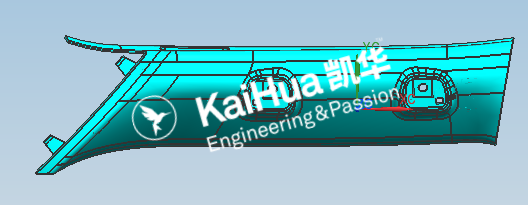

Pillar Car Part Mold Automobile Plastic Part Car Pillar Mould

1.Product Introduction

Kaihua's Automobile Plastic Part Car Pillar Mould belongs to the company's automotive interior system mould category, dedicated to manufacturing A-pillar, B-pillar, and C-pillar parts for vehicles. The product is developed to meet the needs of global automotive markets, serving not only Chinese national brands (SAIC, Geely, BYD) and joint-venture brands (FAW-Volkswagen, BBAC, Shanghai GM) but also international premium brands (McLaren, Tesla, Mercedes-Benz) and Tier 1 suppliers (Yanfeng, Faurecia, Magna).

To ensure durability and precision, the mould adopts premium materials: mold steels from Buderus (Germany), BAOSTEEL, and LKM; hot runners from global top brands like YUDO and Kyuventive; and standard parts from MISUMI (Japan) and HASCO (Europe). It is processed by top-tier 5-axis machining equipment (e.g., MAKINO, FIDIA, DMG), achieving an industry-leading tolerance to guarantee seamless compatibility with automotive assembly lines.

In addition, two of Kaihua's prominent Automobile Plastic Injection Molds—the Headlight Cover Mould-Double Color Mould and the Car door mould—have received wide praise in the industry.

2.Product Display

|

Product Name |

Automobile Plastic Part Car Pillar Mould |

|

Applicable Pillar Type |

A-pillar, B-pillar, C-pillar (customizable for sedans, SUVs, EVs) |

|

Compatible Plastic Materials |

PP, ABS, TPE, PC/ABS (meets automotive low-VOC requirements) |

|

Matching Injection Machine Tonnage |

470T - 1800T |

|

Number of Mold Cavities |

1 (standard); 2 (customizable for high-volume production) |

|

Mold Steel Material |

1.2344/1.2343,1.2738HH,1.2738,718H,P20HH,etc. |

|

Mold Steel Brand |

Buderus,Lurgi, Bohler,etc. |

|

Surface Treatment |

Grain (matte, glossy, or electroplated finish, customizable) |

|

Automatic Demolding |

Robot-compatible (integrated with automated automotive production lines) |

|

Hot Runner Brand |

YUDO, Kyuventive, INCOE etc. |

|

Service Cycle |

≥500,000 cycles |

3.Product Display

4.Production details

5.Product feature and application

(1) Product feature

● Ultra-High Precision: Supported by imported 5-axis CNC machines and CMM inspection, ensuring tight fit with automotive interior components.

● Long Lifespan: Premium steels and strict heat treatment process enable 500,000+ service cycles.

● Global Compatibility: Uses international standard parts (MISUMI, HASCO) and hot runners (YUDO), supported by Kaihua's global service network for fast replacement and maintenance.

(2) Product application

● Broad Customer Coverage: The moulds are widely used in EVs (BYD, Tesla), premium ICE vehicles (Mercedes-Benz, Volkswagen), and mainstream models (Great Wall, SAIC), adapting to different vehicle types and market demands.

● Automaker Types: EV brands (BYD, Tesla), premium ICE brands (Mercedes-Benz, Volkswagen), and mainstream brands (Great Wall, BAIC)—capable of producing substantial quantities of pillar parts every month.

● Industry Standards: Meets IATF 16949 automotive quality standards; finished parts comply with -40℃~80℃ heat resistance and impact resistance requirements.

6.Kaihua Service

● Global support network: Overseas offices in Germany, Portugal, USA, Brazil, Thailand cover key markets, enabling 8-hour rapid responses to technical issues, reducing cross-regional service delays.

● Post-sales training: Provides online/on-site training for client teams on mould operation, maintenance, helping avoid improper use and extend mould lifespan, complementing technical support.

● Kaihua’s after-sales network spans worldwide, with full second-stage service support in Europe, North America, Thailand, and Malaysia, etc.. Click to learn more about how Kaihua supports you after delivery.

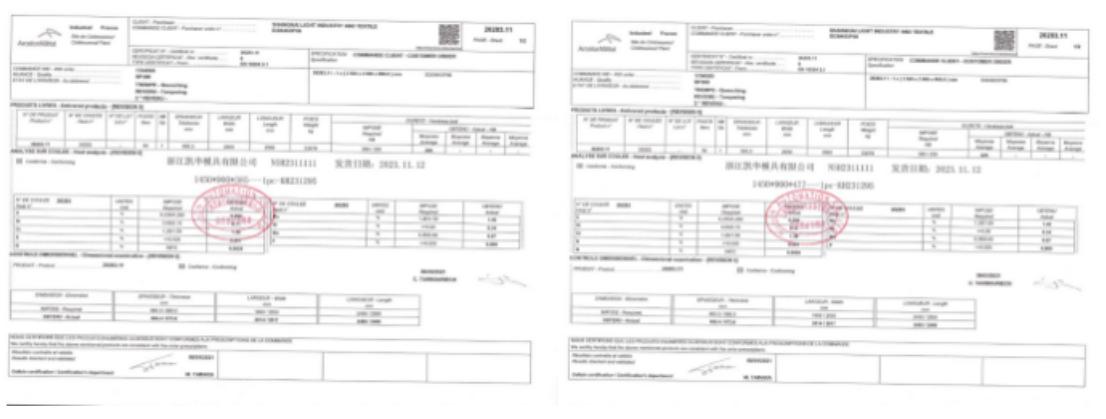

7.Product qualification

(1)Pillar Car Part Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing pillar car parts. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce pillar car parts that balance durability, structural integrity, and functional efficiency, suitable for a wide range of vehicle models.

(2)Product shipment and packaging photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here

8.Kaihua Mould Advantage

9.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.