OEM Manufacturer Room Dustbin - 360L Dustbin – KAIHUA

OEM Manufacturer Room Dustbin - 360L Dustbin – KAIHUA Detail:

360L Dustbin

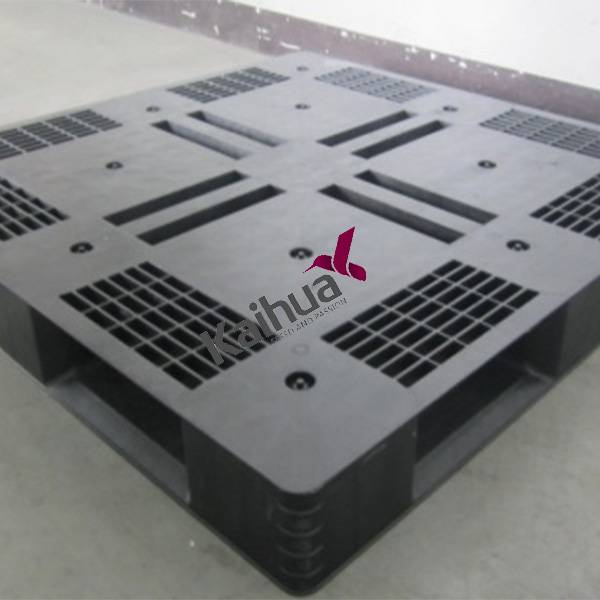

Part size: 867 X 751 X 1059 mm

Mold size : 1795X1695X1865 mm

Mold weight : 44345 kg

Machine : HT 3300T

Solution and mould making for dustbin, pallet, crate etc. Most of the moulds are exported to clients in Europe and America market. Currently we can supply large mould weighting up to 90T.

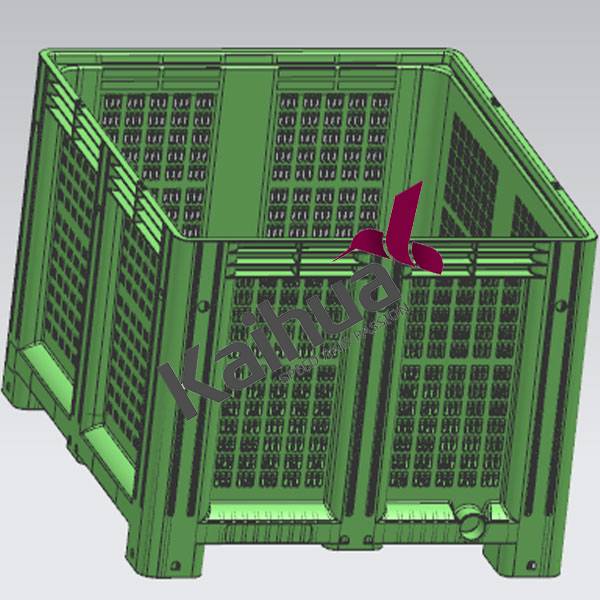

We are capable to make dustbin moulds range from 40L to 3200L. With rich experience we have obtained year by year, our moulds can have very fast cycle time and long mould life. We can provide moulding solutions for industrial crates as well as big agricultural crates. By deep study on how to change versions easily, we help our client to save mould and production cost. No matter small, easy handle pallet or clean, stable pallet for food, hygiene segment. Our moulds are always built with short cycle time as well as easily changeability. Meanwhile, we can provide service for dynamic and static loading analysis.

Logistics division has an average annual capacity of about 200 moulds, the maximum mold can reach 80T. We are good at providing the best solutions for testing standards( such as loading capacity), multi-version interchange and short molding cycle.

Technology Cases

1.Mucell:

The annual average is about 20 sets of cars, household appliances micro-foaming molds. Have the sbility to propose solutions to part design and mold design, and can complete the mold testing on 470t-3300t micro-foaming plastic injection machine.

Advantages: shorten molding cycle, improve dimensional accuracy, eliminate shrinkage of product surface, reduce clamping force and reduce product weight.

Representative customers: Benz, Volkswagen, Great Wall, ford, GEELY.

2.Stack mold technology:

The average annual is about 5-10 sets of stack molds for automobile and household products.

Advantage: reduce mold cost and production cost.

Representative customers: Audi, Ikea.

3.Gas-Assisted Injection Molding:

The annual average is about 20 sets of automobile, household necessities gas-assisted injection molds.

Advantage: reduce production cost, improve product appearance.

Representative customers: Jaguar Land Rover, RESOL.

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for OEM Manufacturer Room Dustbin - 360L Dustbin – KAIHUA , The product will supply to all over the world, such as: Hungary, Brisbane, Ghana, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.