Car Door Panel plastic Mold Automotive Injection Moulds Door Panel

1.Product Introduction

Kaihua Mould specializes in manufacturing Car Door Panel Molds—a core product line that integrates large-scale precision, lightweight engineering, and Class-A surface quality—tailored to meet the rigorous demands of automotive exterior and interior production. As a trusted partner for global automotive manufacturers, we don't just stop at standard Car Door Panel Plastic Molds; our expertise extends to a full range of Automotive Molds, including specialized Interior Automotive Molds and Car Interior Molds, ensuring we cover both exterior durability and interior aesthetics for diverse vehicle models.

Designed for seamless compatibility with high-volume manufacturing, our Car Door Panel Molds enable producers to craft door panels with robust structural strength, ultra-high dimensional accuracy, and consistent quality—effectively solving common pain points like uneven shrinkage or surface defects in Door Panel Molding processes. Backed by over 20 years of industry experience and a dedicated team of 200+ engineers, we deliver customized solutions for global OEMs and Tier-1 suppliers, whether for passenger cars, SUVs, or electric vehicles. Beyond mold production, we provide end-to-end support to optimize Door Panel Molding efficiency, ensuring faster cycles, reliable long-term mold performance, and alignment with the production needs of even the most complex Automobile Plastic Part manufacturing workflows.

Beyond the car door panel molds introduced above, you can also explore our Automotive Light Housing Injection Mold and Car Bumper Mould – two more automotive component solutions tailored to meet your specific needs.

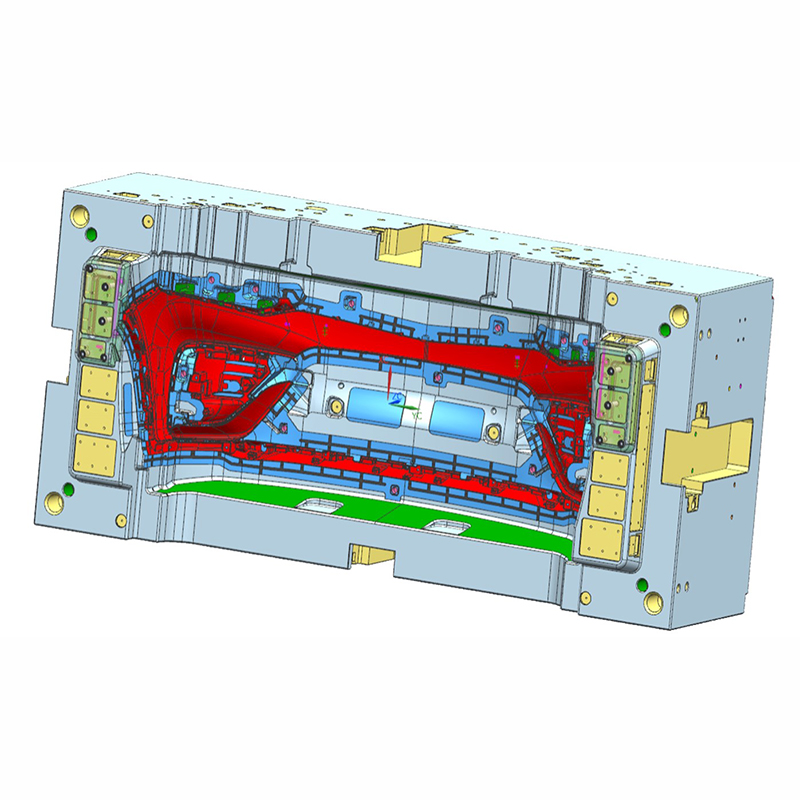

2.Product Display

| Part Name | left rear door inner panel |

| Mold size | 1450X1300X1130 |

| Mold weight(t) | 1.18 |

| Product size(mm) | 783X631X140 |

| grain or electroplate | Grain |

| Demolding requirement | Gripper |

| Product materials | PP+EPDM-T20 |

| Injection Machine(t) | 1600 |

| cavity number | 1+1 |

| Part Name | Left/Right front door center trim panel |

| Mold size | 1150X850X840 |

| Mold weight(t) | 5.479 |

| Product size(mm) | 823X232X66 |

| grain or electroplate | Covering |

| Demolding requirement | Gripper |

| Product materials | ABS |

| Injection Machine(t) | 1000 |

| cavity number | 1+1 |

Left front door inner panel

Right front door inner panel

Front door scuff plate inner panel

Rear door scuff plate inner panel

Right rear door inner panel

Left and right front door scuff plates

Left/Right door map pocket

Left/Right front door inner release handle cover

Left/Right front door armrest

Left/Right front door switch panel

Left and right front door armrest frame

Left and right front door tweeter bracket

3.Production details

4.Product feature and application

(1) Product feature

● Unmatched Accuracy

Our advanced 5-axis machining centers deliver high-level precision, even for oversized car door panel molds. This guarantees perfect fit of mounting holes, hinges, and edge seams—eliminating assembly issues and ensuring reliable performance in mass production.

● Smart Flow & Cooling Control

With tailor-made hot runner systems and 3D-printed conformal cooling channels, we ensure stable melt flow and efficient cooling. For reinforced PP+T20 materials, this means less warpage and shorter cycle times—boosting both quality and productivity.

● Premium Surface Finishes

Our ultra-fine polishing process allows molds to deliver flawless high-gloss or textured surfaces. The finished door panels meet the standards for direct application in premium automotive interiors, delivering enhanced aesthetics and durability while maintaining minimal defects.

● Durability That Lasts

We use certified high-grade steels such as 1.2344/1.2343,1.2738HH and 1.2738, combined with advanced heat treatment and nitriding. This ensures stable precision for over 0.5 million cycles and reduces maintenance needs, giving you a mold built for long-term performance.

(2) Product application

● Global Automotive OEMs & Tier-1 Suppliers: Our Car Door Panel Molds support high-volume production of exterior/interior door panels for passenger cars, SUVs, and EVs, solving mass manufacturing efficiency/quality challenges for global partners.

● Premium Vehicle Interiors: Delivers Class-A surface finishes for Car Interior Molds, enabling direct assembly in luxury vehicles while meeting strict aesthetic and durability standards.

● EV Lightweighting Goals: Integrates lightweight tech to reduce Automobile Plastic Part weight, perfectly aligning with electric vehicle requirements for improved energy efficiency.

● Diverse Material Compatibility: Optimized for PP+T20 glass fiber, ABS resin, etc., our Automotive Molds ensure stable molding of strong, dimensionally accurate door panels.

● Aftermarket & Customization: Our Car Door Panel Plastic Molds cater to aftermarket suppliers and custom shops, supporting small-batch replacement panels or personalized designs with OEM-grade precision.

● Sustainable High-Cycle Lines: Ensures 0.5M+ reliable production cycles with efficient cooling/flow systems; cuts waste via precise control and supports recyclable plastics, meeting sustainability and high-output goals.

5.Kaihua Service

Choosing Kaihua means gaining more than a mold supplier — you gain a global partner:

● Engineering Support – In-house mold flow analysis and DFM consulting for optimized part and mold design.

● Turnkey Project Management – From concept and prototyping to mold validation and mass production.

● Lean Manufacturing – Guided by KMS and KMVE systems, reducing waste and controlling cost without sacrificing performance.

● Post-sales training: Provides online/on-site training for client teams on mould operation, maintenance, helping avoid improper use and extend mould lifespan, complementing technical support.

● Kaihua's after-sales network spans worldwide, with full second-stage service support in Europe, North America, Thailand, and Malaysia, etc. Click to learn more about how Kaihua supports you after delivery.

At Kaihua, we are committed to delivering reliable, cost-efficient, and innovative Car Door Panel Mold solutions that support our customers' long-term success.

|

Zhejiang Kaihua Moulds Co., Ltd. |

|||||

|

Speaker |

202 |

Air bag |

216 |

Handle |

196 |

|

Glove box |

420 |

Garnish license |

336 |

C-Pillar |

478 |

|

D-pillar |

520 |

Spoiler |

250 |

Door panel |

1550 |

|

Bumper |

1244 |

Backdoor |

286 |

Grill |

492 |

|

Mud guard |

500 |

Fog lamp |

216 |

Skirt |

381 |

|

Instrument Panel |

1500 |

Sunroof |

30 |

Etc. |

|

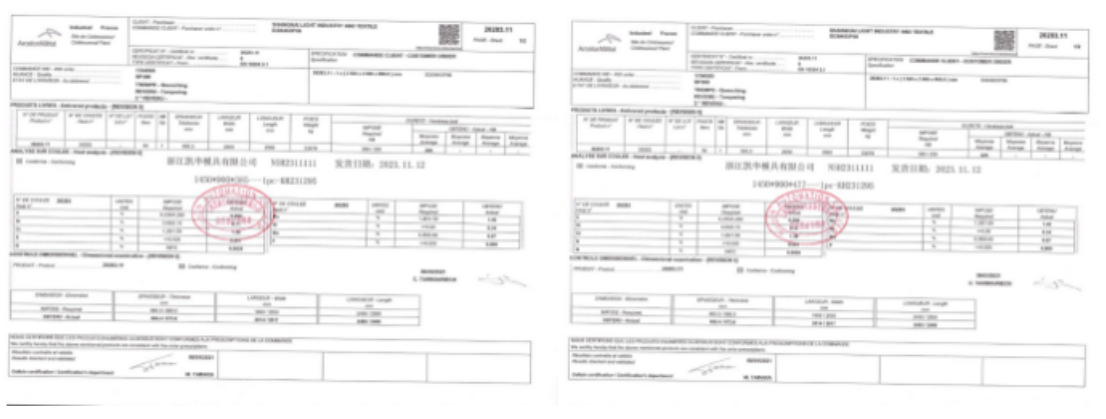

7.Product qualification

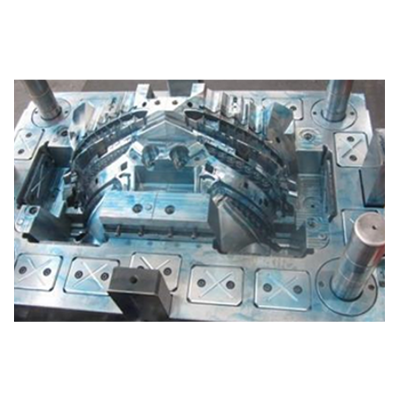

(1)Car Door Panel Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing car door panels. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce pillar car parts that balance durability, structural integrity, and functional efficiency, suitable for a wide range of vehicle models.

(2)Product shipment and packaging photos

(3) Design review photos

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

8.Kaihua Mould Advantage

9.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.