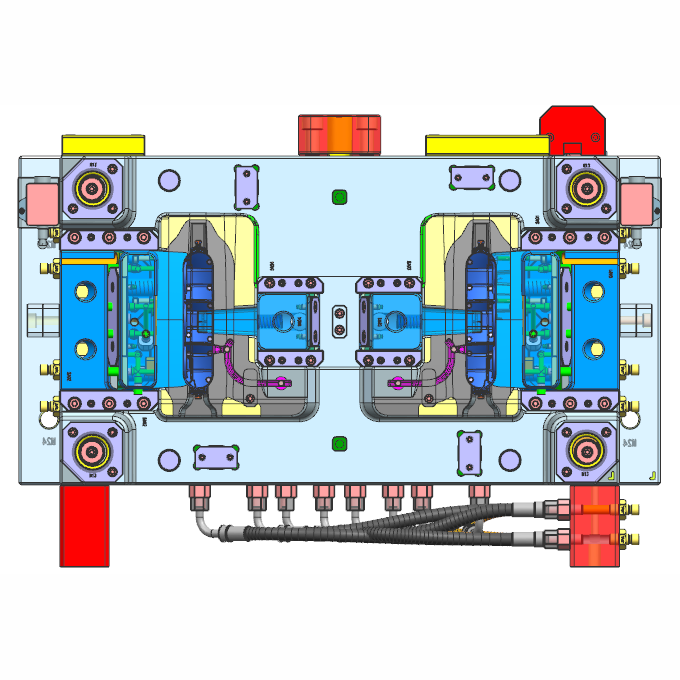

China wholesale Small Metal Parts Stamping Moulds Supplier – Front Foglight Reflector Plastic Injection Mould – KAIHUA

China wholesale Small Metal Parts Stamping Moulds Supplier – Front Foglight Reflector Plastic Injection Mould – KAIHUA Detail:

Product Introduction

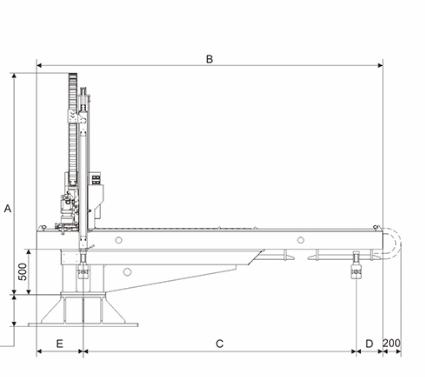

This Servo Driven Robot is driven by imported AC servo motors. The arms ues the light-weight and high-rigid aluminum alloy structure beams, which can meet the requirements of fast fetching, smooth and unhindered action, high efficiency, low vibration and long sevice life. The robot can realize all kinds of special actions, such as arrangement, stacking, quality inspection and embedding, etc.

Product Parameter (Specification)

| Power Source | AC220V±10% 50/60 HZ |

| Type | Telescopic Type |

| Suitable I.M.M. | 1300T-2400T |

| Vertical | 2000mm |

| Crosswise | 300-1400mm |

| Transverse | 2500-3000mm |

| Gripper Angle | 90° |

| Max Load(includes gripper) | 15kg |

| Min take out time | 3.0 sec |

| Method | X,Y,Z AC Servo motor |

| Working Air Pressure | 0.5-0.8Mpa |

| Air Consumption | 2.0NL/Cycle |

| Max Net Weight | 900kg |

Details

Advantages

√ Aesthetic

This Five Axes Servo Driven Robot adopts European streamline design, whose transverse beam, guide beam and upper and lower arms are standard profiles, leading to compact structure and beautiful appearance.

√Safety Position limit sensors and blocks effectively prevent mechanical and electrical malfunctions. Control board is designed to CE EMC test with short circuit and noise proof functions. √Humanization

Servo driven axis provides the possibility of multi points for positioning products and sprues.

√Convenience

Control hardware fixtures are designed with flyer structure which provides benefit to maintenance. Cable drag chains help with cable management and ease for maintenance.

√Intelligence

Real time remote monitoring and telediagnosis assist better equipment management. USB port allows fast data updating, saving and loading.

● High Quality (Product &Mould) ● On-time Delivery (Sample, Mould) ● Cost Control (Direct Cost, Indirect Cost) ● Best Service (Customers, Employee, Other Department, Supplier) ● Form— ISO9001:2008 Quality management systems ● Process—Project Management ● ERP management system ● Standardization—Performance Management

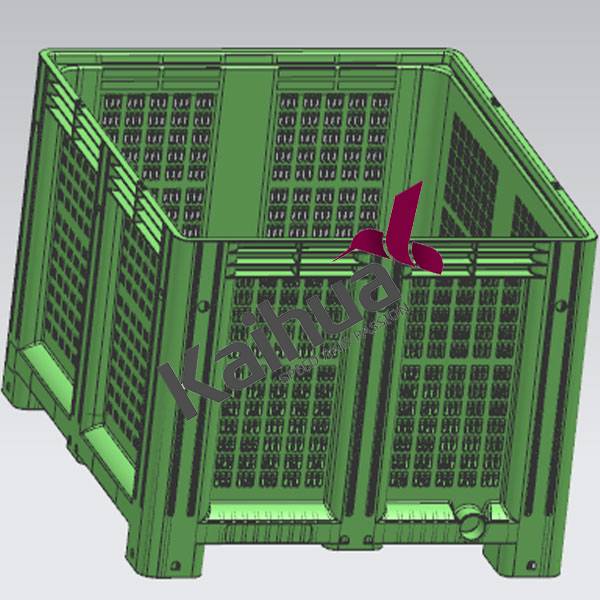

Product Introduction

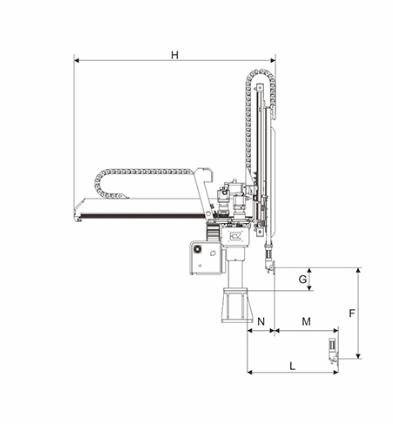

This Five Axes Servo Driven Robot is divided into single cut and double cut for customers to choose, and it highly matches to two-plate mold, third-plate or hot runner mold. The robot can realize all kinds of special actions, such as arrangement, stacking, quality inspection and embedding, etc.

Product Parameter (Specification)

| Power Source | AC220V±10V 50/60 HZ |

| Drive System | Customized |

| Swivel | 90°Fixed Pneumatic |

| Standard | EUROMAP12, SPI, EUROMAP67 |

| Core Component | Motor |

| Video outgoing-inspection | Provided |

Details

Advantages

√ Aesthetic

This Five Axes Servo Driven Robot adopts European streamline design, whose transverse beam, guide beam and upper and lowaer arms are standard profiles, leading to compact structure and beautiful appearance.

√Safety Position limit sensors and blocks effectively prevent mechanical and electrical malfunctions. Control board is designed to CE EMC test with short circuit and noise proof functions. √Humanization

Servo driven axis provides the possibility of multi points for positioning products and sprues.

√Convenience

Control hardware fixtures are designed with flyer structure which provides benefit to maintenance. Cable drag chains help with cable management and ease for maintenance.

√Intelligence

Real time remote monitoring and telediagnosis assist better equipment management. USB port allows fast data updating, saving and loading.

● High Quality (Product &Mould) ● On-time Delivery (Sample, Mould) ● Cost Control (Direct Cost, Indirect Cost) ● Best Service (Customers, Employee, Other Department, Supplier) ● Form— ISO9001:2008 Quality management systems ● Process—Project Management ● ERP management system ● Standardization—Performance Management

Product detail pictures:

Related Product Guide:

No matter new customer or old customer, We believe in long term and trusted relationship for China wholesale Small Metal Parts Stamping Moulds Supplier – Front Foglight Reflector Plastic Injection Mould – KAIHUA , The product will supply to all over the world, such as: Australia, Cologne, New Delhi, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!