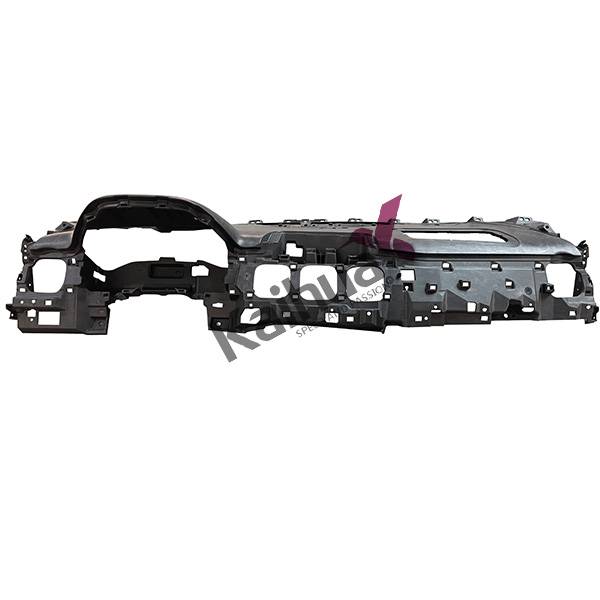

Kaihua Mucell Dashboard Tooling Automotive Mold Maker

1.Product Introduction

Kaihua's Mucell dashboard injection molds set industry standards for automotive interior manufacturing, merging cutting-edge Mucell technology with precision engineering. As pioneers in Mucell mold development—with 38 successful projects and 20+ years of expertise—we’ve refined these tools to meet global automakers’ stringent demands, as demonstrated by our solution for the FORD CD391 Mondeo (Left-Hand Drive) and beyond.

At their core, these molds leverage Mucell technology: supercritical fluid (CO₂ or N₂) injected into molten plastic creates 5-50μm microcells, slashing weight by 15-20% without sacrificing strength. This delivers panels with superior dimensional stability and surface quality, aligning with the industry’s focus on fuel efficiency and performance.

Complemented by physical foaming and injection compression processes, the molds eliminate defects like sink marks and weld lines. Enhanced by Kaihua’s B-side structural design expertise, they optimize durability and assembly compatibility, ensuring seamless integration with diverse production lines while supporting high-volume manufacturing with consistent quality.

In addition, two of Kaihua's prominent Automobile Plastic Injection Molds—the Car Door Panel Injection Mold with Stack Mould Technology and the Car Door Panel Injection Mould with Gas Assistance Technology—have received wide praise in the industry.

2.Case Product Parameters

|

Product Name |

FORD CD391 Mondeo |

|

Plastic Material |

PP, ABS, and other automotive-grade plastics (optimized for Mucell) |

|

Injection Molding Machine Tonnage |

1600-2000T |

|

Number of Mold Cavities |

1 |

|

Mold Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Mold Size |

2300*1800*1500mm |

|

Mold Weight |

27.2Ton |

|

Grain or Electroplate |

Polished |

|

Automatic Demolding Requirements |

Robot |

|

Hot Runner |

16-point sequential valve (Synventive) |

|

Molding Cycle |

63s |

3.Product Display

| • FORD V362 IP body skeleton | • FORD BX726 IP LOWER LHD |

| • FORD BX726 DEFROST PNL LHD | • FORD B515IP LOWER BOD |

| • FORD BX726 IP WING PNL SUBSTRATE LHD | • FORD BX726 IP LOWER LHD |

| • FORD BX726 IP WING PNL SUBSTRATE RHD | • FORD BX726 IP LOWER LHD |

| • FORD BX726 IP LOWER RHD | • FORD U625 Instrument Panel Body |

| • FORD B515 Instrument Panel Body | • FORD CD 539 Instrument Panel Body |

4.Production details

(1)Wrap the waterway with adhesive tape according to customer requirements

(2)Spray paint according to customer requirements

5.Product feature and application

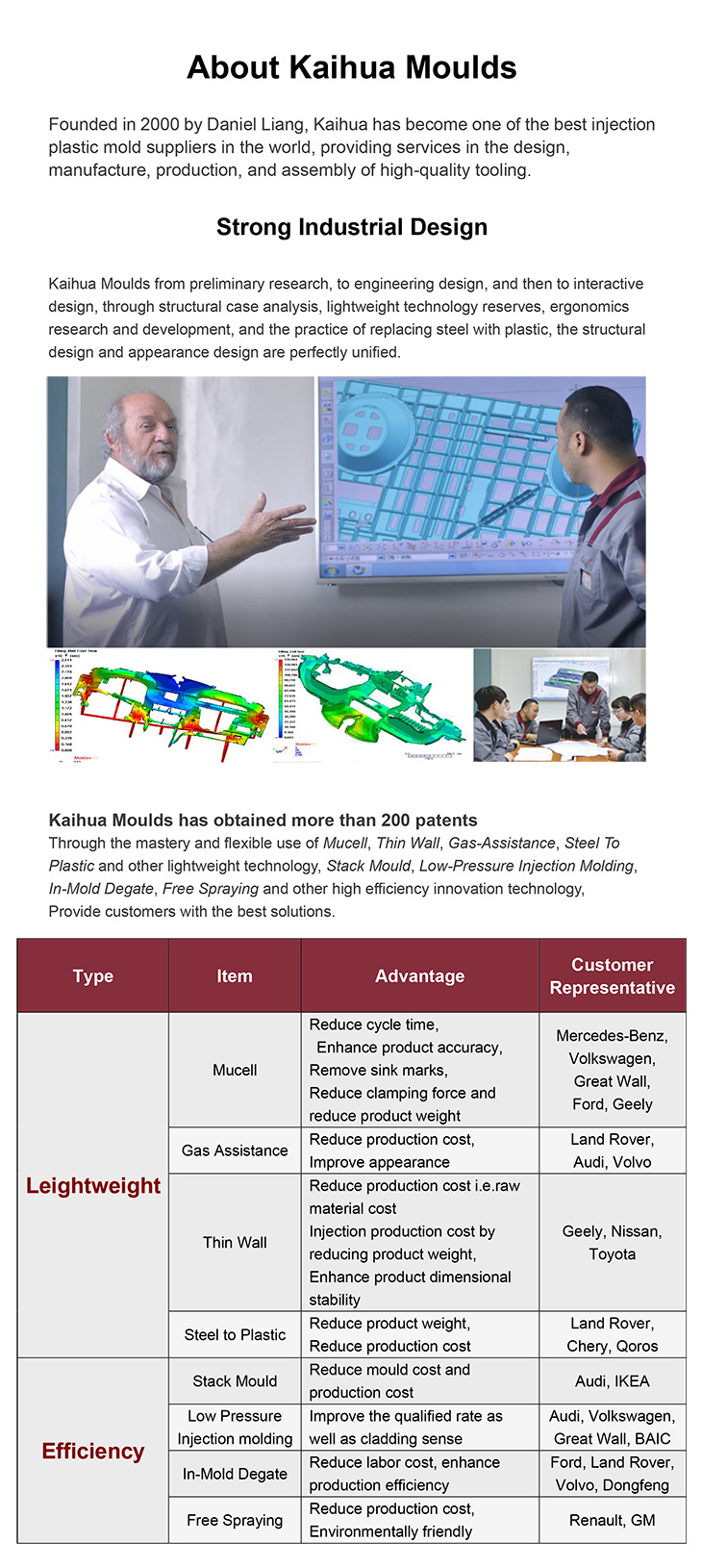

Kaihua’s Automotive Instrument Panel Injection Molds (IP Molds) cover the full lifecycle—from preliminary research and engineering design to interactive design. By integrating structural case analysis, lightweight tech reserves, ergonomic R&D, and steel-to-plastic replacement practices, we perfectly unify structural and aesthetic design.

Mastering and flexibly applying key technologies—including Mucell, Thin Wall, Gas-Assistance, and Steel To Plastic for lightweighting, plus Stack Mould, Low-Pressure Injection Molding, In-Mold Degate, and Free Spraying for high efficiency—we deliver optimal solutions to every customer.

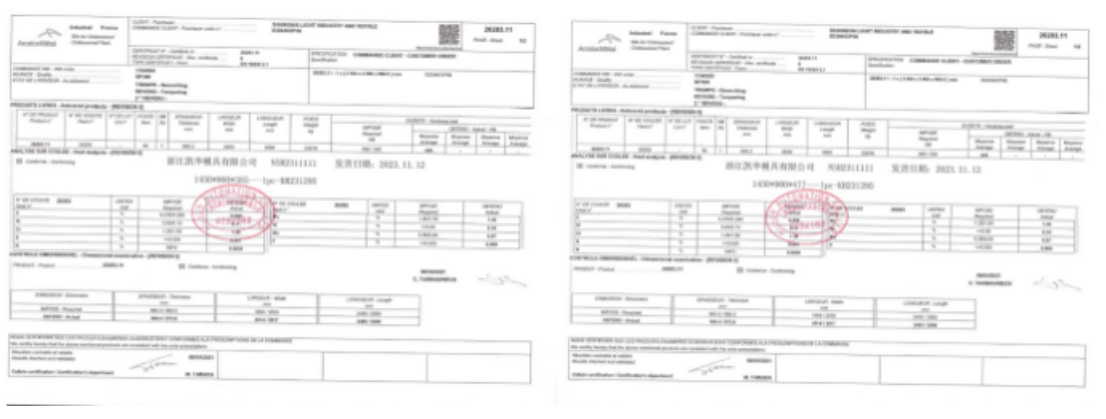

6.Prodect qualification

(1)Production process

· Closing the mold: Close the mold to ensure it is in place.

· Feeding: Add the dried plastic pellets into the hopper of the injection molding machine.

· Melting: Heating the injection molding machine to melt the plastic particles.

· Injection: Molten plastic is injected into a mold through an injection device.

· Pressure holding: Maintain a certain pressure in the mold to fully fill the mold with plastic.

· Cooling: Cooling and solidifying in the mold to shape the plastic.

· Demoulding: Open the mold and remove the plastic product.

(2)Car Dashboard of Plastic Injection Mold Trial Video

(3)Product shipment and packaging photos

(4)Technical team

| Responsibilities of project members | Main responsibilities |

| project manager | Supervise the entire project planning and control the quality, time, and cost of the project |

| Quality Manager | Responsible for project quality matters |

| salesman | Responsible for project business and logistics work |

| Design team leader | Responsible for reviewing and guiding product analysis and design, as well as mold structure design |

| Process Supervisor | Responsible for the development of mold production processes and production management |

| Mold Supervisor | Responsible for the research and assembly of molds, as well as guidance on mold technology |

(5)Design review photos

(6)Photos of the Technical Department Meeting

(7)Design review photos

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

8.FAQ