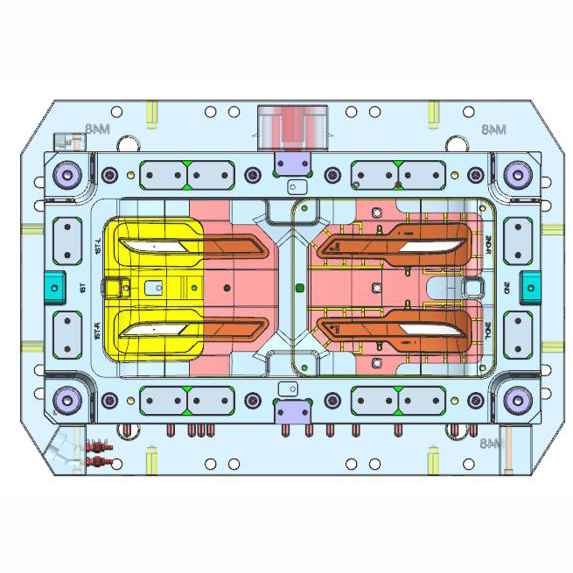

Center console mold

1. Product Introduction

Kaihua Mold is at the forefront of innovation in automotive center console molds, delivering customized solutions backed by over 20 years of industry expertise. We understand that a car’s dashboard is not just a functional control hub but a critical element in shaping the in-car experience. By integrating cutting-edge technology and precision craftsmanship, our molds accurately replicate complex console shapes, button layouts, and decorative textures, ensuring flawless reproduction of even the finest structural and surface details.

Customization is at the heart of our service. Kaihua experienced team works closely with automakers to tailor molds to different vehicle models and brand design philosophies—meticulously selecting materials, optimizing structures, and preparing for high-volume production. Whether meeting the premium finish demands of luxury cars or balancing cost and practicality for budget-friendly models, Kaihua Mold delivers precise solutions.

Partnering with Kaihua means choosing an efficient, professional, and innovative ally. We are committed to elevating automotive interior manufacturing, delivering high-performance molds for dashboard production. Additionally, our extensive experience in home appliance molds—such as EV Battery Case Mold and Bumper of Car Products—brings added expertise to automotive mold manufacturing, ensuring every step from design to delivery helps automakers achieve superior quality.

2. Case Product Parameters

| Product Name | Center Console Mold |

| Plastic material | ABS/PP/Customz |

| Mold size | 2500*1200*1000 |

| Mold weight (t) | 6.3 |

| Molding cycle | Customz |

| Hot runner | YUDO/HASCO/Synventive/Customz |

| Product wall thickness (mm) | 2.5-3.5 |

| Mold shrinkage | Customz |

| Product weight (t) | 4.7 |

| Product size | 2350X1067X937 |

| Application | Customz |

| Clamping type | Customz |

| Grain or electroplate | Customz |

3. Product Display

(1)Water Interface

(2)Hot runner socket

4.Product feature and application

(1)Features:

·Precision Craftsmanship: Kaihua's automotive center console molds masterfully transform complex designs into high-precision products, accurately replicating panel curves, button holes and decorative textures to ensure component consistency and premium quality output.

·Structural Performance Optimization: Kaihua's molds balance lightweight design with structural integrity, featuring reinforced load-bearing components to prevent deformation while optimizing snap-fit connections for superior vibration resistance in automotive environments.

·Cost-Effective Production: Kaihua optimizes mold structures and streamlines processes to reduce material waste and cycle times, while maintaining premium surface finishes (including matte/gloss treatments) to deliver affordable mass production solutions.

·Precision Dimensional Control: Kaihua maintains strict mold tolerances to ensure seamless integration with automotive electronics and interior components, enhancing assembly efficiency and cabin compatibility.

·Eco-Conscious Design: With a strong commitment to environmental protection, we utilize recyclable materials and energy-efficient processes to meet production demands while reducing resource consumption, supporting sustainable development in the industry.

(2)Applications:

·Residential Vehicle Solutions: Kaihua's molds for sedans and SUVs combine functionality with aesthetic appeal, producing integrated panels with storage compartments and cup holders. Custom surface finishes including matte and woodgrain textures perfectly complement home-style interior designs.

·Commercial Vehicle Solutions: Kaihua's heavy-duty molds for trucks and buses feature reinforced structures to support additional device interfaces, with vibration-resistant designs that ensure long-term durability under demanding road conditions.

·Custom Development Solutions: Kaihua enables automotive upgrades through precision molds for integrated touchscreen housings, optimized control layouts, and EV smart panels, utilizing dimensional accuracy and process innovation to enhance product differentiation.

5.Prodect qualification

(1)Production process

· Closing the mold: Close the mold to ensure it is in place.

· Feeding: Add the dried plastic pellets into the hopper of the injection molding machine.

· Melting: Heating the injection molding machine to melt the plastic particles.

· Injection: Molten plastic is injected into a mold through an injection device.

· Pressure holding: Maintain a certain pressure in the mold to fully fill the mold with plastic.

· Cooling: Cooling and solidifying in the mold to shape the plastic.

· Demoulding: Open the mold and remove the plastic product.

(2)Images of product dispatch and packaging

(3)Technical team

| Responsibilities of project members | Main responsibilities |

| project manager | Supervise the entire project planning and control the quality, time, and cost of the project |

| Quality Manager | Responsible for project quality matters |

| salesman | Responsible for project business and logistics work |

| Design team leader | Responsible for reviewing and guiding product analysis and design, as well as mold structure design |

| Process Supervisor | Responsible for the development of mold production processes and production management |

| Mold Supervisor | Responsible for the research and assembly of molds, as well as guidance on mold technology |

(4)Design review photos

(5)Photos of the Technical Department Meeting

(6)Certificate

7.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua's advantages,experience our professional strength and quality assurance!

8.FAQ