Door Panel Injection Mold

1. Product Introduction

At KaiHua Mould, we take pride in creating top-quality Door Panel Injection Molds that meet the industry's top standards. KaiHua wide selection includes molds for different door parts like the Left Rear Door Lower Body, Right Front Door Scuff Plate Lower Body, Left/Right Front Door Center Trim Panels, as well as Inner Release Handle Covers, Armrests, Switch Panels, and Trim Panel Frames for both left and right front doors. Each part is carefully designed and built with advanced technology to ensure excellent performance and durability.

At KaiHua, we make molds with precision to fit the exact needs of automotive makers. Whether you're looking for a single mold or a full set for your car door panels, KaiHua factory can provide you with superior products that not only work well but also look great.

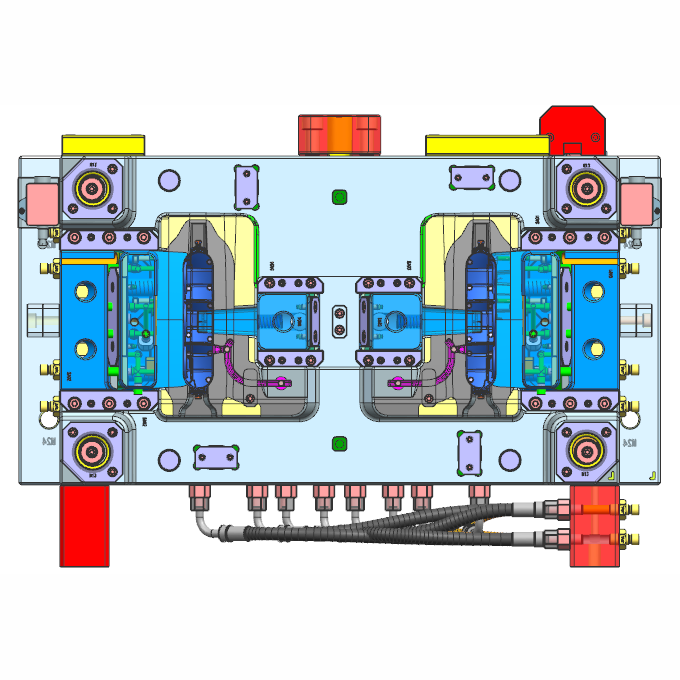

2. Case Product Parameters

|

Part Name |

left rear door inner panel |

|

Mold size |

1450X1300X1130 |

|

Mold weight(t) |

1.18 |

|

Product size(mm) |

783X631X140 |

|

grain or electroplate |

Grain |

|

Demolding requirement |

Gripper |

|

Product materials |

PP+EPDM-T20 |

|

Injection Machine(t) |

1600 |

|

cavity number |

1+1 |

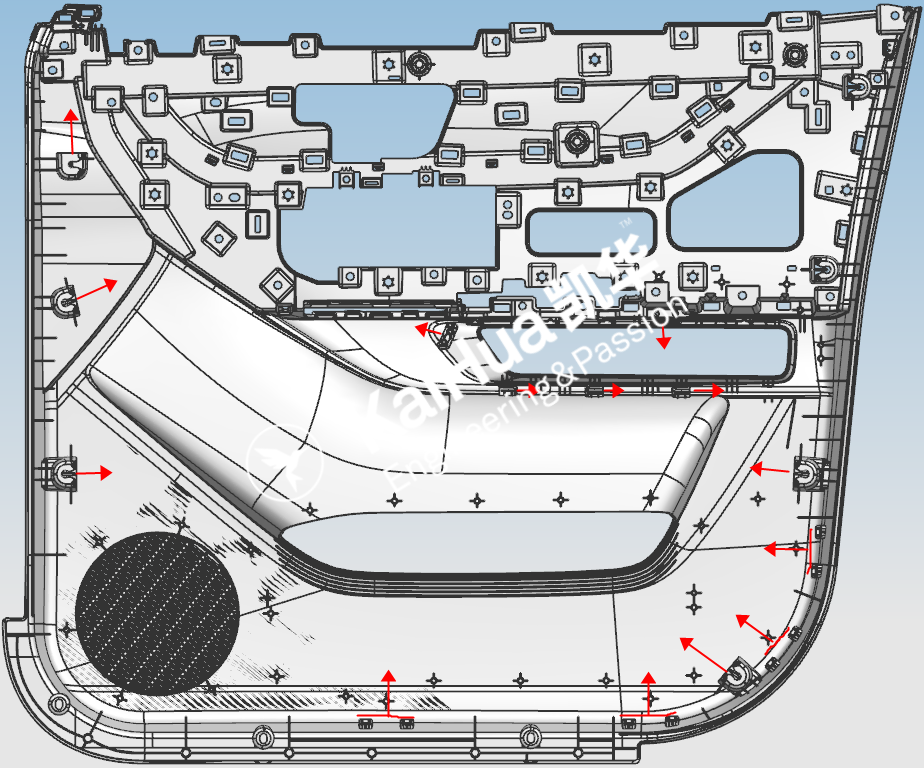

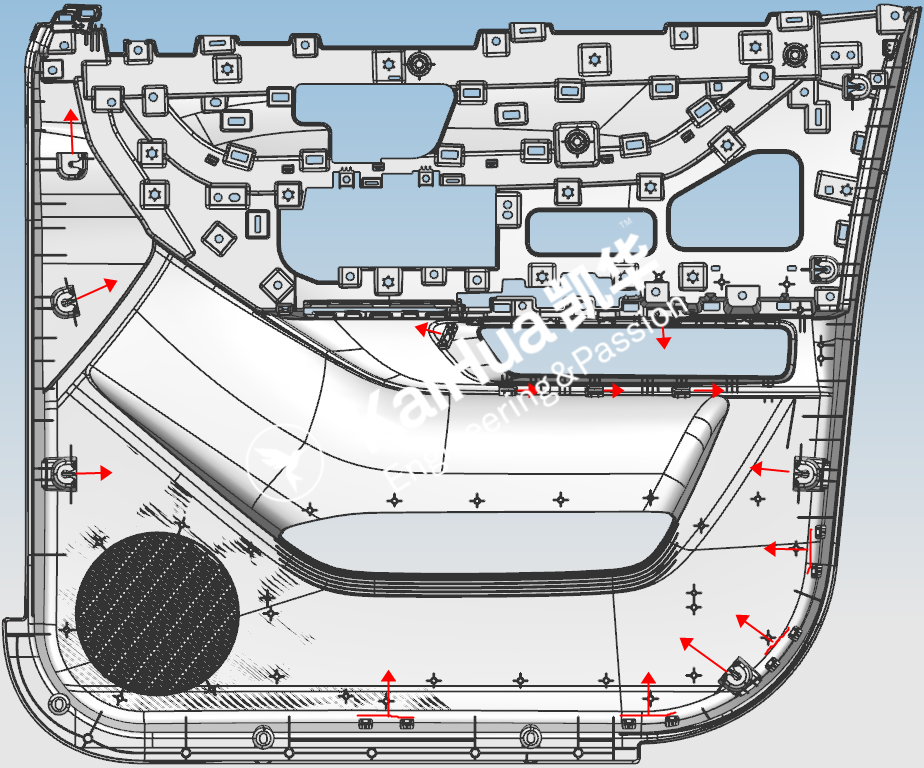

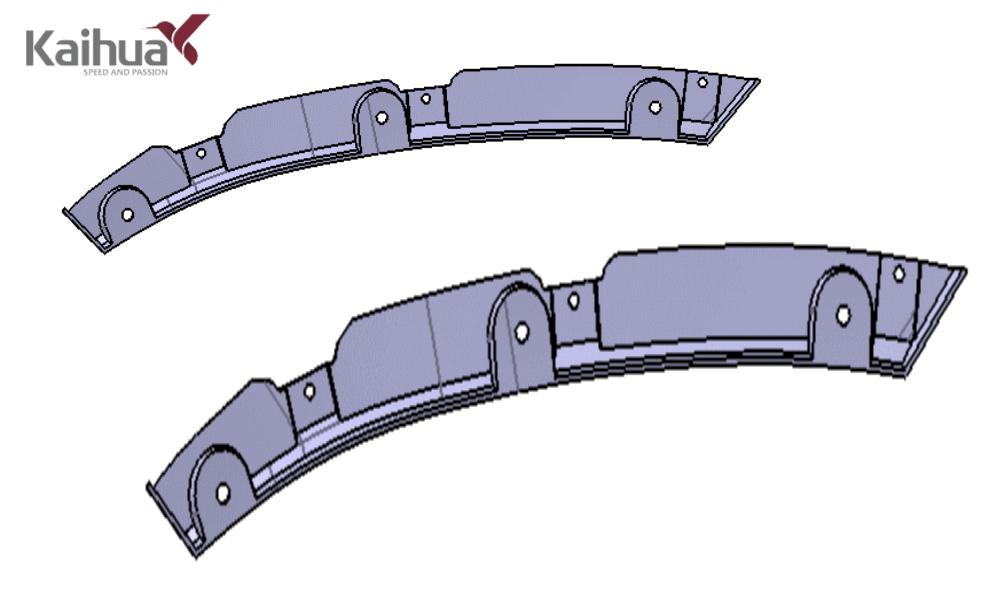

3. Product Display

|

Left front door inner panel |

Right front door inner panel |

Front door scuff plate inner panel |

Rear door scuff plate inner panel |

Right rear door inner panel |

Left and right front door scuff plates |

|

Left/Right door map pocket |

Left/Right front door inner release handle cover |

Left/Right front door armrest |

Left/Right front door switch panel |

Left and right front door armrest frame |

Left and right front door tweeter bracket |

4.Production details

5.Product feature and application

Kaihua Mold demonstrates exceptional expertise in refrigerator door liner mold manufacturing by seamlessly integrating research, design and development to achieve perfect harmony between functionality and aesthetics. From initial market research to structural optimization, our engineering team applies lightweight concepts and ergonomic design principles to maximize space utilization while ensuring user-friendly operation.

During production, Kaihua employs innovative thin wall injection molding and gas-assisted injection molding technologies to reduce weight while maintaining structural integrity, effectively lowering material costs. Our proprietary in-mold degassing technology eliminates air bubbles during forming, guaranteeing flawlessly smooth surfaces and premium product quality. The application of laminated molding techniques enhances the liner's wear resistance and impact strength.

Through low-pressure injection molding and free-spray coating technologies, we achieve precise dimensional accuracy while offering diverse aesthetic finishes. These advanced manufacturing processes and technical innovations enable Kaihua to deliver highly efficient, superior quality and market-competitive refrigerator door liner mold solutions for our global clients.

6.Prodect qualification

(1)Product shipment and packaging photos

(2)Design review photos

(3)Photos of the Technical Department Meeting

(4)Certificate

8.FAQ