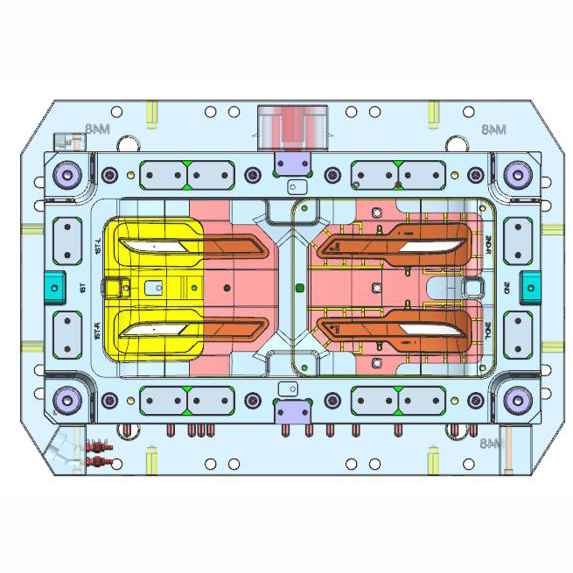

Car Lamp Injection Mould Auto Lamp Mould

1.Product Introduction

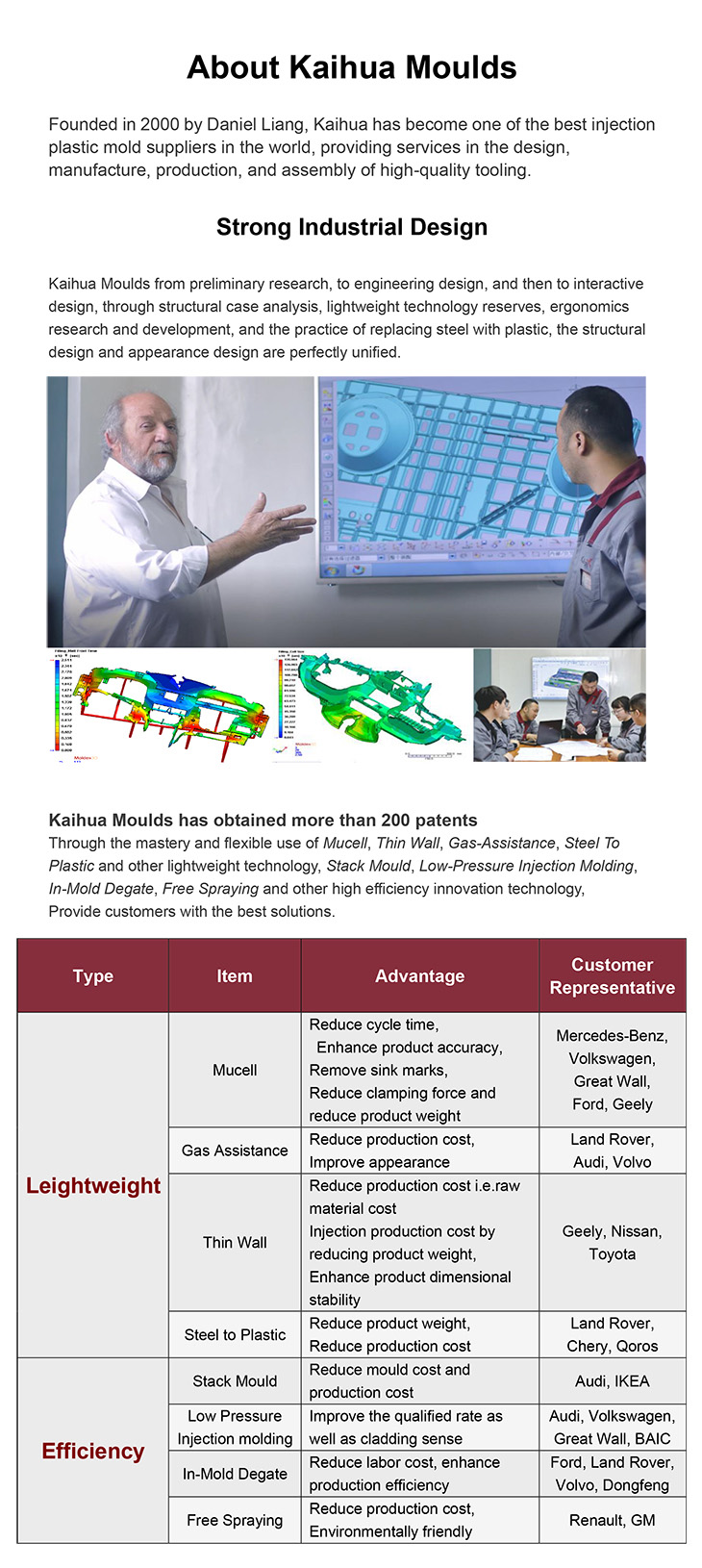

Zhejiang Kaihua Mould is a leading automotive mold maker specializing in the design and production of Auto Lamp Moulds and Car Light Moulds. With over 25 years of industry experience, Kaihua leverages 5-axis CNC machining and mirror EDM technology to achieve dimensional accuracy within ±0.001 mm, ensuring uniform light transmission and consistent optical performance for components such as light guides, lenses, and optical molds.

Kaihua has deep expertise in molding PC, PMMA, and ABS, materials widely used in automotive lighting. Its proficiency in 2K/3K multi-material co-injection allows the company to eliminate common defects such as weld lines and flow marks, producing flawless headlight molds, lamp shade molds, and front reflector molds for modern vehicles.

Operating under a rigorous IATF 16949-certified quality system, Kaihua ensures full-process control from incoming material inspection to final mold validation, delivering mass-production stability. Supported by a dedicated Automotive Lamp Division, the company offers end-to-end services including DFM analysis, mold design, precision machining, and trial optimization. Trusted by Audi, FAW-Volkswagen, and Volvo, Kaihua provides reliable lamps plastic moulds with global technical support and 48-hour response service.

In addition, Kaihua Mould's flagship solutions include the Auto Head Lamp Plastic Mold and the Front Foglight Reflector Plastic Injection Mould, both of which have earned broad recognition across the automotive tooling industry.

2.Product Display

|

Brand |

Kaihua Moulds |

|

Mold Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Standard |

HASCO, DME, MISUMI, PUNCH, or your requirement |

|

Product Material |

PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

|

Runner |

Cold/Hot Runner |

|

Hot Runner Brand |

YUDO/Synventive/Mold-Masters/ HRS/ INCOE/ Customized |

|

Mold Cavity |

Single Cavity / Family Molds / Multi Cavity |

|

Production Capacity |

4000 Sets/Year |

3.Product Display

4.Product feature and application

(1) Product feature

Zhejiang Kaihua Mould specializes in automotive lamp injection molds, supported by a dedicated Automotive Lamp Division and over 25 years of technical expertise. Equipped with 5-axis CNC machining centers and mirror EDM machines, Kaihua masters key processes such as 2K/3K multi-material co-injection and in-mold cutting, achieving optical-grade accuracy to ensure uniform light transmission across lamp components.

Through its modular mold design system, Kaihua has successfully reduced mold delivery lead time to 70% of the industry average, providing high-efficiency mass-production mold solutions for renowned brands including Audi and Volvo.

The company operates a comprehensive quality management system, featuring 12 five-axis CNC machines, 7 high-precision EDM units, and a complete range of inspection equipment. From raw material inspection to final mold validation, every process follows stringent quality control standards. Backed by a global supply chain and overseas service network, Kaihua ensures 24-hour rapid response, delivering reliable technical support and after-sales service worldwide.

Contact us to discuss how our proven capabilities can enhance your thermal management systems.

(2) Product application

● Adaptive Cooling for Efficient Production

Kaihua Auto Lamp Moulds feature optimized cooling channels tailored to each lamp component, from light guides to tail lamp housings. This ensures uniform heat dissipation, reducing cycle times and preserving the optical and mechanical quality of headlight molds and lamp shade molds during high-volume production.

● Modular Design for Rapid Iteration

With standardized core modules like ejection systems and gating units, Car Light Moulds can quickly adapt to minor design changes, such as lens curvature or reflector angles, shortening prototype lead times and accelerating product development cycles.

● Enhanced Wear Resistance

Critical zones of Optical Molds receive advanced surface treatments (e.g., PVD coating) to increase scratch and corrosion resistance. This extends mold lifespan, reduces friction, and ensures stable performance over 500,000+ shots.

● Sustainable Manufacturing

Designed for low-energy injection and compatibility recycled PC/PMMA, Lamps Plastic Moulds minimize material waste and scrap, supporting automakers' sustainability goals while maintaining high-quality standards.

● Smart Monitoring Ready

Pre-equipped with sensor ports, Automotive Moulds allow IIoT integration for real-time monitoring of pressure, temperature, and cycle deviations, improving production control and reducing post-mold inspection costs.

5.Kaihua Service

● Global Technical Network

With 15 international technical centers spanning Europe,Americas and Asia,we provide localized engineering support and rapid response services.

● Expert Engineering Team

Our 180-member design team and 350 certified technicians deliver professional DFM analysis and continuous technical guidance.Each project is assigned a dedicated project manager who maintains transparent communication and provides regular progress updates.

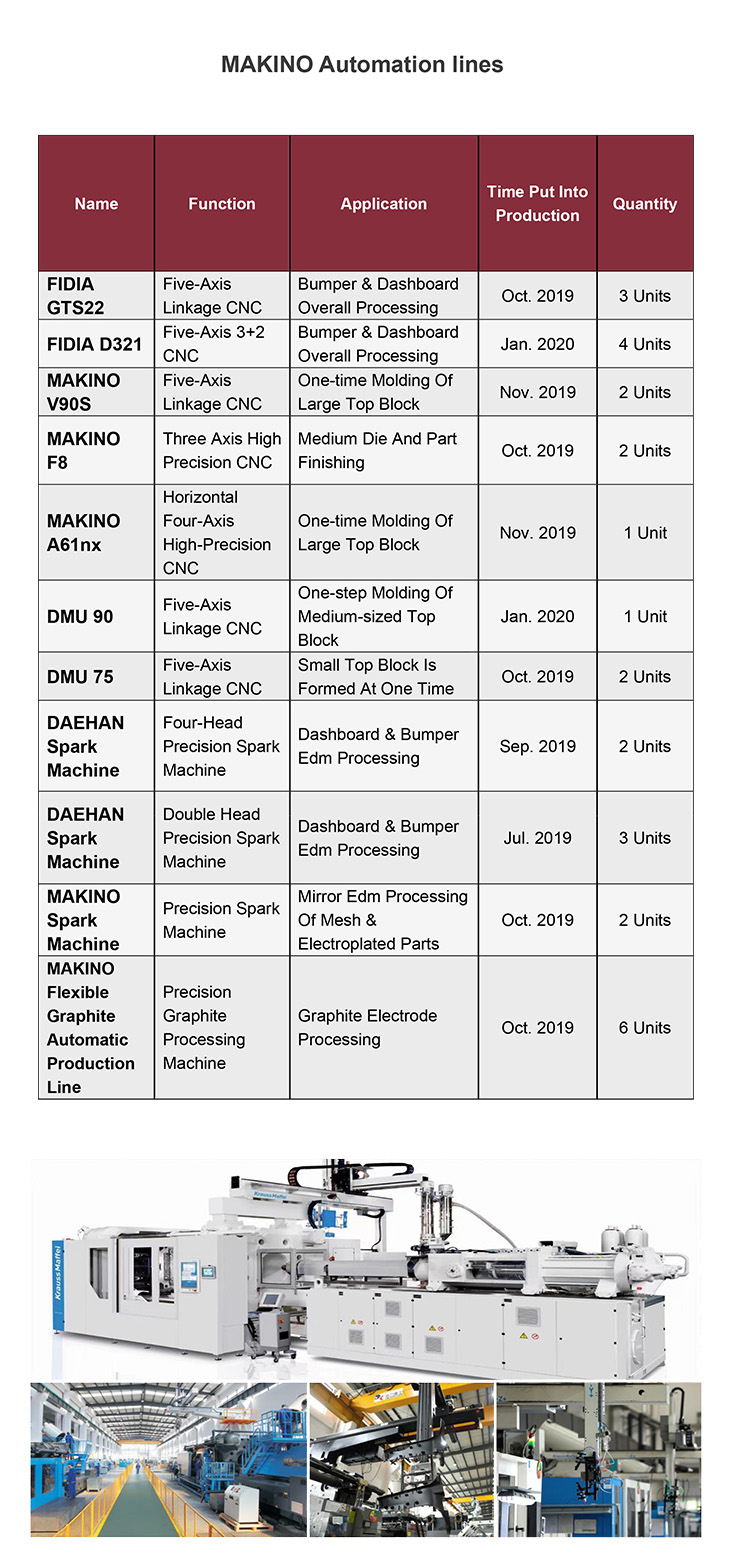

● Advanced Manufacturing Facilities

Our smart factory integrates MAKINO graphite machining centers and automated lifter systems within fully automated lines, supporting autonomous, round-the-clock operations for uninterrupted production.The 251,300m²manufacturing base is equipped with high-precision inspection equipment from Germany WENZEL and Sweden HEXAGON.

● Proactive Service System

We implement KMS lean management to eliminate 9 types of production wastes,ensuring optimal efficiency.Our service includes comprehensive operator training,efficient spare parts supply,and regular performance follow-ups to maximize your production uptime.

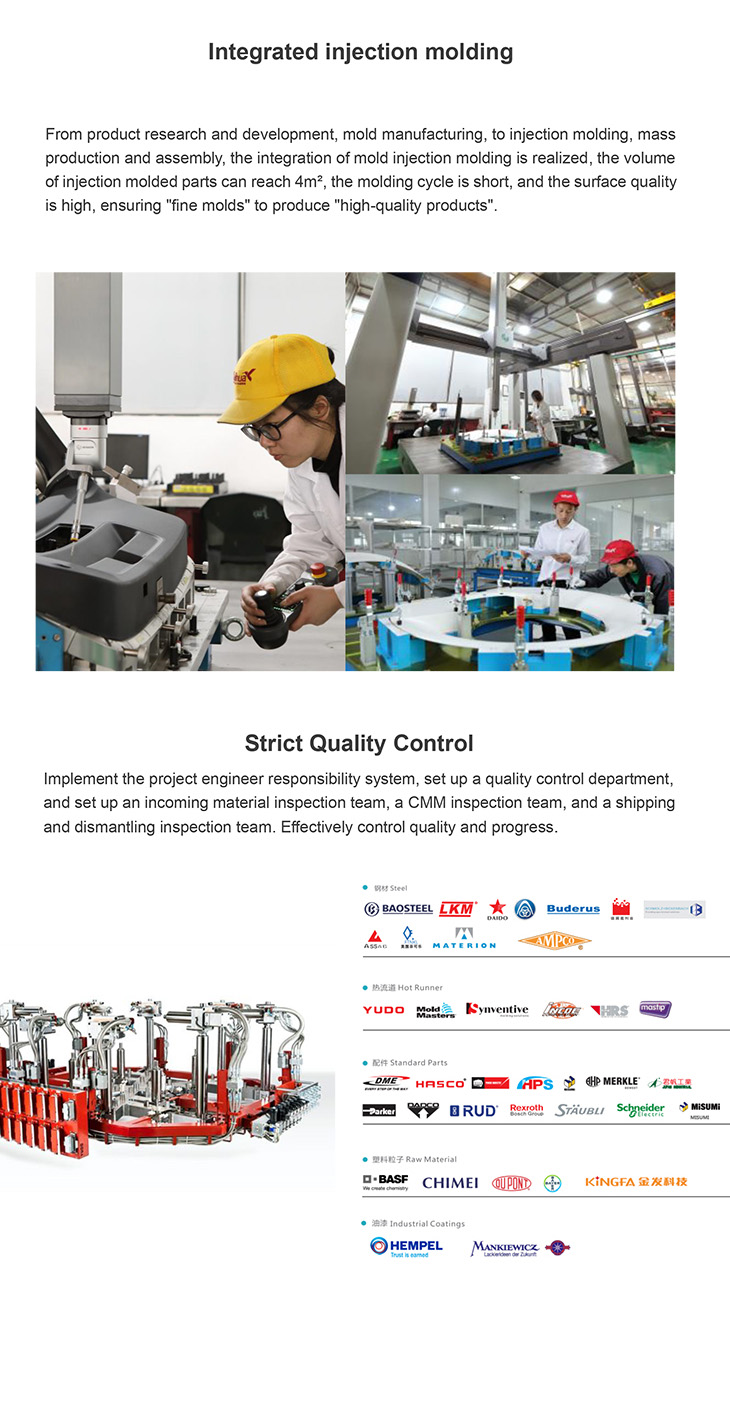

● Total Quality Assurance

Backed by ISO 9001:2015 certification and 44 quality engineers,we implement rigorous quality control throughout the manufacturing process.Each project undergoes multiple inspection checkpoints and comprehensive testing before delivery.

● Lifetime Partnership Commitment

Beyond mold delivery,we provide lifetime technical support and maintenance services.Our global spare parts network and regular maintenance recommendations help extend mold service life and optimize your long-term production costs.

With 25 years of automotive mold expertise and continuous improvement through KMS,we are committed to being your reliable manufacturing partner for sustainable production success.Click to learn more about how Kaihua supports you after delivery.

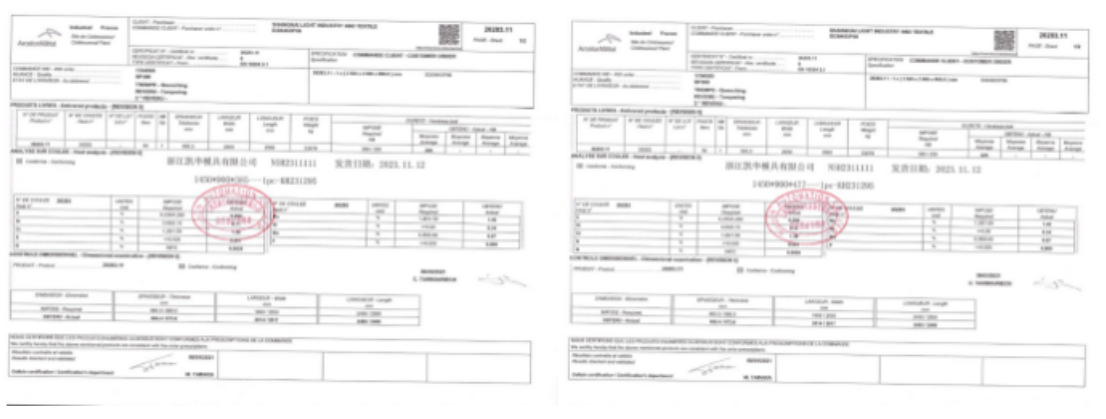

6.Product qualification

(1)Car Lamp Injection Mould Trial Process

Kaihua conducts a rigorous trial molding process for every Auto Lamp Injection Mould to ensure optimal performance before mass production. During the trial, we test mold flow, injection parameters, and cooling efficiency to verify stability and repeatability under high-volume conditions. Each sample part is inspected for dimensional accuracy, surface finish, and structural strength, confirming that the handle components meet durability, functional, and aesthetic requirements. This process guarantees that the mould can deliver consistent quality across different vehicle models while supporting the efficiency of large-scale automotive interior production.

(2)Product shipment and packaging photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here