China wholesale Automotive Plastic Injection Molding moulds Supplier – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA

China wholesale Automotive Plastic Injection Molding moulds Supplier – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA Detail:

1.Product Introduction

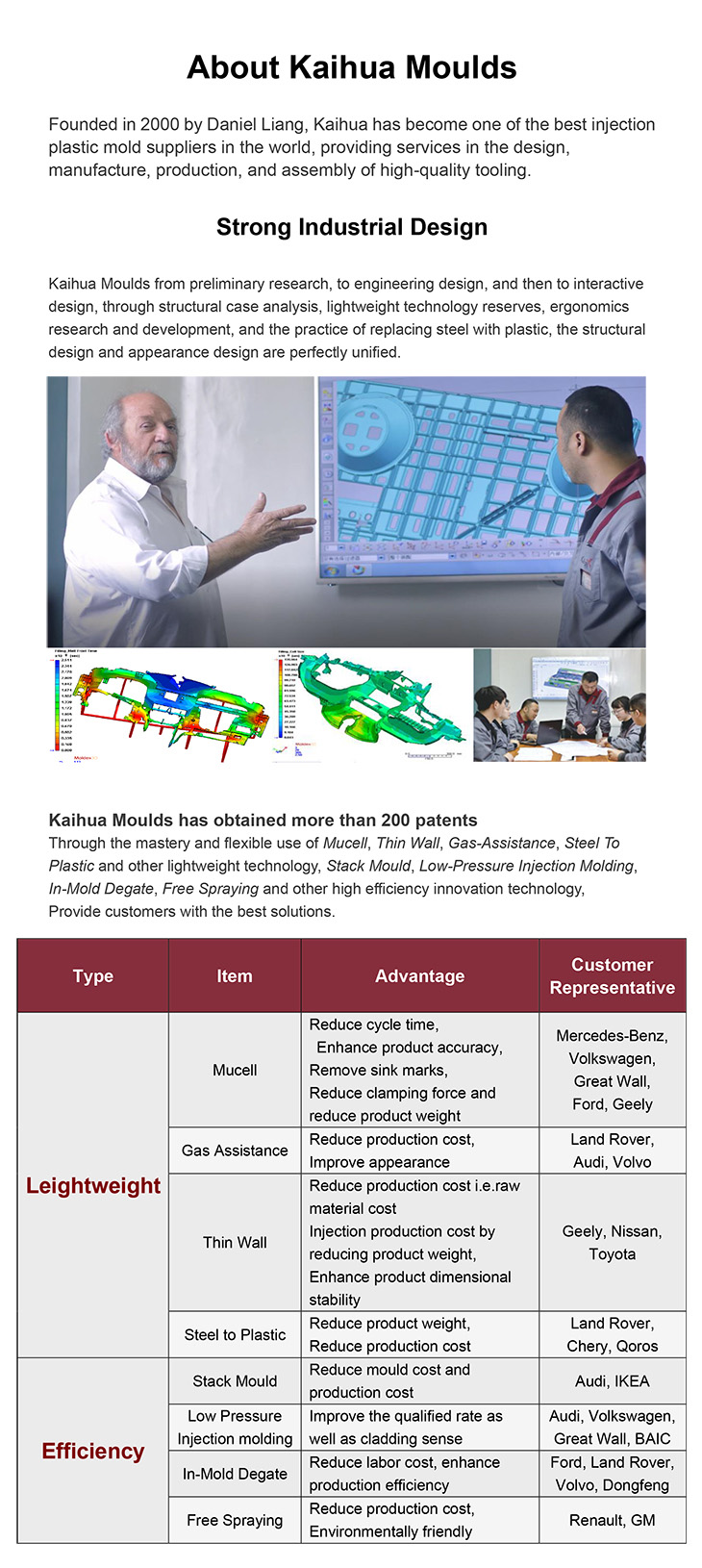

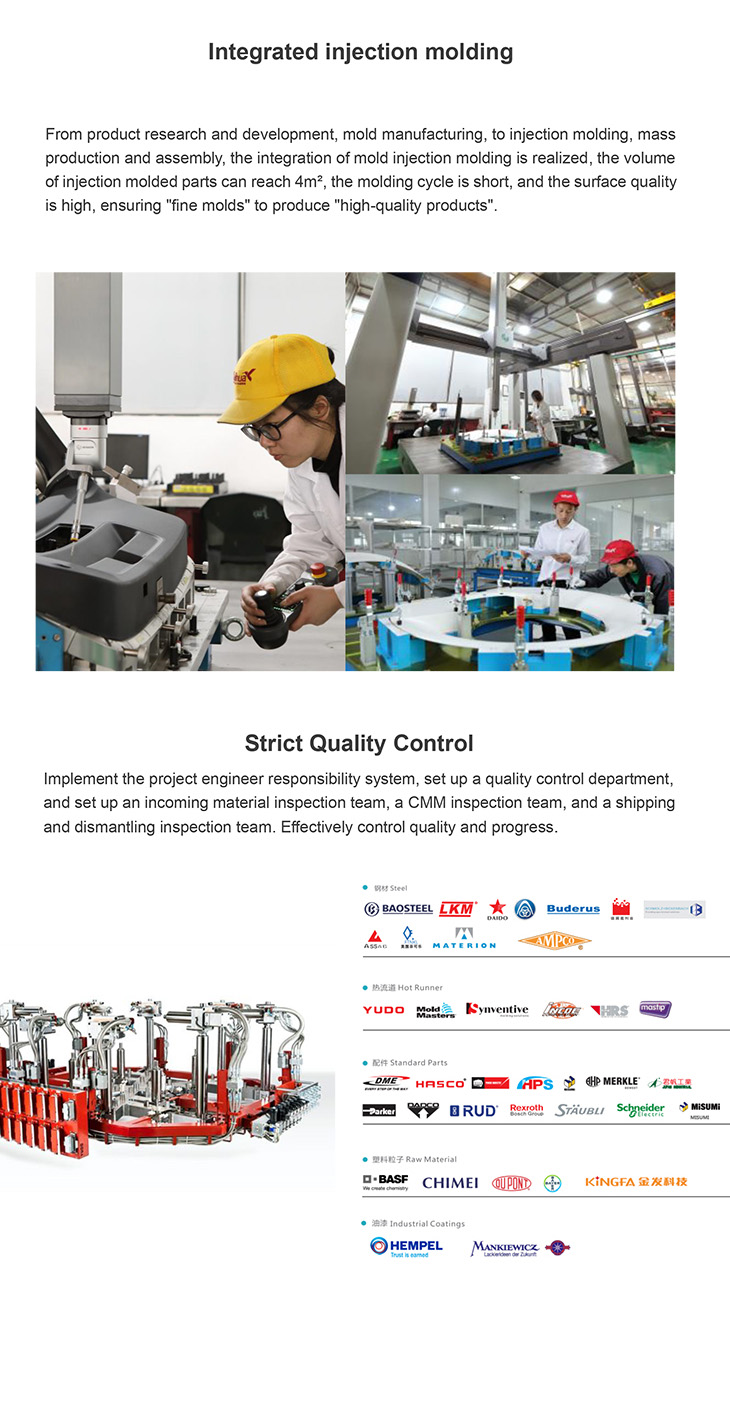

We can provide customers with the best solutions for Automotive Plastic Injection Molding for Internal Parting Car Bumper.

Kaihua Service include: Product Design, Mold Design, Mold Making, Products Research & Development & Produce, Provide Processing Injection Molding For Tier 1.

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | P20, 718, 8407, Nak80, H13, S136, DIN 1.2738, DINt |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc, or your requirement |

| Shaping Mode: | Plastic Injection Mould |

| Mold Cavity | Single Cavity / Family Molds / Multi Cavity |

| Quote | According to Samples, Drawing and Specific Require |

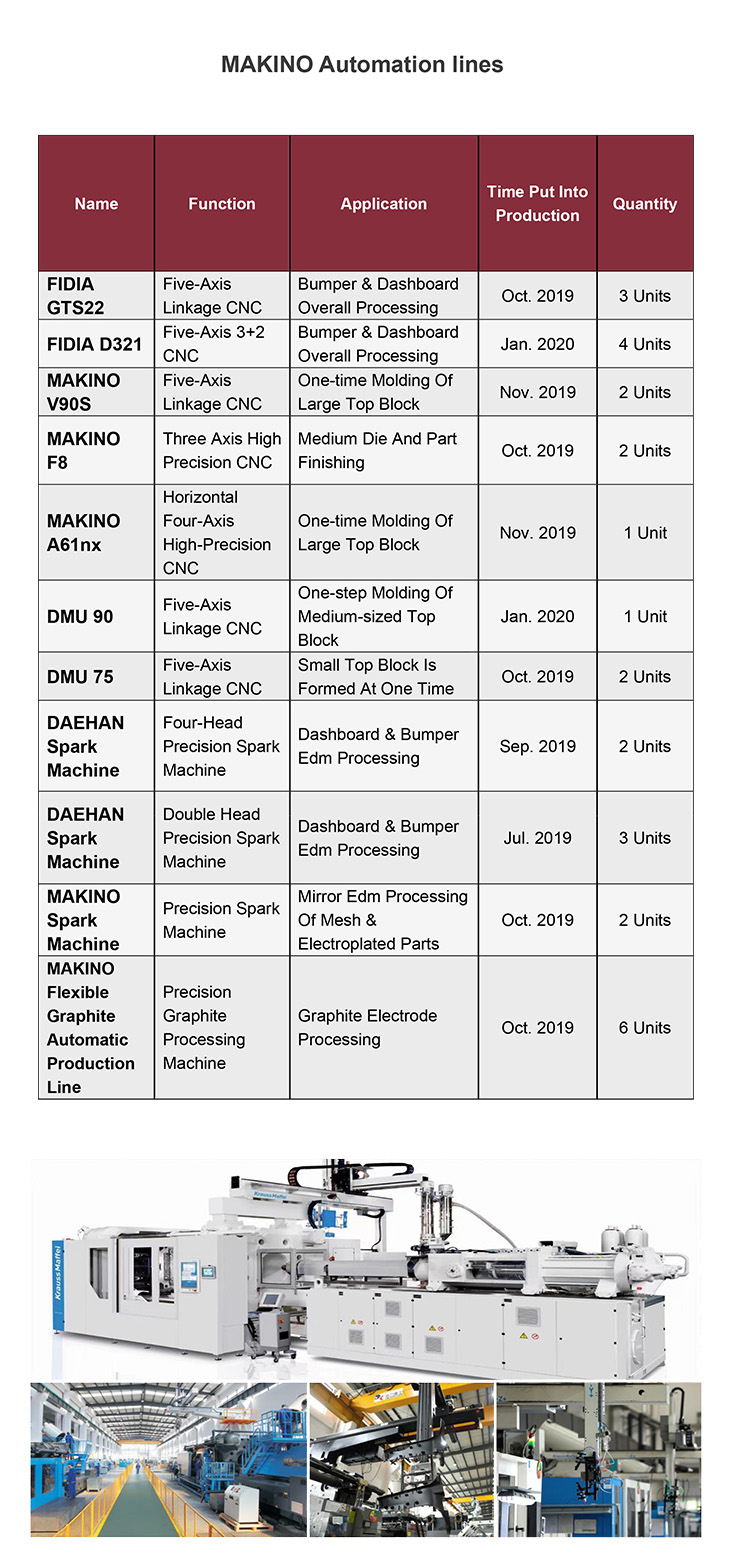

| Production Capacity | 2400 Sets/Year |

| Design Software | CATIA, UG |

3.Product Feature and Application

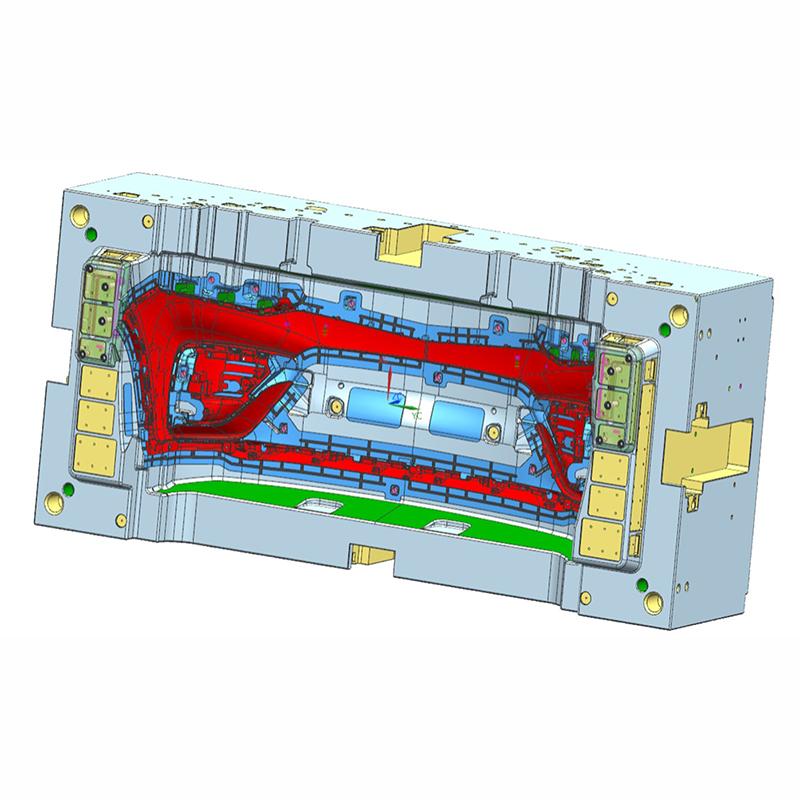

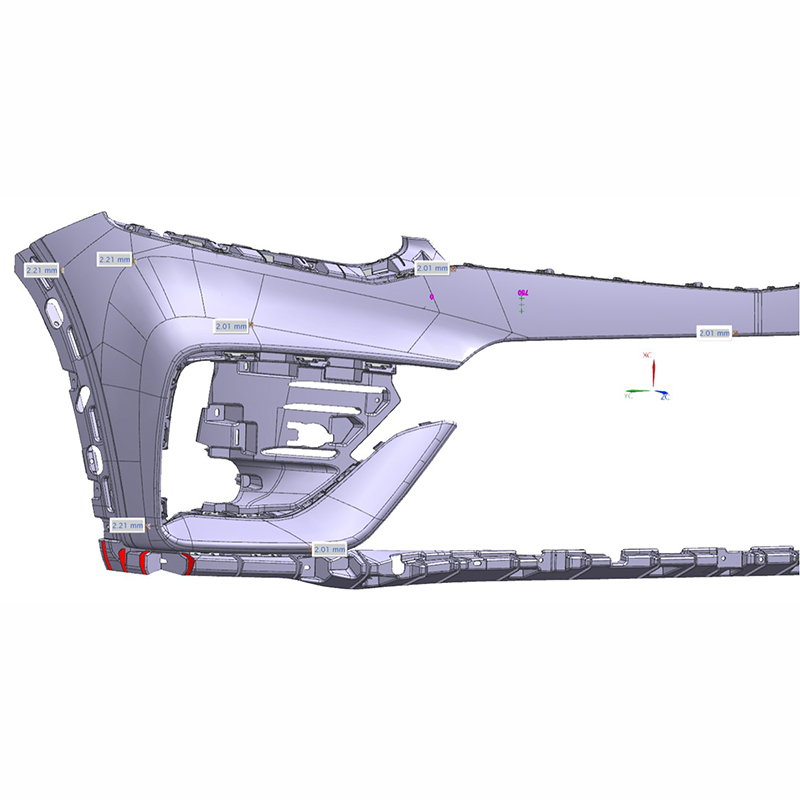

Technical Features : Internal Parting Car Bumper

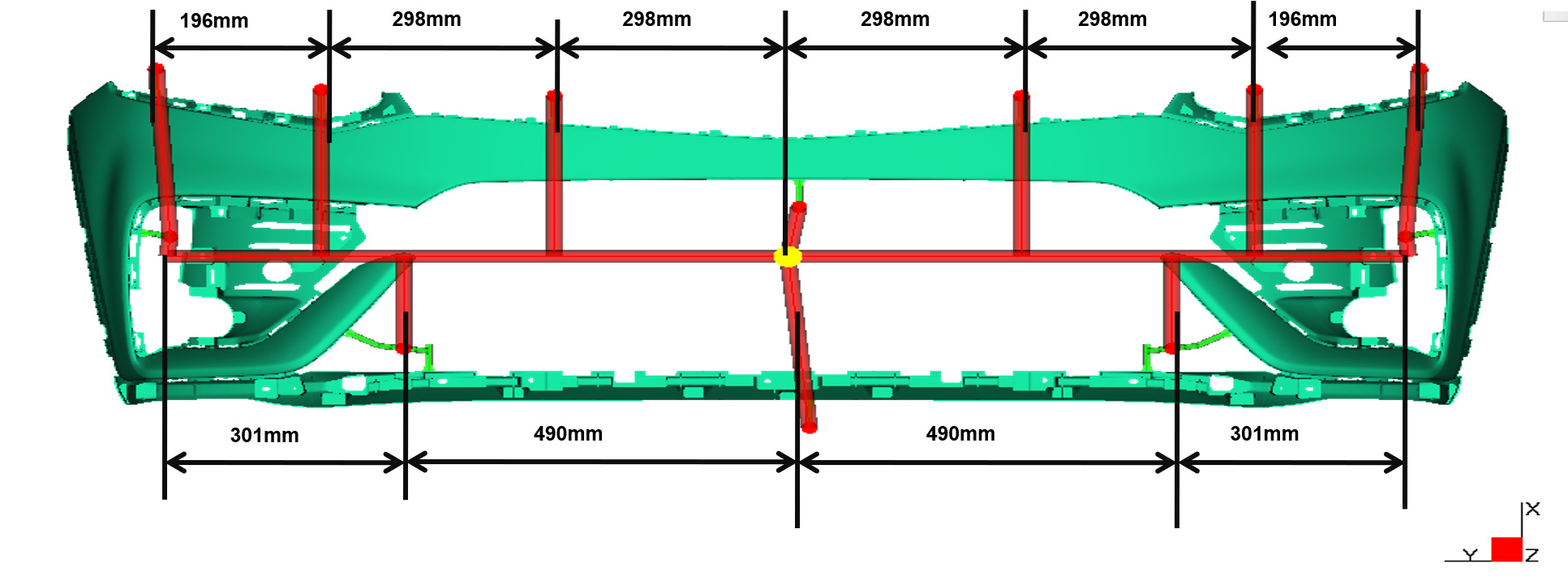

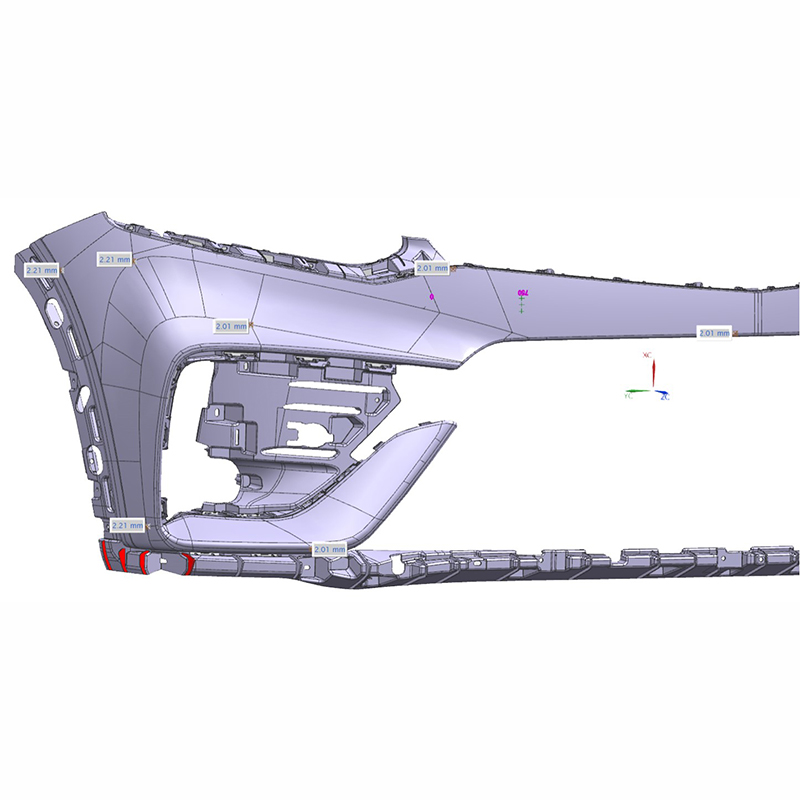

2.Unequal thin-wall design

The middle area is 2.0mm, and the ends on both sides are thickened gradually to 2.2mm.

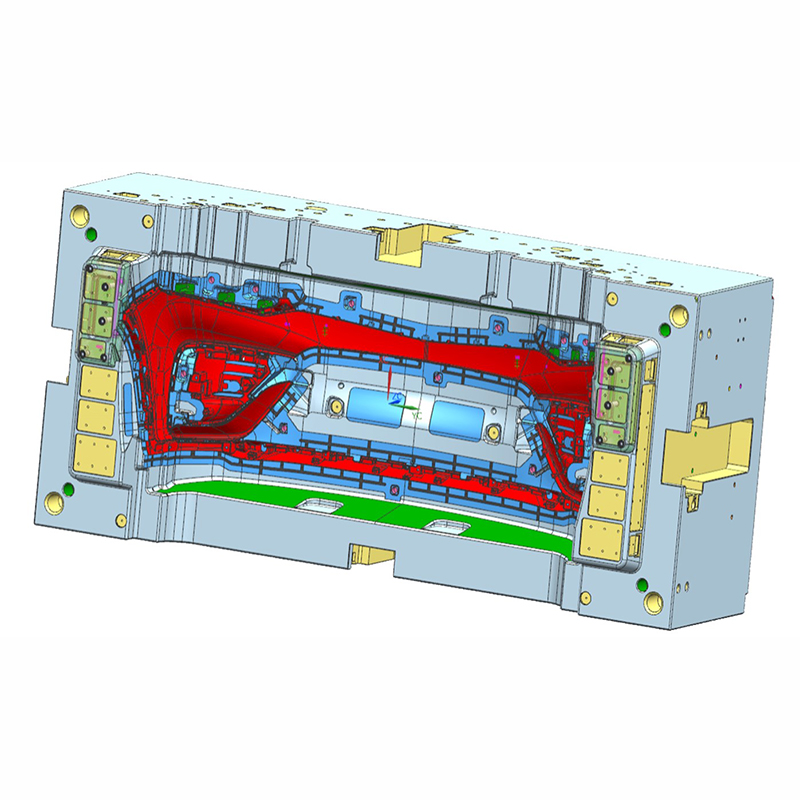

2.Hot runner scheme

2.Hot runner scheme

The hot runner scheme using Synventive Sequence valve gate 12 drops.

3.Simulated fill time (About 7.1s)

3.Simulated fill time (About 7.1s)

4.Cavity parting technology

4.Cavity parting technology

The internal parting bumper is perfectly injection-molded at one time through the secondary track change track control technology, therefor ensuring the appearance quality of the bumper and saving the processing procedures and processing costs of plastic parts.

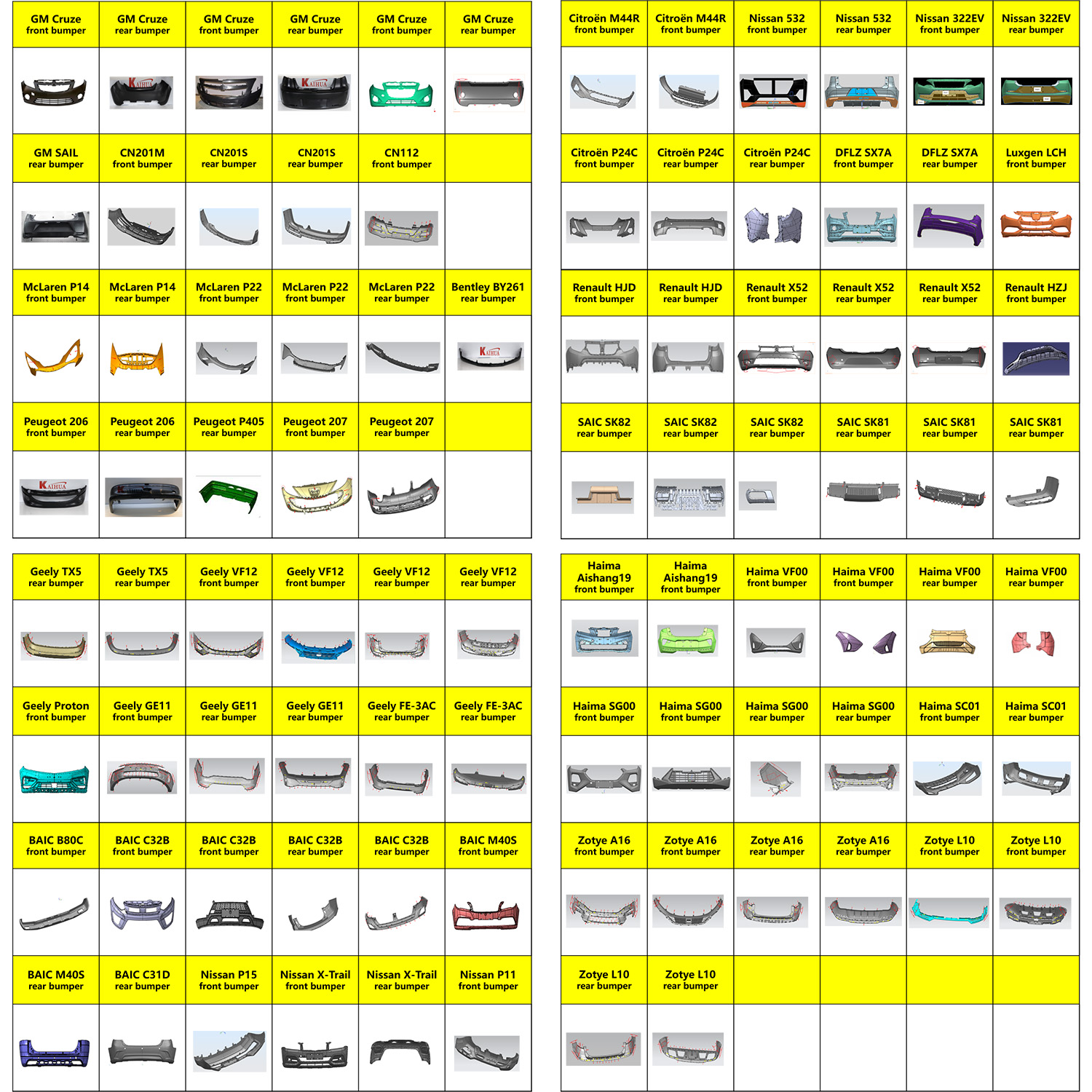

4. Cooperation Cases

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for China wholesale Automotive Plastic Injection Molding moulds Supplier – Internal Parting Car Bumper Mould with Thin wall Design – KAIHUA , The product will supply to all over the world, such as: Greek, Jamaica, Slovenia, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.