Mold

-

Door Panel Injection Mold

KaiHua Company focuses on designing and building top-notch injection molds for door panels. Kaihua molds, such as the Left Rear Door Lower Body, Right Front Door Scuff Plate Lower Body, and Left/Right Front Door Center Trim Panels, among others, are made with attention to detail, strength, and effectiveness. With more than 20 years in the business, KaiHua Factory is a reliable source for all your door panel injection mold requirements. -

Foldable Crate Mold

Discover the Foldable Crate Mold by KaiHua mould, the ultimate tool for enhancing logistics efficiency. Specifically crafted for a wide range of industries, from mechanics to electronics, KaiHua mold allows for the production of Foldable crates that boast impressive qualities. These crates are corrosion-resistant, oil-stain proof, non-toxic, and odorless, with exceptional sealability and moisture resistance. By choosing KaiHua mold, you can optimize your storage and transportation needs effortlessly. -

Refrigerator Door Liner Mold of Home Appliance

Kaihua Mold, a leader in the mold manufacturing industry, has established outstanding expertise in the home appliance mold sector. Its Injection mold of refrigerator drawer, Injection mold of AC Components, Plastic Cover for Electric Cooker, Plastic Cover for Television, Plastic Cover for Air Conditioner and Plastic Cover for Air Purifier are widely recognized by clients for their superior quality. Since its founding in 2000, Kaihua has dedicated over two decades to injection mold development, accumulating profound experience and driving continuous innovation in specialized home appliance mold solutions.

From project initiation, Kaihua’s professional team collaborates closely with clients to deliver customized solutions tailored to specific requirements. During the design phase, the company integrates cutting-edge concepts and advanced technologies to ensure product functionality, aesthetics, and manufacturing efficiency. In production, Kaihua leverages state-of-the-art equipment, combined with its KMS (Key Management System) for lean manufacturing and KMVE (Kaihua Mold Value Engineering) system, to maintain stringent quality control. Innovations in cooling system design accelerate liner cooling and solidification, shortening production cycles, while optimized trimming technology ensures precise cuts and smooth edges, reducing the need for additional polishing. Every stage—from raw material procurement to production workflows and final inspection—undergoes meticulous monitoring.

With exceptional quality and efficient service, Kaihua Mold has become a trusted partner for refrigerator door liner molds, helping clients gain a competitive edge in the market. -

Rattan Chair Mold of Outdoor Furniture

Kaihua's innovative rattan chair molds masterfully replicate natural rattan's authentic texture and elegant curves through precision CNC engraving and multi-layer etching technology. The result is synthetic wicker with remarkably lifelike woven patterns that surpass natural rattan in durability - eliminating common issues like fraying and deformation. Specifically engineered for outdoor use, these advanced molds enhance material flow and structural stability to produce weather-resistant chairs that withstand extreme conditions. The finished products maintain perfect shape without cracking or sagging, even under prolonged sun exposure and high humidity. This breakthrough technology delivers the classic rattan aesthetic with unmatched resilience for modern outdoor living.

Kaihua's molds boost production efficiency while supporting sustainability, featuring compatibility with recycled composites and bio-based resins. The innovative design enables single-step molding of complex curves, minimizing post-processing. Integrated precision cooling and modular construction accelerate cycle times while ensuring consistent quality in mass production. These technologically advanced molds deliver artisanal aesthetics with industrial-strength durability, setting new benchmarks for outdoor furniture that perfectly balances form and function.

Kaihua has also earned strong market recognition for its premium Chair Injection Mold with Gas-Assisted Technology and clear chair molds, which have gained widespread acclaim from both new and established clients.

-

Injection mold of refrigerator drawer

Kaihua mold specializes in the production of high quality injection mold of refrigerator drawer, offering a comprehensive range of products including Refrigerator crisper drawer for fruit and vegetable preservation, freezer sliding track drawers, and multi-functional layered storage containers. Our core strengths lie in MuCell, exceptional durability, and customizable design solutions. With years of experience serving globally renowned home appliance brands, we provide end-to-end solutions from mold development to mass production optimization, ensuring efficient delivery and consistent quality standards. Kaihua mold specializes in manufacturing high quality home appliances, including injection mold of AC Components, Plastic Cover of Air purifier, Electric Cooker and Television. Kaihua factory is your trusted partner for all home appliance injection mold requirements. -

Chair injection mold with gas-assisted technology

Kaihua's Gas assistance chair molds integrate precision mold technology with practical design, achieving breakthroughs in furniture manufacturing. These advanced molds utilize gas assistance technology to precisely control gas injection molding, creating hollow structures during molding. This process significantly reduces product weight while dramatically improving material efficiency.

Gas-assisted injection molding technology offers significant advantages in mold production, not only reducing production costs but also decreasing product weight while shortening cycle time and improving appearance. The process begins with a short shot of molten plastic filling 60-95% of the mold cavity. High-pressure nitrogen gas is then injected to push the melt to completely fill the cavity while creating hollow sections. During the gas holding phase, continuous pressure ensures smooth surface finish and compensates for shrinkage. After cooling, the gas is vented and the part is ejected. This method is widely used to produce chair components like armrests and backrests, achieving lightweight designs without compromising structural integrity while significantly boosting production efficiency and cost-effectiveness.

Additionally, Kaihua mold possesses extensive expertise in manufacturing Outdoor leisure plastic chairs and Kid plastic chair, consistently delivering safe, durable, and internationally certified seating solutions to global clients. Choose Kaihua for guaranteed quality. -

Injection Mold Of AC Components

Kaihua’s injection mold of AC components exemplify our relentless pursuit of perfection in HVAC manufacturing. Renowned for precision engineering and superior craftsmanship, these Air Conditioning injection mold components incorporate cutting-edge technologies and premium materials to ensure durability and reliable protection for HVAC internal structures. With a robust design, Kaihua’s plastic mold of Air Conditioning Components units deliver exceptional cost-performance and extended service life, offering businesses a solid return on investment (ROI). Engineered for easy installation and seamless integration, they complement various Injection mold of Air Conditioning Components, enhancing both aesthetic appeal and operational efficiency. Whether meeting basic functional requirements or addressing complex high-end HVAC designs, Kaihua’s AC Injection mold components adhere to stringent industry standards. Committed to consistent reliability and peak performance, we guarantee top-tier quality that aligns with global HVAC specifications. With decades of specialization in appliance mold manufacturing, Kaihua has established unmatched expertise across the industry. Choose Kaihua for comprehensive technical support and innovative mold solutions. Partner with us to establish long-term collaboration built on trust, expertise, and mutually beneficial growth in the HVAC components industry. -

Car Glove Box Plastic Injection Mold

Experience precision engineering with the Car Glove Box Plastic Injection Mold from KaiHua Mould. Specially designed for automotive interiors, KaiHua mold guarantees high-quality, durable Car Glove Box components. Trust KaiHua for seamless production and customization options tailored to your needs. -

Double-deck Plastic Pallet Mould of Injection Mold

Kaihua Mold is a professional molding company specializing in Double-deck Plastic Pallet Moulds. Kaihua has 25 years of experience in this industry and is committed to producing high-quality molds. Kaihua Double-deck Plastic Pallet Mould are made of high-quality materials, which are efficient and cost-effective, with excellent durability, ensuring a long service life. The design of Double-deck Plastic Pallet Mould has been optimized for easy handling and transportation, making them an ideal choice for industrial and commercial applications. Whether you need pallets for basic storage or more complex logistics operations, Double-deck Plastic Pallet can provide the reliability and performance your business needs. -

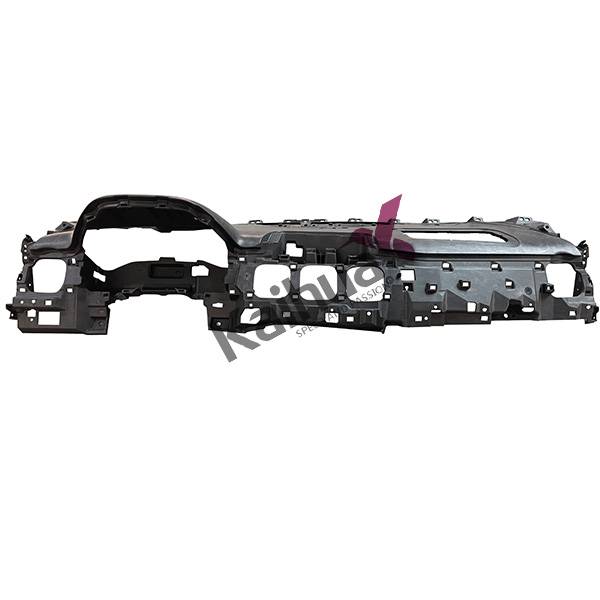

Car Dashboard Mould of Plastic Injection Mold

Kaihua Mold is a professional Car Dashboard Mould manufacturers and all-round solution provider. Kaihua automobile Instrument Panel Injection Molds ( IP Mold ) are of the highest quality and are designed to meet the specific needs of automotive manufacturers. Kaihua team of experts works closely with clients to ensure that their needs are fully met, and Kaihua are committed to providing the best possible service to customers. Kaihua specialize in injection moulding automotive mold and are one of the leading providers in China. Trust Kaihua Mold to provide you with the best quality products and services for all your automobile instrument panel injection molds ( IP Mold ) needs. -

Kids Toddler Climber with Slide for Indoor& Outdoor Injection Mold

Kahua Moulds: Your Solution to Kids Toddler Climber with Slide for Indoor& Outdoor Injection Mold Injection Molds

Are you in need of a reliable injection mold supplier for your Kids Toddler Climber products? Look no further than Kahua Moulds!

We specialize in providing both the outer shells and internal parts for Kids Toddler Climbers. Our injection molds are made with high-quality materials and undergo rigorous testing to ensure optimal performance and longevity.

Our team of experienced professionals is committed to providing exceptional customer service, timely delivery, and competitive pricing. We understand the importance of quality products and strive to exceed our customer's expectations.

At Kahua Moulds, we offer a wide range of injection molds, including those for Kids Toddler Climbers. Whether you need a new mold or a replacement, we have the solution for you.

Contact us today to learn more about our Kids Toddler Climber injection molds and other services! -

Automobile instrument panel mould

Kaihua Moulds is a professional mould maker and all-round solution provider for Automobile Instrument Panel Mould ( IP Mold ). Our Automobile Instrument Panel Injection Molds ( IP Mold ) are of the highest quality and are designed to meet the specific needs of automotive manufacturers. Our team of experts works closely with clients to ensure that their needs are fully met, and we are committed to providing the best possible service to our customers. We specialize in Injection Moulding and Automotive Mold and are one of the leading providers in China. Trust Kaihua Moulds to provide you with the best quality products and services for all your Automobile Instrument Panel Injection Molds ( IP Mold ) needs.