Car Rear Bumper of Plastic Injection Mold

1. Product Introduction

Kaihua Mould delivers high-performance Car Rear Bumper Injection Mold solutions that set the standard for precision engineering and long-lasting durability. Our Plastic Injection Mold for Car Rear Bumper is designed for a perfect fit and smooth finish, making it ideal for OEM manufacturing and custom bumper mould projects.

By using advanced techniques such as gas-assisted injection moulding, low-pressure molding, and MuCell micro-foaming, each Automotive Rear Bumper Injection Mold produces lightweight yet impact-resistant bumpers. This improves vehicle safety, fuel efficiency, and overall visual appeal without compromising strength.

Whether you need high-volume injection mould production or tailor-made rear bumper plastic injection mold solutions, Kaihua offers fast turnaround, competitive pricing, and consistent quality—making us a trusted partner for leading car brands worldwide.

Besides, Kaihua’s Car Door Panel Injection Mould with Gas Assistance Technology and Car Led Combination Tail Light Plastic Injection Molding have also received widespread acclaim within the industry.

2. Case Product Parameters

|

Product Name |

Rear bumper |

|

Plastic material |

PP+EPDM-T20 |

|

Injection molding machine tonnage |

2000 |

|

Number of mold cavities |

1*1 |

|

Grain or electroplate |

spray painting |

|

Automatic demolding requirements |

Robot |

3. Production details

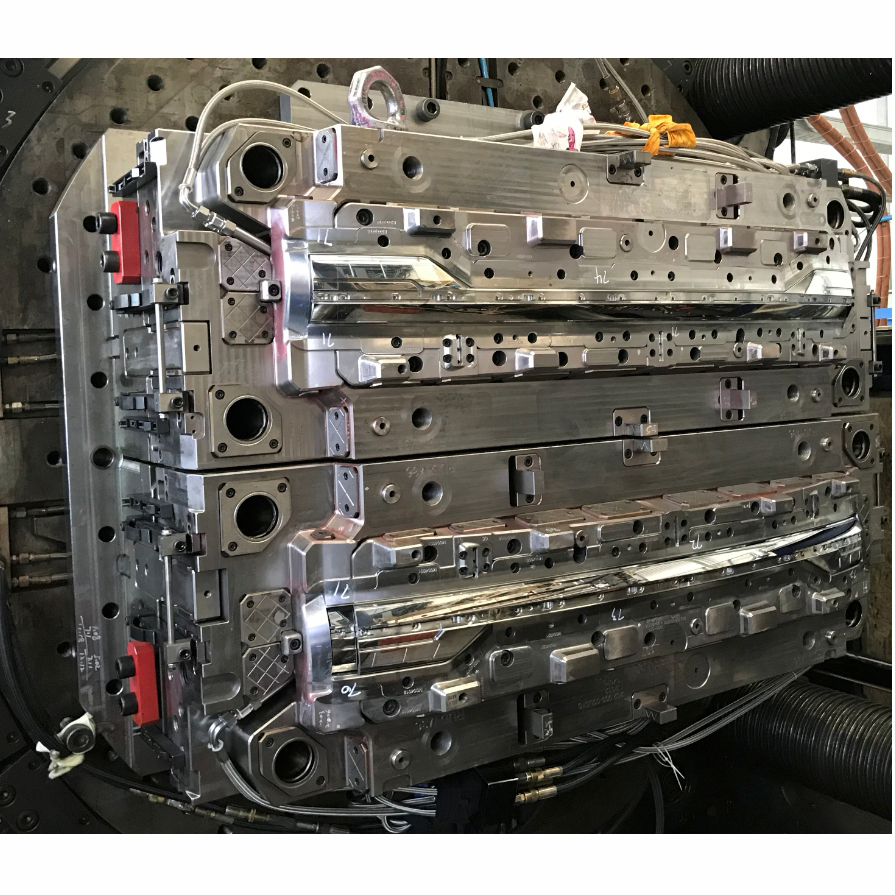

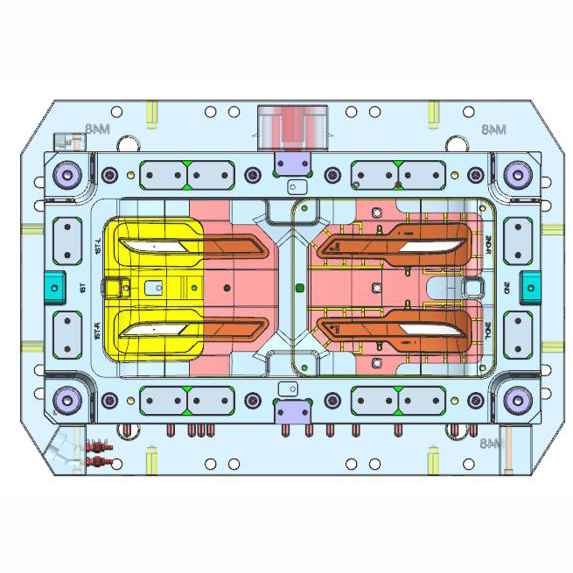

4.Production details

5.Product feature and application

(1)Product Feature

Kaihua Car Rear Bumper Injection Mold – Designed for precision fit, durability, and style.

●Impact-Resistant – Built from high-grade mold steel, Kaihua’s Car Rear Bumper Injection Mold delivers exceptional durability, supporting 0.5-1 million of production cycles without deformation.

●Perfect Fit – CNC precision machining ensures accurate dimensions, tight parting lines, and hidden weld lines for a seamless bumper finish.

●Customizable Design – Supports advanced molding technologies such as gas-assisted injection, micro-foaming, and reduced-pressure molding for lightweight yet strong rear bumpers.

●Cost-Effective – Optimized cooling channel design and robust mold structure reduce cycle times, increasing efficiency while maintaining stable quality.

●High Surface Quality – The Plastic Injection Mould for Car Rear Bumper achieves a smooth, paint-ready surface directly from the mold, reducing post-processing costs.

●Easy Maintenance – Modular mold components allow quick replacement and minimal downtime, extending service life.

●Global Standard Compliance – Designed to meet OEM and international standards, making the bumper mould ideal for both domestic and export markets.

●Long-Term Reliability – Engineered to perform consistently under high-volume production, ensuring quality and repeatability for years.

(2)Application

●OEM Manufacturing – Trusted by leading car brands, our Automotive Rear Bumper Injection Mold ensures precision fit and long-lasting performance for large-scale production.

●Aftermarket Replacement – Perfect for producing rear bumpers that match original factory specifications, maintaining safety, style, and aerodynamics after collision repairs.

●Global Market Supply – Engineered to meet international standards, our Plastic Injection Mould for Car Rear Bumper supports global exports with consistent quality and compliance.

6.Prodect qualification

(1)Product shipment and packaging photos

●Mold Preparation: Securely close the mold to ensure it is properly aligned and ready for injection.

●Material Loading: Introduce dried plastic pellets into the hopper of the injection molding machine.

●Melting Phase: Heat the injection unit to melt the plastic pellets uniformly.

●Injection Phase: Inject the molten plastic into the mold cavity using a precision injection system.

●Pressure Maintenance: Apply consistent pressure to ensure the mold cavity is fully filled and maintains its shape during the filling process.

●Cooling Phase: Allow the injected plastic to cool and solidify within the mold, taking on the desired shape.

●Ejection: Carefully open the mold and eject the finished plastic product.

(2)Product shipment and packaging photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

8.FAQ