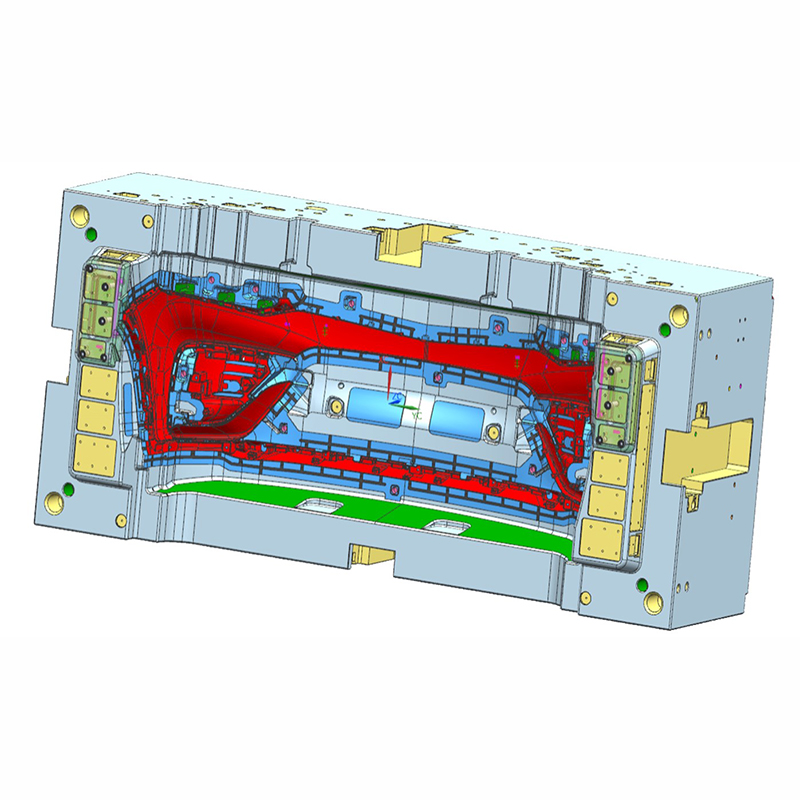

Mud Flap of Plastic Injection Mold

1.Product Introduction

Kaihua delivers high-performance Mud Flap Injection Mold solutions designed to meet the demanding requirements of automotive manufacturing. Each Car Mud Flap Mold and Truck Mud Flap Mold is produced with precision engineering to ensure durability, accuracy, and stable performance in high-volume production.

Built with advanced tooling materials such as 718H and NAK80 steel, our molds guarantee long service life, excellent wear resistance, and the surface quality needed for exterior components. Combined with technologies like precision CNC machining, gas-assisted molding, and MuCell micro-foaming, every Mudguard Injection Mold achieves superior dimensional accuracy and smooth finishes.

Whether for Custom Mud Flap Mold, Splash Guard Injection Mold, or OEM automotive projects, Kaihua ensures short lead times, competitive pricing, and consistent quality. With proven expertise and strict quality control, we are the trusted partner for global car and truck brands seeking reliable and efficient Plastic Mud Flap Mold and Mudguard Injection Mould solutions.

Besides, Kaihua's Car Led Combination Tail Lamp Plastic Injection Molding Molds and Automotive Glove Box Injection Mould have also earned extensive recognition within the sector.

2.Case Product Parameters

|

Product Name |

Mud Flap |

|

Plastic Material |

PP |

|

Injection Molding Machine Tonnage |

2400 |

|

Mold Material |

P20/1.2738/1.2738HH |

|

Number of Mold Cavities |

1+1 |

|

Hot Runner System |

YUDO 14-point Valve Gate |

|

Grain or Electroplate |

spray painting |

|

AutomaticDemolding Requirements |

Robot |

3.Product Display

4.Production details

5.Product feature and application

(1) Product feature

Kaihua Mud Flap of Plastic Injection Mould – Engineered for Precision and Durability

● High Durability – Manufactured with premium mold steel , Kaihua's Mud Flap Injection Mold ensures long service life and stable performance for continuous automotive production.

● Precision Fit – Advanced CNC machining guarantees accurate cavity dimensions and tight tolerances, allowing each Car Mud Flap Mold and Truck Mud Flap Mold to deliver a flawless parting line.

● Efficient Production – Optimized cooling and runner systems reduce cycle time while maintaining consistent quality, making the mould highly cost-effective for OEM programs.

● Customizable Options – Supports advanced molding processes, including gas-assisted molding and micro-foaming, to create lightweight yet impact-resistant Splash Guard Injection Mold solutions.

● Superior Surface Finish – The Plastic Mud Flap Mold achieves smooth, paint-ready surfaces directly from the mold, minimizing secondary finishing.

● Ease of Maintenance – Modular component design allows quick insert replacement and simplified servicing, reducing downtime and extending mould life.

●OEM Standard Compliance – Engineered in line with global automotive standards, ensuring reliability for both domestic and export markets.

● Long-Term Performance – Built to withstand high-volume production, each Mudguard Injection Mould delivers consistent results and repeatability over years of operation.

(2) Product application

● OEM Manufacturing – Widely adopted by automotive brands, our Mud Flap Injection Mold delivers accurate dimensions and reliable durability, ensuring consistent fit and performance in high-volume car and truck production.

● Aftermarket Replacement – Ideal for producing Car Mud Flap and Truck Mud Flap parts that match OEM specifications, providing protection, style, and safety in vehicle repair and customization markets.

● Global Market Supply – Designed to meet international automotive standards, Kaihua's Plastic Mud Flap Mold and Mudguard Injection Mould ensure stable quality for worldwide export and supply chains.

6. Prodect qualification

(1)Mud Flap of Plastic Injection Mold Trial Process

● Mold Preparation: Securely close the mold to ensure it is properly aligned and ready for injection.

● Material Loading: Introduce dried plastic pellets into the hopper of the injection molding machine.

● Melting Phase: Heat the injection unit to melt the plastic pellets uniformly.

● Injection Phase: Inject the molten plastic into the mold cavity using a precision injection system.

● Pressure Maintenance: Apply consistent pressure to ensure the mold cavity is fully filled and maintains its shape during the filling process.

● Cooling Phase: Allow the injected plastic to cool and solidify within the mold, taking on the desired shape.

● Ejection: Carefully open the mold and eject the finished plastic product.

(2) Product shipment and packaging photos

(3) Design review photos

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.