Kaihua Mold: Plastic Chair Mold with Gas Assistant Technology – Premium Solutions for Comfort & Durability

Kaihua Mold: Plastic Chair Mold with Gas Assistant Technology – Premium Solutions for Comfort & Durability,

,

1.Product Introduction

he Kaihua gas assistance injection mold of chair adopt an intelligent production line to innovate the traditional manufacturing process. Workers only need to complete the clamping of iron materials and feeding of materials, while the rest of the processes such as feeding, processing, and unloading are all automatically completed by high-precision robots.

In addition, the interchangeable design of the molds is a major highlight. Through a modular structure, the production switch of chairs in different styles and sizes can be easily achieved to meet diverse market demands. With the advantages of lightweight, high efficiency, and high flexibility, the molds adopt the advanced gas-assisted injection molding technology. The created hollow chair frame has the dual advantages of being lightweight and high-strength. The modular design supports quick mold changing to meet diversified needs.

With the perfect combination of intelligent manufacturing and innovative craftsmanship, Kaihua provides customers with high-cost-effective and fast-delivery high-quality product solutions, helping customers gain a competitive edge in the market.

2.Case Product Parameters

|

Product Name |

Gas assistance chair |

|

Plastic material |

PP+30% Fiberglass |

|

Product weight (g) |

3800 |

|

Product size |

667X566X396 |

|

Product wall thickness(mm) |

/ |

|

Mold weight(t) |

6.168 |

|

Mold size |

1250*850*870 |

|

Injection molding machine tonnage |

1200 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

grain+polishing |

|

Automatic demolding requirements |

robot |

|

Product Name |

Seat pan |

|

Plastic material |

PP+30% Fiberglass |

|

Product weight (g) |

2700 |

|

Product size |

446X64X420 |

|

Product wall thickness(mm) |

8 |

|

Mold weight(t) |

1.685 |

|

Mold size |

700*650*555 |

|

Injection molding machine tonnage |

480 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

grain+polishing |

|

Automatic demolding requirements |

robot |

3.Product details

4.Product feature and application

(1)Product Feature:

Kaihua’s gas assistance injection mold of chairs deliver exceptional advantages: effectively reducing product residual stress and warpage while eliminating surface sink marks; significantly lowering required clamping force by 40%-60% to extend equipment lifespan; saving 20%-40% material usage without dimensional changes while shortening cycle time by 30%; additionally reducing mold pressure, minimizing tool wear, and simplifying product design, achieving optimal quality with cost efficiency.

(2)Product Application:

Kaihua’s gas assistance injection mold of chairs offer versatile applications across multiple settings. In residential environments, they serve as premium daily seating solutions, delivering exceptional comfort for living room relaxation and dining room use through their advanced ergonomic design. For office applications, these molds effectively enhance workplace comfort, reducing physical fatigue while boosting productivity. In public spaces such as waiting areas and conference rooms, their proven durability and stability reliably accommodate high-traffic usage, making them an ideal combination of functional performance and quality craftsmanship.

5.Product qualification

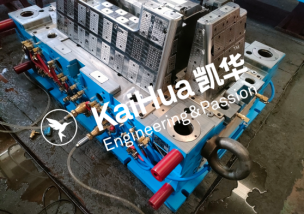

(1)Mold water test photos

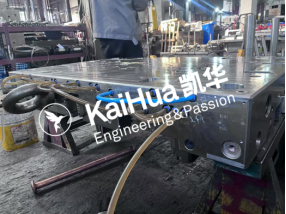

(2)Mold shipment photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua’s certificates, please click here

7.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua’s advantages,experience our professional strength and quality assurance!

8.FAQ

Kaihua’s plastic chair mold with gas assistant technology redefines chair manufacturing by addressing core pain points of traditional molds. Tailored for PP, ABS, and HIPS materials commonly used in plastic chairs, this mold integrates advanced gas-assisted injection technology to eliminate sink marks, shrinkage, and internal stress—common flaws in thick-walled areas like chair backs, armrests, and leg connections. The optimized gas channel design ensures uniform melt filling, creating chairs with smooth, blemish-free surfaces that meet high aesthetic standards, while the hollowed internal structure (enabled by gas assistance) reduces material usage without compromising load-bearing capacity or structural stability.

Backed by Kaihua’s precision engineering, the mold features CNC-machined cavities with wear-resistant mold steel, ensuring long service life for mass production. It supports customization for diverse chair types—from office chairs and dining chairs to outdoor leisure chairs—adapting gas injection parameters and mold structures to match specific design requirements (e.g., curved armrests, ergonomic backrests). With intelligent process monitoring and standardized components, the mold streamlines production, reduces scrap rates, and shortens lead times, making it an ideal choice for home furniture and commercial seating brands. Plus, the eco-friendly design aligns with green manufacturing trends, minimizing material waste while delivering high-performance plastic chairs.