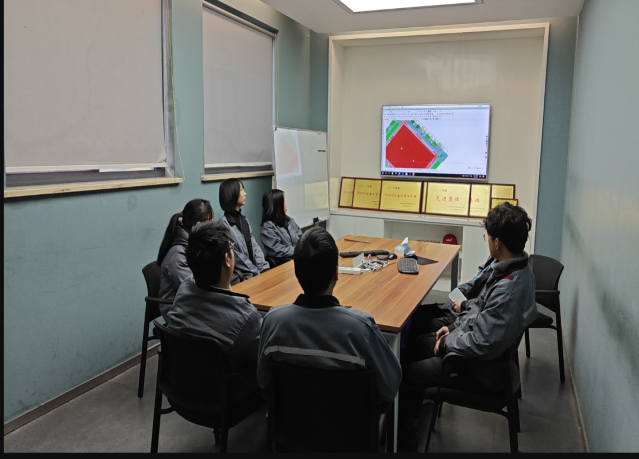

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here