Kaihua Refrigerator Drawer Injection Mould: The Ultimate Solution for Premium Drawer Production

To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Kaihua Refrigerator Drawer Injection Mould: The Ultimate Solution for Premium Drawer Production, In order to expand our international market, we mainly supply our oversea customers Top quality performance products and service.

To constantly improve the management system by virtue of the rule of “sincerely, good faith and quality are the base of enterprise development”, we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for , We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there’s any opportunity, welcome to visit our factory!!!

1.Product Introduction

he Kaihua gas assistance injection mold of chair adopt an intelligent production line to innovate the traditional manufacturing process. Workers only need to complete the clamping of iron materials and feeding of materials, while the rest of the processes such as feeding, processing, and unloading are all automatically completed by high-precision robots.

In addition, the interchangeable design of the molds is a major highlight. Through a modular structure, the production switch of chairs in different styles and sizes can be easily achieved to meet diverse market demands. With the advantages of lightweight, high efficiency, and high flexibility, the molds adopt the advanced gas-assisted injection molding technology. The created hollow chair frame has the dual advantages of being lightweight and high-strength. The modular design supports quick mold changing to meet diversified needs.

With the perfect combination of intelligent manufacturing and innovative craftsmanship, Kaihua provides customers with high-cost-effective and fast-delivery high-quality product solutions, helping customers gain a competitive edge in the market.

2.Case Product Parameters

|

Product Name |

Gas assistance chair |

|

Plastic material |

PP+30% Fiberglass |

|

Product weight (g) |

3800 |

|

Product size |

667X566X396 |

|

Product wall thickness(mm) |

/ |

|

Mold weight(t) |

6.168 |

|

Mold size |

1250*850*870 |

|

Injection molding machine tonnage |

1200 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

grain+polishing |

|

Automatic demolding requirements |

robot |

|

Product Name |

Seat pan |

|

Plastic material |

PP+30% Fiberglass |

|

Product weight (g) |

2700 |

|

Product size |

446X64X420 |

|

Product wall thickness(mm) |

8 |

|

Mold weight(t) |

1.685 |

|

Mold size |

700*650*555 |

|

Injection molding machine tonnage |

480 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

grain+polishing |

|

Automatic demolding requirements |

robot |

3.Product details

4.Product feature and application

(1)Product Feature:

Kaihua’s gas assistance injection mold of chairs deliver exceptional advantages: effectively reducing product residual stress and warpage while eliminating surface sink marks; significantly lowering required clamping force by 40%-60% to extend equipment lifespan; saving 20%-40% material usage without dimensional changes while shortening cycle time by 30%; additionally reducing mold pressure, minimizing tool wear, and simplifying product design, achieving optimal quality with cost efficiency.

(2)Product Application:

Kaihua’s gas assistance injection mold of chairs offer versatile applications across multiple settings. In residential environments, they serve as premium daily seating solutions, delivering exceptional comfort for living room relaxation and dining room use through their advanced ergonomic design. For office applications, these molds effectively enhance workplace comfort, reducing physical fatigue while boosting productivity. In public spaces such as waiting areas and conference rooms, their proven durability and stability reliably accommodate high-traffic usage, making them an ideal combination of functional performance and quality craftsmanship.

5.Product qualification

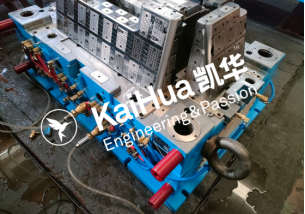

(1)Mold water test photos

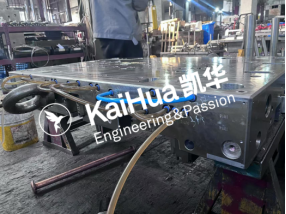

(2)Mold shipment photos

(3)Design review photos

To learn more about Kaihua’s certificates, please click here

(4)Photos of the Technical Department Meeting

(5)Certificate

7.Kaihua Mould Advantage

Click here,gain a deeper understanding of Kaihua’s advantages,experience our professional strength and quality assurance!

8.FAQ

Kaihua’s refrigerator drawer injection moulds are engineered to excel in every critical aspect of drawer manufacturing, starting with adaptive designs that tackle diverse use cases—for freezer drawers, reinforced cavity walls and anti-condensation inserts ensure resistance to low-temperature brittleness and stable load-bearing, while multi-compartment drawers benefit from precision interlocking cores that guarantee perfect divider alignment. We’ve optimized for material versatility too, adjusting flow channels and gates to suit HIPS, PP, ABS, PET, and PC, ensuring smooth filling and structural integrity no matter the material, and targeted reinforcement ribs at stress points (like edges and handles) prevent warping or cracking during use. For transparent drawers, 8-level mirror polishing and advanced hot runners deliver exceptional light transmittance and zero weld lines, while segmented cooling circuits balance temperature across uneven thicknesses, eliminating sink marks and internal stress.

Kaihua’s refrigerator drawer injection moulds are engineered to excel in every critical aspect of drawer manufacturing, starting with adaptive designs that tackle diverse use cases—for freezer drawers, reinforced cavity walls and anti-condensation inserts ensure resistance to low-temperature brittleness and stable load-bearing, while multi-compartment drawers benefit from precision interlocking cores that guarantee perfect divider alignment. We’ve optimized for material versatility too, adjusting flow channels and gates to suit HIPS, PP, ABS, PET, and PC, ensuring smooth filling and structural integrity no matter the material, and targeted reinforcement ribs at stress points (like edges and handles) prevent warping or cracking during use. For transparent drawers, 8-level mirror polishing and advanced hot runners deliver exceptional light transmittance and zero weld lines, while segmented cooling circuits balance temperature across uneven thicknesses, eliminating sink marks and internal stress.

Beyond performance, we prioritize practicality: assembly-precise positioning grooves let formed drawers align seamlessly with rails and gaskets, reducing manual adjustments; specialized texture processing and wear-resistant cores maintain anti-slip performance and durability; and easy-maintenance structures simplify component disassembly for cleaning or replacement. Intelligent monitoring ports track production in real time to cut scrap rates, while standardized quick-change interfaces boost agility for multi-model runs. We also support customization—integrating hidden handles, drainage holes, or label positions directly into the mould to skip secondary processing—and align with green production via waste-reducing runners and eco-friendly materials. From standard to transparent drawers, Kaihua’s moulds don’t just meet expectations—they elevate drawer quality, streamline production, and adapt to every client’s unique needs, making them the trusted choice for home appliance brands aiming for excellence.