Plastic Auto Car Handle Mold Automotive Handle Injection Mould Car Part Mold

1.Product Introduction

As a leading Automotive Mold Manufacturers, Kaihua Mould leverages deep expertise in Car Interior Mold engineering to solve core pain points in Automotive Handle Injection Mould production—delivering top-tier Plastic Auto Car Handle Molds for modern vehicles.

Common challenges in handle mold manufacturing (e.g., surface sink marks, inconsistent precision, poor material compatibility) are addressed head-on with our targeted technologies: We deploy imported multi-axis CNC machining (MAKINO models, up to 45,000 rpm) to eliminate dimensional errors, ensuring each Car Injection Molds For Internal Door Handle Plastic meets micron-level precision requirements. Our advanced mold flow analysis optimizes material flow in advance, avoiding sink marks and ensuring seamless compatibility with diverse high-performance plastics. Additionally, our modular mold design allows flexible adaptation to different vehicle models, while integration with KraussMaffei/Haitian injection machines guarantees stable production.

Backed by ISO 9001:2015 standards and a specialized engineering team, Kaihua Mould's Plastic Auto Handle Injection Mould solutions deliver durability, repeatability, and cost efficiency—trusted by automakers for reliable high-volume production.

In addition, two of Kaihua Mould's flagship Automobile Plastic Injection Molds – the Head Lamp Thick Wall Light Guide Injection Mould and Car Led Combination Tail Light Plastic Injection Molding Moldings – have earned broad recognition and acclaim across the automotive mould industry..

2.Product Display

|

Product Name |

Plastic Auto Handle Injection Mould |

|

Compatible Vehicle Types |

Compact cars / SUVs / MPVs |

|

Applicable Automakers |

Great Wall / Geely / SAIC / Volkswagen / Ford/etc. |

|

Cavity Number |

Single Cavity / Family Molds / Multi Cavity |

|

Part Material |

PP-EPDM /PP-T20 / customized |

|

Mold Steel Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Product Surface Requirement |

Texture (Gas-Assisted) /Grain/Customized |

|

Cold/Hot Runner |

Cold/Hot Runner |

|

Injection Molding Machine Tonnage |

160T / 250T/350T / Customized |

3.Product Display

|

Zhejiang Kaihua Moulds Co., Ltd. |

|||||

|

Speaker |

202 |

Air bag |

216 |

Handle |

196 |

|

Glove box |

420 |

Garnish license |

336 |

C-Pillar |

478 |

|

D-pillar |

520 |

Spoiler |

250 |

Door panel |

1550 |

|

Bumper |

1244 |

Backdoor |

286 |

Grill |

492 |

|

Mud guard |

500 |

Fog lamp |

216 |

Skirt |

381 |

|

Instrument Panel |

1500 |

Sunroof |

30 |

Etc. |

|

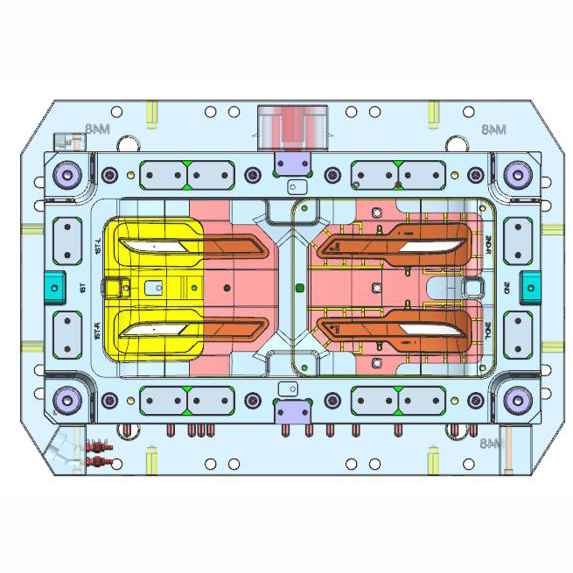

4.Production details

5.Product feature and application

(1) Product feature

● Proactive Pre-Design Analysis & Guidance: For every Plastic Auto Car Handle Mold project, our engineering team provides tailored pre-design analysis. Leveraging professional mold flow simulation tools, we predict and resolve potential issues in advance. Such as uneven material filling or structural weak points in Car Grab Handle Mold or Car Injection Molds For Internal Door Handle Plastic. This guidance ensures the mold design aligns with the customer's vehicle model needs and production goals, shortening the development cycle and reducing rework costs.

● Stable Compatibility for High-Volume Production: Our Plastic Auto Handle Injection Mould integrates seamlessly with mainstream injection machines. We use equipment like KraussMaffei KM series and Haitian JU/MA series for large-scale automotive mold projects, and the mold is designed to match these machines perfectly. Combined with advanced mold flow analysis, it optimizes material flow for automotive-grade plastics, guaranteeing consistent production for Car Interior Mold and Car Part Mold needs.

● Durable Build for Long-Term Use: The mold base of our Automotive Plastic Car Handle Mold uses high-grade steel from trusted suppliers such as LKM and Buderus. This material choice aligns with our quality standards for automotive molds, enabling the mold to resist wear even after extensive cycles. It reduces maintenance costs while maintaining stable performance for Interior Automotive Mold applications.

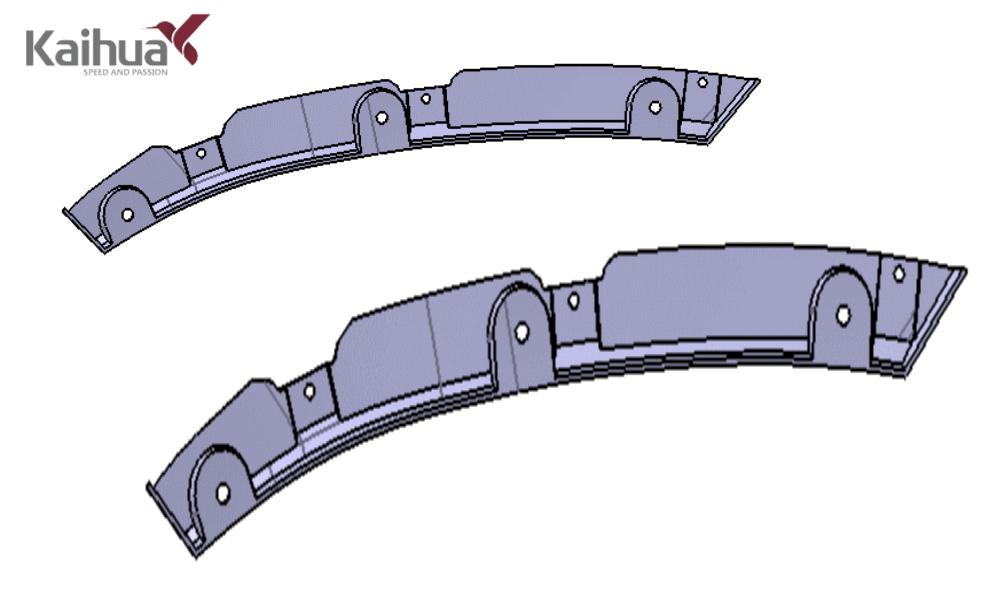

(2) Product application

● For Passenger Car Interiors

The Plastic Auto Car Handle Mold supports mass production of grab handles and inner door handles. It is compatible with compact cars, SUVs, MPVs and meets the production standards of automakers which including domestic leaders like Great Wall, Geely, and SAIC, as well as international giants such as Volkswagen, Ford, BMW, and BENZ. .

● Integrated Interior Manufacturing

This mold can be applied together with our Car Interior Mold series, including instrument panel and door panel molds. Unified precision and process control ensure accurate fit, reduce assembly errors and improve efficiency in vehicle interior production.

● Durability and Global Support

Using high-grade steel and precision machining, the mold produces handle components with strong durability, anti-aging and impact resistance, suitable for family cars, taxis and ride-hailing vehicles. With service centers in Germany, Brazil, India and other regions, Kaihua provides fast response and localized support for global customers.

● Contact Kaihua today to explore customized automotive mold solutions for your projects.

6.Kaihua Service

● As a customer-focused Automotive Mold Manufacturer, Kaihua Mould provides end-to-end service to ensure a smooth experience throughout your Plastic Auto Car Handle Mold project, from initial consultation to long-term support.

● Our engineering team offers tailored pre-project guidance, including pre-design analysis for Car Grab Handle Molds, Inner Door Handle Injection Molds, and other Interior Automotive Mold solutions. With mold flow simulation, we align designs with vehicle models and production goals. For global clients, our offices in Germany, Brazil, India, Spain, and the USA enable localized communication and quick response to regional standards or technical requirements.

● After delivery, we continue to support your production with operator training, timely replacement of wear parts from trusted suppliers like LKM, and regular follow-ups to ensure stable performance of your Car Part Molds. Backed by ISO 9001:2015-certified processes, Kaihua helps reduce downtime, lower costs, and keep your Car Interior Mold manufacturing efficient and reliable. Click to learn more about how Kaihua supports you after delivery.

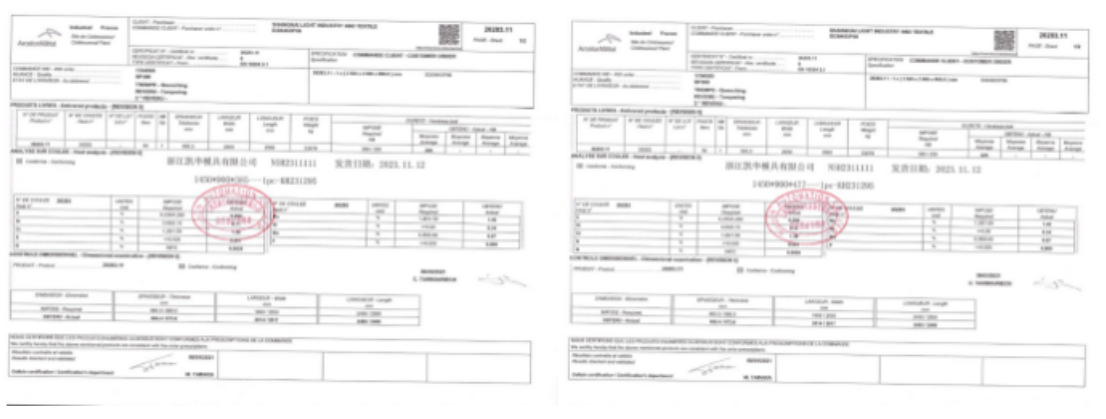

7.Product qualification

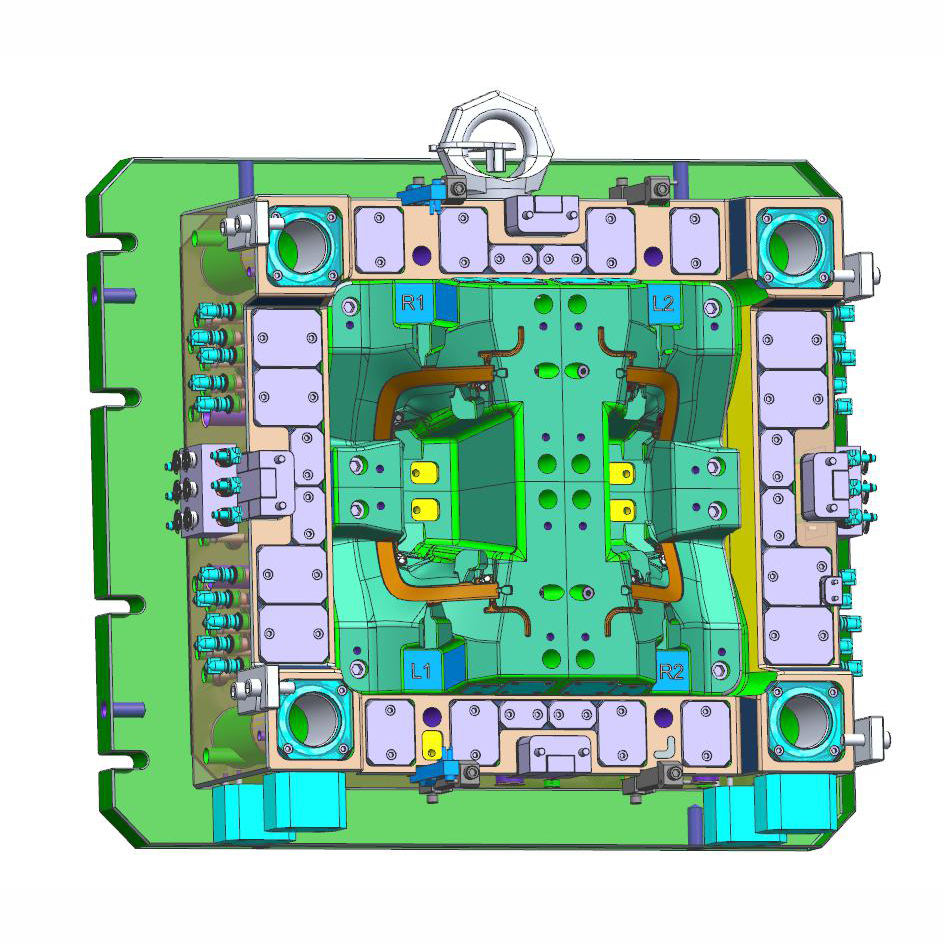

(1) Automotive Handle Injection Mould Trial Process

Kaihua conducts a rigorous trial molding process for every Automotive Handle Injection Mould to ensure optimal performance before mass production. During the trial, we test mold flow, injection parameters, and cooling efficiency to verify stability and repeatability under high-volume conditions. Each sample part is inspected for dimensional accuracy, surface finish, and structural strength, confirming that the handle components meet durability, functional, and aesthetic requirements. This process guarantees that the mould can deliver consistent quality across different vehicle models while supporting the efficiency of large-scale automotive interior production.

(2) Product shipment and packaging photos

(3) Design review photos

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.