Clear Chair Injection Mold of Outdoor Furniture

1. Product Introduction

Kaihua Clear Chair Injection Molds, engineered by the industry-experienced Kaihua Mold, are crafted from premium mold steel known for its exceptional strength and toughness. These molds ensure smooth mold opening/closing operations during daily production while offering easy maintenance - effectively reducing operational, handling, and upkeep costs. With outstanding wear resistance and corrosion protection, Kaihua mold maintain superior performance whether undergoing high-frequency production cycles or extended storage periods, delivering significantly longer service life than comparable products.

The design features a streamlined yet rational structure with diverse customization options to meet various production requirements. From compact molds compatible with small injection machines to large-scale production molds, each solution delivers precise compatibility. Incorporating advanced integrated molding technology with meticulous craftsmanship, these molds produce tightly fitted components with smooth surfaces, guaranteeing consistently stable clear chair quality with refined detailing.

Kaihua Clear Chair Injection Molds perfectly combine high-efficiency production with premium output quality, representing a thoroughly reliable mold solution for manufacturers.

2.Case Product Parameters

|

Product Name |

Clear chair |

|

Plastic material |

Modified PCT |

|

Product weight (g) |

4400 |

|

Product size |

673X536X498 |

|

Product wall thickness(mm) |

7.5 |

|

Mold weight(t) |

5.275 |

|

Mold size |

1000*850*930 |

|

Injection molding machine tonnage |

1200 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

Mirror-Finish Polishing |

|

Automatic demolding requirements |

Robot |

3. Details

4.Product feature and application

(1)Product feature

● High-Precision Structure: Utilizing advanced precision machining technology, our molds achieve exceptional closing accuracy during operation, ensuring perfect alignment of chair dimensions, curvatures, and seam connections. This guarantees consistent dimensional stability and flawless uniformity in every transparent finished product.

● Durable Materials: Manufactured from premium specialty steel or aluminum alloy, our molds undergo advanced heat treatment processes to enhance hardness and wear resistance. This enables them to withstand prolonged high-pressure injection molding impacts and abrasion, significantly extending mold service life.

● Intelligent Parting Line Design: Utilizing advanced mold flow analysis technology, we optimize parting line configurations to ensure smooth demolding, minimize flash and surface defects on transparent components, while facilitating easier mold maintenance and cleaning.

● High-Efficiency Cooling System: Featuring multi-channel precision cooling circuits, our molds accelerate plastic solidification, significantly reducing cycle times while improving production efficiency and lowering energy consumption.

● Surface Treatment Technology: The mold cavity undergoes precision polishing to deliver flawlessly smooth surfaces of chairs, effectively eliminating secondary finishing processes.

(2)Product application

● Furniture Brand Collaboration: Kaihua's transparent injection chair molds create exclusive products for globally renowned furniture brands, meeting their stringent requirements for design aesthetics and premium quality.

● Home Retail Supply: The finished products from our clear chair injection molds are ideally suited for home furnishing retailers to build cost-effective product lines, ensuring market-leading standards in both functionality and visual appeal to drive end-consumer sales.

● International Home Furnishings Trade: Leveraging Kaihua's flexible and high-performance mold technology, we serve global home furnishing markets by ensuring products meet regional quality, safety and environmental standards, delivering consistently reliable quality in cross-border trade.

5.Product qualification

(1)Production Process of Clear Chair Injection Mold

● Mold Clamping: The mold halves are securely closed and locked in position to ensure proper alignment and complete sealing.

● Material Loading: Pre-dried plastic pellets are loaded into the injection molding machine's hopper.

● Melting Phase: The injection molding machine heats the plastic pellets until completely molten.

● Injection Phase: The molten plastic is forced into the mold cavity under high pressure through the injection unit..

● Pressure Maintenance: Maintaining appropriate pressure within the mold ensures complete plastic filling of the cavity.

● Cooling Phase: Allow the injected plastic to cool and solidify within the mold, taking on the desired shape.

● Ejection: Carefully open the mold and eject the finished plastic product.

(2)Product shipment and packaging photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here

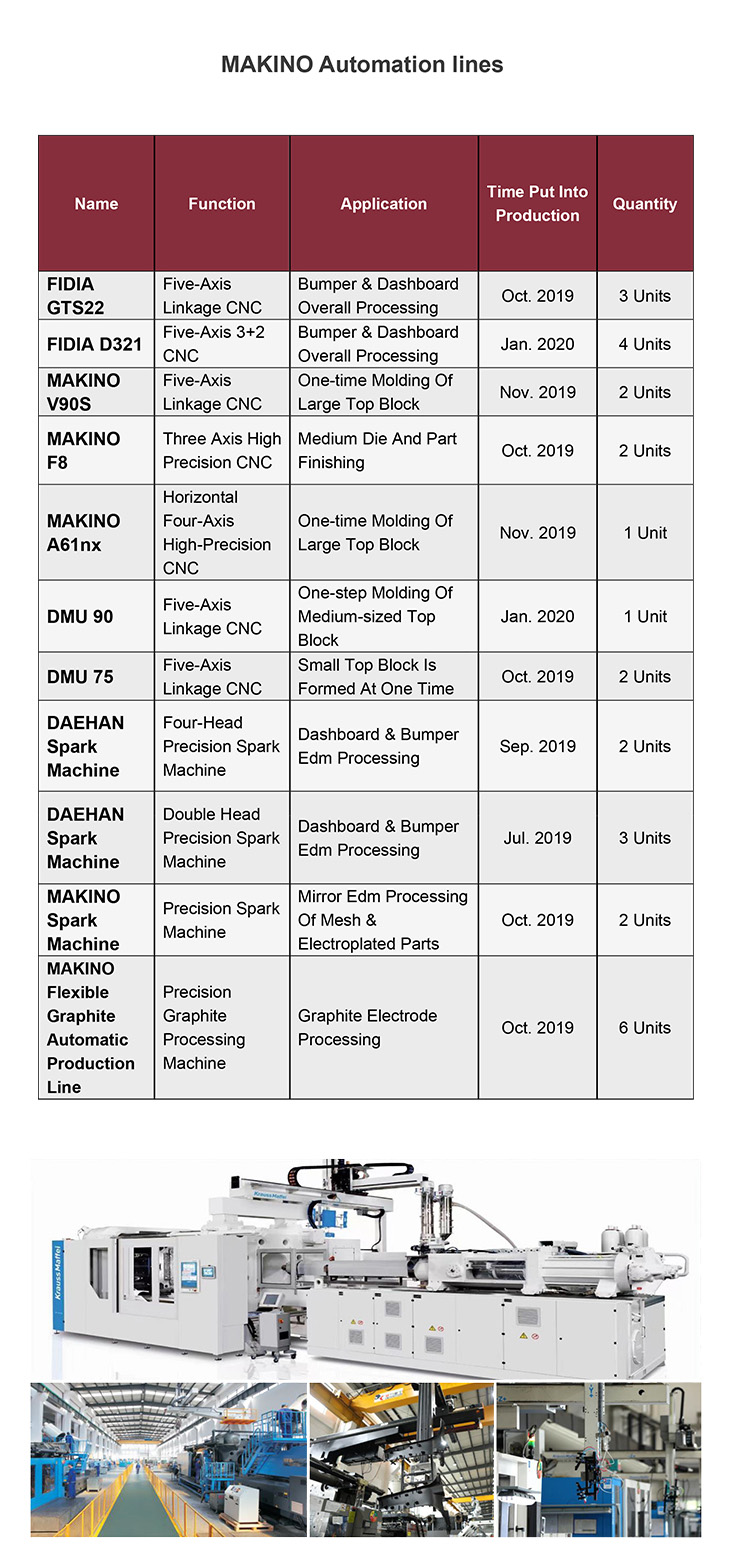

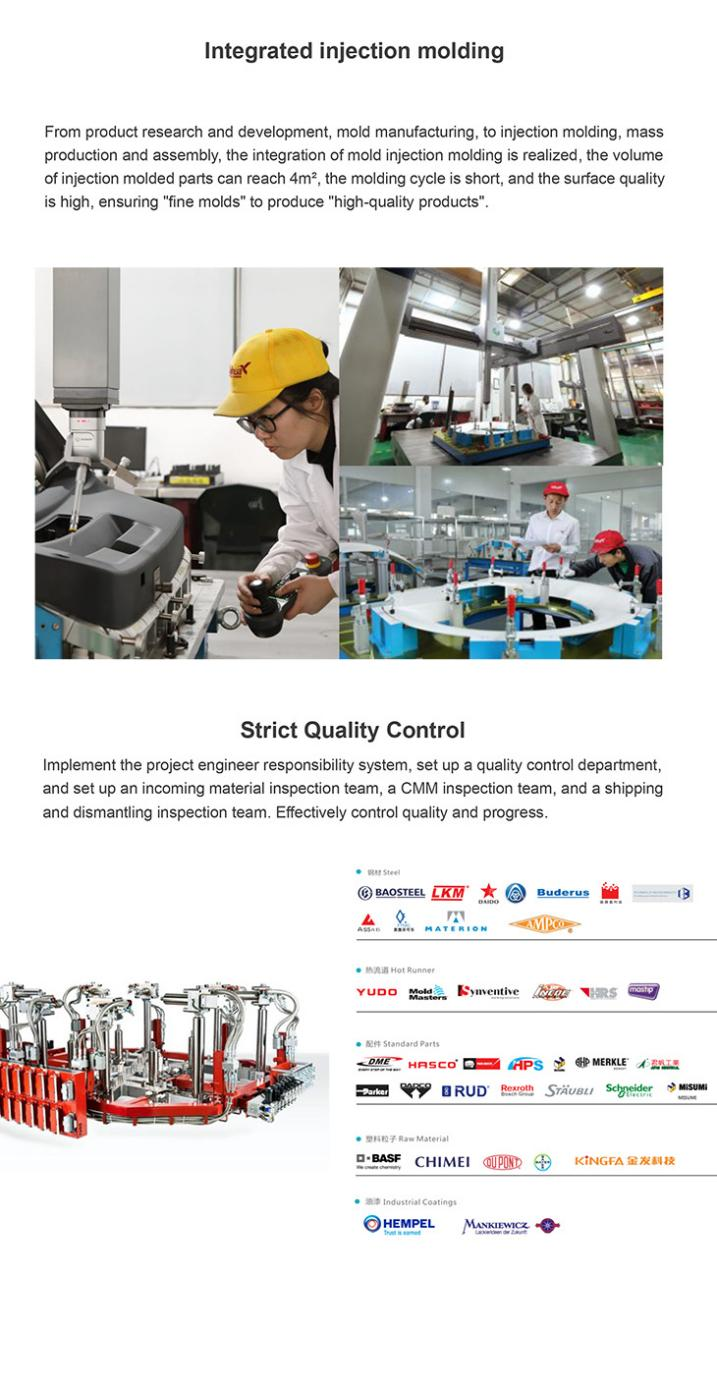

7.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua's advantages,experience our professional strength and quality assurance!

8.FAQ