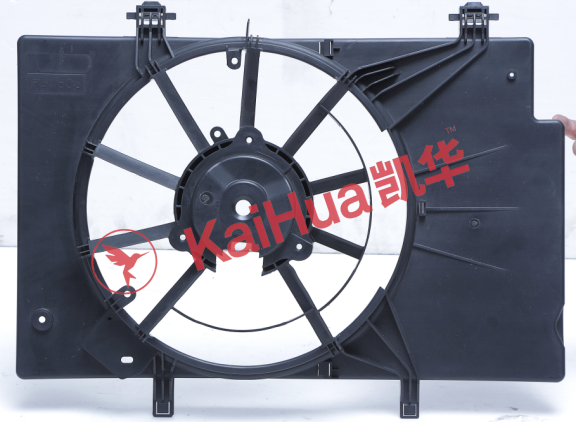

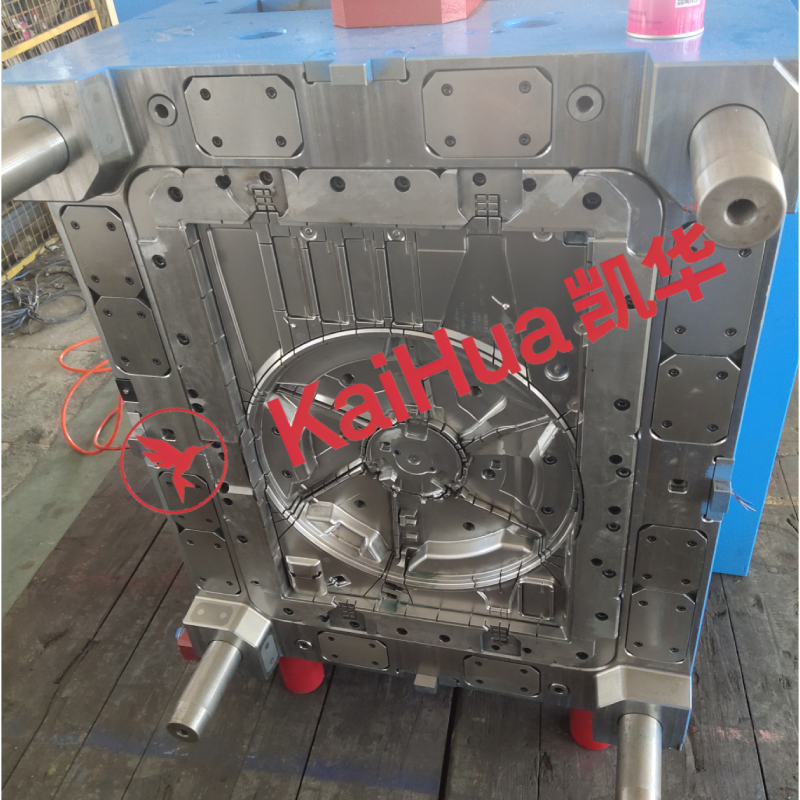

Car Fan Shroud Injection Mould Car Part Mold

1.Product Introduction

As a leading automotive mold manufacturer, Kaihua Mould leverages deep expertise in large-scale aerodynamic components to deliver high-performance solutions for modern vehicle cooling systems.

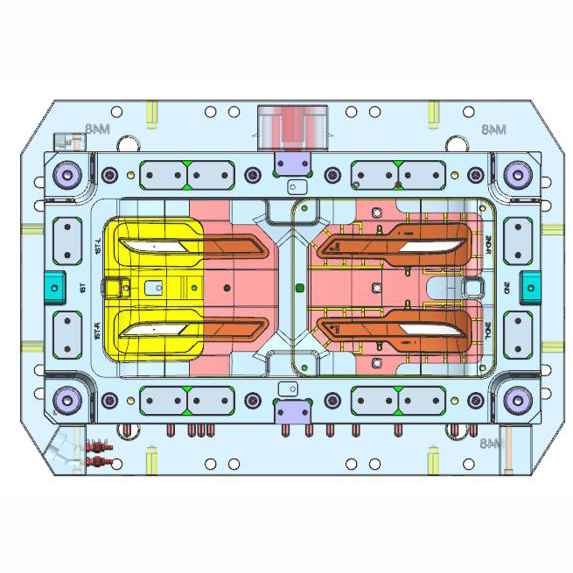

Our molds for cooling fan shrouds are engineered to solve the most critical challenges—warpage control, dimensional stability, and aerodynamic efficiency. Through CAE-optimized gating and cooling systems, we achieve uniform filling and precise temperature control across large surfaces, ensuring exceptional flatness and tight dimensional tolerances. Each mold design integrates reinforced structural zones for strength, precision-machined aerodynamic surfaces for optimized airflow, and proprietary venting channels that eliminate trapped air and weld lines, guaranteeing consistent material density and surface quality.

Every mold undergoes rigorous endurance testing and CMM dimensional verification before shipment, ensuring stable performance under real-world production conditions. Backed by TÜV Rheinland ISO 9001: 2015 certification and over 25 years of engineering excellence, Kaihua Mould is a trusted partner to global automotive leaders such as FAURECIA and IAC—delivering molds that combine precision, efficiency, and long-term reliability.

In addition, Kaihua Mould's flagship Automotive Interior Mold and Exterior Moulds have been widely recognized for their superior engineering and exceptional performance — further demonstrating our leadership in precision tooling for advanced vehicle design and manufacturing.

2.Product Display

|

Product Name |

Plastic Auto Fan Shroud Injection Mould |

|

Part Material |

PA6-GF30/PA66-GF30/PPS/PPA/ customized |

|

Mold Steel Material |

1. 2738 Buderus/P20 Fink/2738H/Customized |

|

Product Surface Requirement |

Texture (Gas-Assisted) /Grain/Customized |

|

Injection Molding Machine Tonnage |

1000T/1250T/ Customized |

| Number of Mold Cavities | 1/1*1/Customized |

|

Cold/Hot Runner |

Cold/Hot Runner |

| Hot Runner Brand | YUDO/Synventive/Mold-Masters/ HRS/ INCOE/ Customized |

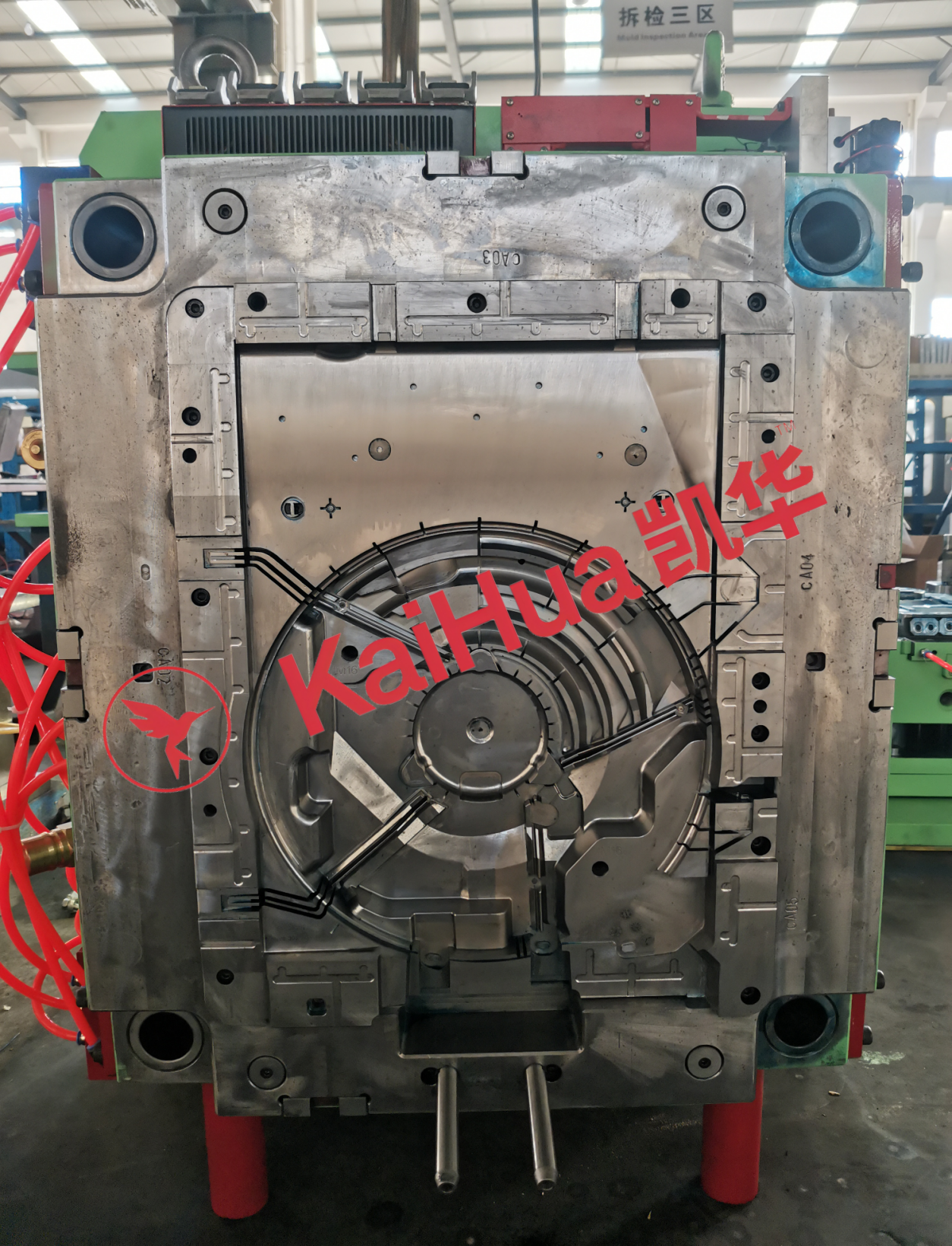

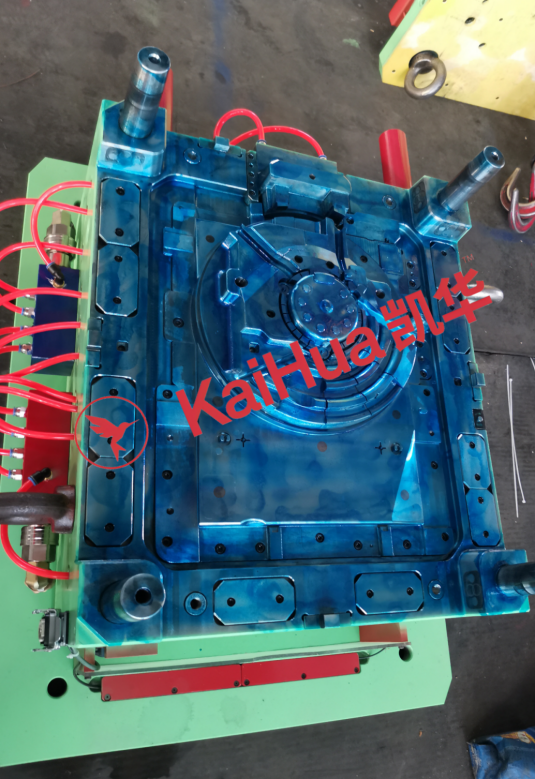

3.Production details

4.Production details

5.Product feature and application

(1) Product feature

● Vehicle-Specific Mold Architecture

Each mold is engineered around your exact vehicle platform, incorporating customized cooling channel layouts, modular insert systems, and optimized structural reinforcement. The mold configuration precisely matches your shroud geometry, ensuring superior performance for every thermal management requirement.

●Adaptive Manufacturing Technology

Kaihua's flexible mold systems support a range of production processes, including gas-assisted and thin-wall molding. This adaptability allows precise balance of weight reduction, mechanical strength, and cooling efficiency—without compromising productivity or cycle time.

●l Advanced Thermal&Flow Management

Precision-machined conformal cooling channels follow complex part geometries for uniform temperature control, effectively preventing warpage and maintaining±0. 5 mm dimensional accuracy. A scientifically designed runner and venting system ensures complete filling, eliminates trapped air, and prevents weld lines or burning defects.

● Brand-Exclusive Surface&Structural Solutions

We integrate brand-specific surface textures, identification marks, and refined surface treatments directly into the mold structure. Combined with robust Buderus 2738 steel construction, this delivers shrouds that reflect both your brand identity and long-term production reliability.

l Collaborative Design Integration

Our engineering team works closely with your design and production teams to refine performance-critical details throughout development. This collaborative approach ensures that every mold exceeds standard specifications and directly addresses your unique manufacturing challenges.

● Modular Component Integration

Standardized, interchangeable inserts and guided ejection systems simplify maintenance and future modifications, significantly reducing downtime and extending mold service life in high-volume production.

(2) Product application

●Platform-Optimized Performance

Each mold is precisely calibrated to your cooling module layout—whether for compact EVs, SUVs, or heavy-duty trucks—ensuring perfect fit and seamless integration with radiator, fan, and ducting assemblies.

● Production-Validated Reliability

Every mold undergoes comprehensive endurance and simulation testing under actual production conditions. Combined with CMM dimensional verification, this ensures consistent precision and reliability from the first production run onward.

●Global Support Integration

With 15 global branches and local service teams, Kaihua provides on-site technical support aligned with your production schedule and quality systems. From design kickoff to SOP, we ensure smooth implementation across your global manufacturing footprint.

●Quality Assurance Partnership

We integrate our quality control framework with your existing systems, employing advanced inspection and real-time data validation to deliver consistent, repeatable results. This partnership approach guarantees that every shroud meets your precise dimensional, mechanical, and performance standards.

Backed by TÜV Rheinland ISO 9001: 2015 certification and over 25 years of automotive tooling expertise, Kaihua Mould is the trusted partner of global OEMs and Tier-1 suppliers including FAURECIA and IAC—delivering precision, reliability, and innovation in every mold.

6.Kaihua Service

●Global Technical Network

With 15 international technical centers spanning Europe,Americas and Asia,we provide localized engineering support and rapid response services.

●Expert Engineering Team

Our 180-member design team and 350 certified technicians deliver professional DFM analysis and continuous technical guidance.Each project is assigned a dedicated project manager who maintains transparent communication and provides regular progress updates.

●Advanced Manufacturing Facilities

Our smart factory integrates MAKINO graphite machining centers and automated lifter systems within fully automated lines, supporting autonomous, round-the-clock operations for uninterrupted production.The 251,300m²manufacturing base is equipped with high-precision inspection equipment from Germany WENZEL and Sweden HEXAGON.

●Proactive Service System

We implement KMS lean management to eliminate 9 types of production wastes,ensuring optimal efficiency.Our service includes comprehensive operator training,efficient spare parts supply,and regular performance follow-ups to maximize your production uptime.

●Total Quality Assurance

Backed by ISO 9001:2015 certification and 44 quality engineers,we implement rigorous quality control throughout the manufacturing process.Each project undergoes multiple inspection checkpoints and comprehensive testing before delivery.

●Lifetime Partnership Commitment

Beyond mold delivery,we provide lifetime technical support and maintenance services.Our global spare parts network and regular maintenance recommendations help extend mold service life and optimize your long-term production costs.

With 25 years of automotive mold expertise and continuous improvement through KMS,we are committed to being your reliable manufacturing partner for sustainable production success.Click to learn more about how Kaihua supports you after delivery.

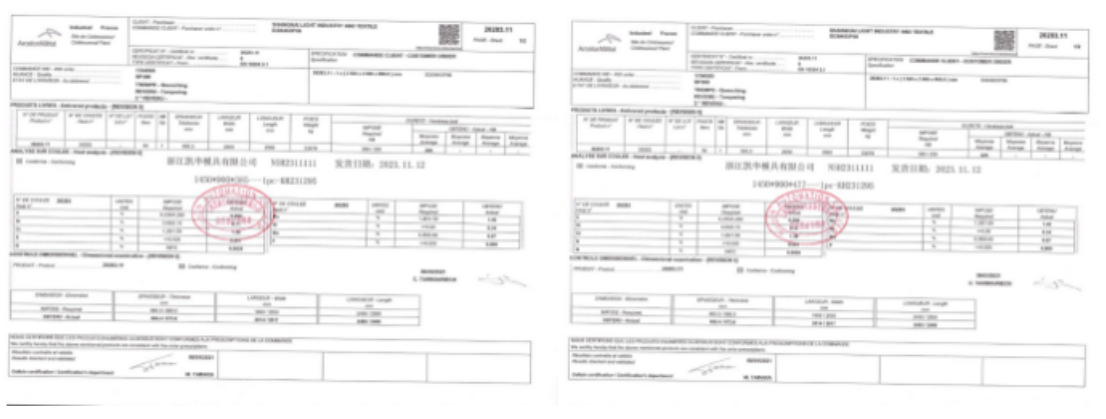

7.Product qualification

(1)Auto Fan Injection Mould Trial Process

Kaihua conducts a rigorous trial molding process for every Auto Fan Injection Mould to ensure optimal performance before mass production. During the trial, we test mold flow, injection parameters, and cooling efficiency to verify stability and repeatability under high-volume conditions. Each sample part is inspected for dimensional accuracy, surface finish, and structural strength, confirming that the handle components meet durability, functional, and aesthetic requirements. This process guarantees that the mould can deliver consistent quality across different vehicle models while supporting the efficiency of large-scale automotive interior production.

(2)Product shipment and packaging photos

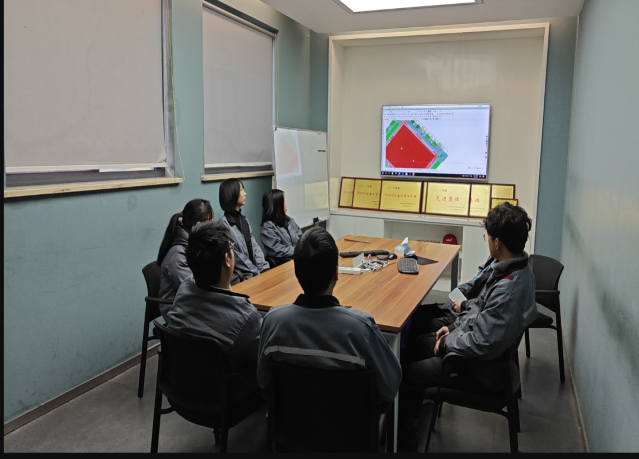

(4)Design review photos

(5) Photos of the Technical Department Meeting

(6) Certificate

To learn more about Kaihua's certificates, please click here

8.Kaihua Mould Advantage

9.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.