As competition tightens in automotive door panel manufacturing, quality and efficiency are core to enterprises standing out. As key production equipment, automotive door panel assembly injection molds directly impact manufacturers’ output and product quality. Specializing here, we support numerous door panel makers with full-process services covering design, manufacturing and after-sales, fueling industry high-quality development.

Precision Design Solves Manufacturing Pain Points

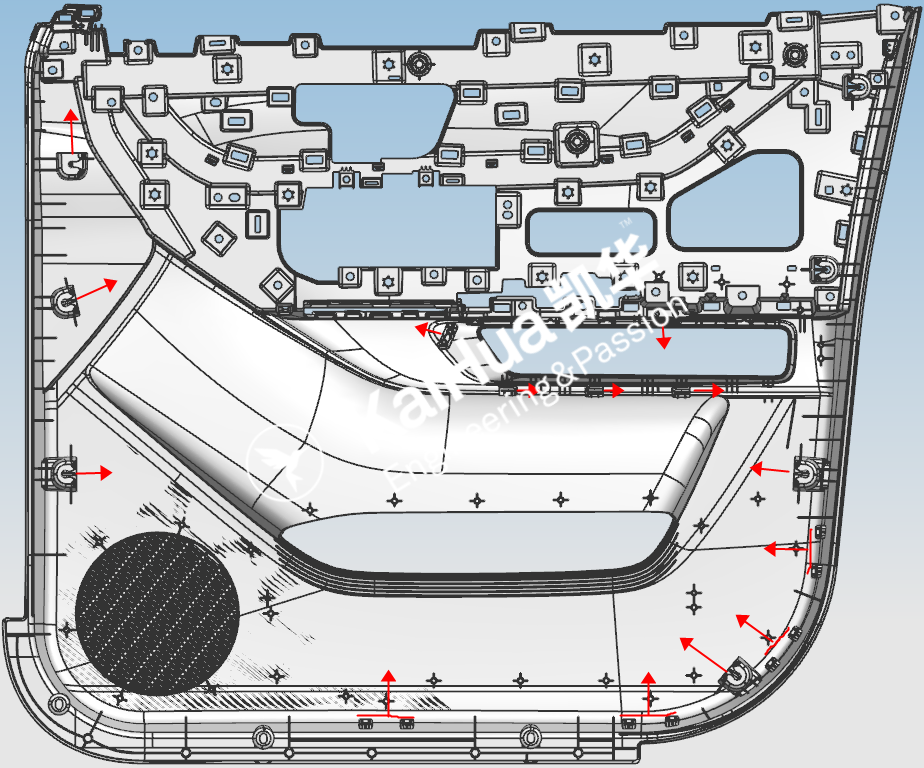

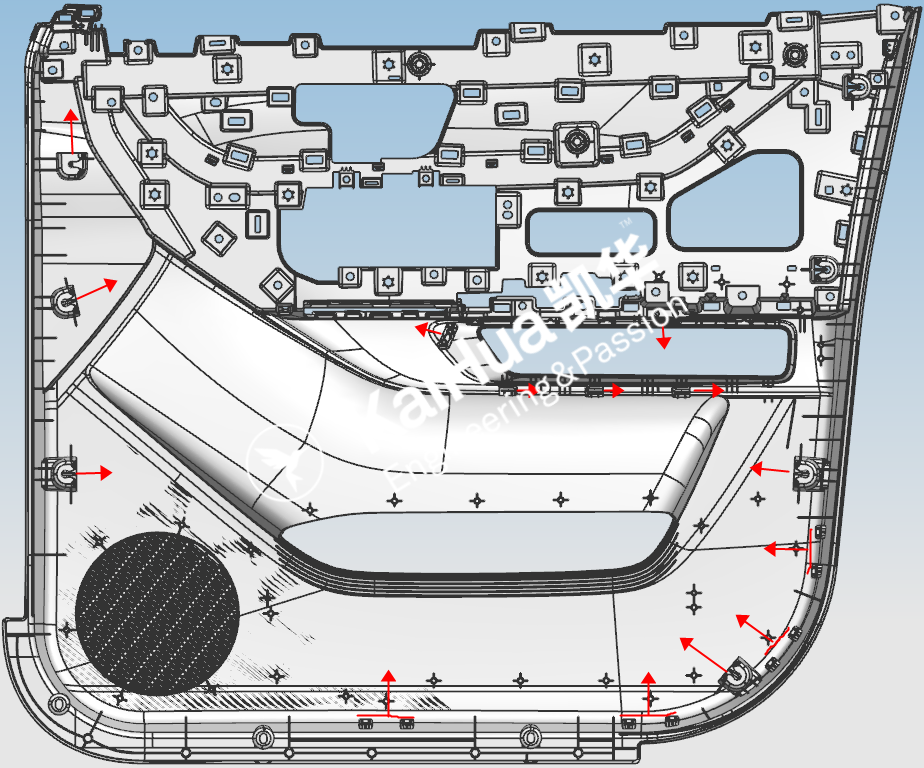

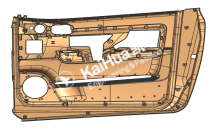

Automotive door panels include inner panels, outer panels and reinforcing ribs, with distinct strength, appearance and sound insulation needs across parts. Mainstream materials like PP+T20 glass fiber composite and ABS resin often face fiber exposure, uneven shrinkage and temperature sensitivity during processing.

Backed by a 200-strong design team, we use manufacturers’ 3D models to analyze structural defects via professional software, optimize key parameters, and deliver DFM reports with critical dimensional tolerances. We also fine-tune mold cavity roughness by material: Ra≤0.8μm for flawless appearance; hot runner and needle valve gates for large panels to avoid uneven melt flow. Combined with quality hot runners and precise temperature control, this cuts rejection rates. Our dedicated molds excel in material adaptability, meeting diverse needs.

Precision Manufacturing Ensures Stable Mass Production

Door panel manufacturing demands ultra-high precision—mounting hole tolerances must be strict to avoid misinstalling window regulators or audio systems. To meet this, we’ve invested in a precision workshop with high-end equipment such as Makino. Mold cavities use quality, specially treated steel for long-term mass production.

During mold testing, we pre-formulate injection parameter plans based on material and mass production targets, and record real-time data. For issues like flash or bubbles, we quickly solve and retest. On delivery, we provide a Mold Maintenance Manual, promise prompt fault responses and parts supply, and match injection machine parameters to needs. Our precision testing further guarantees mass production stability.

Full-Lifecycle Services Solidify Cooperation

We offer a “pre-consultation – mid-manufacturing – post-maintenance” system for door panel makers:

Pre-phase: Dedicated project managers handle needs, share weekly progress, and offer free design consultation and multi-scheme comparisons for those without 3D models.

Mid-manufacturing: Daily progress updates via exclusive client platforms with photos and videos, and quick technical collaboration meetings.

Post-maintenance: On-site training for operators and maintenance staff, free repairs, and lifelong maintenance.

We hold IATF 16949 and ISO 9001:2015 certifications; materials meet environmental standards, with full records archived. With over 1,500 door sets of panel molds under its belt, Kaihua Mould boasts extensive expertise in manufacturing stack molds! To learn more about stack mold door panels, please click “Stack Mold Door Panels” or reach out to our team for an online consultation—we’re here to help!

Focused on door panel manufacturers’ needs, we’re a reliable partner for boosting competitiveness, thanks to professional mold tech, precision manufacturing, and efficient full-lifecycle services. We continue driving stable, healthy development of the automotive door panel industry.

Post time: Sep-19-2025