Plastic Spoiler Injection Mould car Parts Mold OEM

1.Product Introduction

Kaihua Mould has earned a strong reputation in automotive spoiler mould manufacturing, delivering reliable and precise solutions for car exterior components. With over 20 years of automotive expertise, we provide plastic spoiler injection moulds trusted by global automakers.

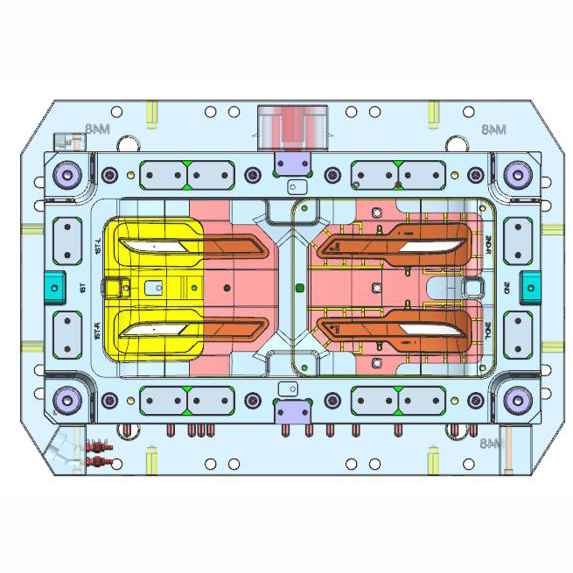

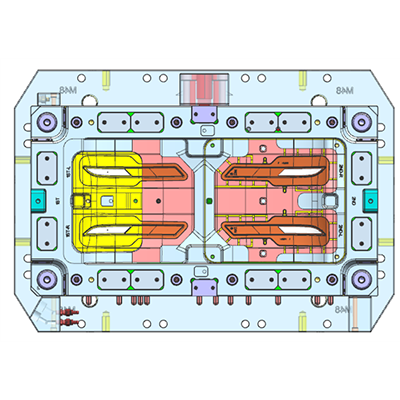

Using advanced CAD/CAM design and Moldflow simulation, our car spoiler moulds—from standard to custom lip spoiler moulds—meet strict OEM standards for aerodynamics and appearance.

We build each mould with premium materials like German 2738 steel to ensure high durability, stability, and lower maintenance in mass production.

As a professional automotive mold maker, Kaihua offers full OEM/ODM services, supported by 5-axis machining and an experienced engineering team. From design to delivery, we provide efficient, high-quality automotive spoiler mould and car exterior mould solutions for global clients.

In addition, Kaihua's Auto Airbag Mould and Car Pillar Mould stand out in the industry, celebrated for their precision engineering and proven performance.

2.Product Display

|

Product Name |

Spoiler Mold |

| Plastic Material | LDPE+EVA, PP+EPDM-T10, TPV, PPTD20, PC/ABS, PMMA (UV-stabil), PMMA+ASA, Customized |

| Injection Molding Machine Tonnage | 480T, 530T, 650T, 700T, 800T, 1000T, 1200T, 1300T, Customized |

| Number of Mold Cavities | 1, 1*1, 1+1, 2, 2+2, Customized |

| Mold Material | 1.2344/1.2343,1.2738HH,1.2738,718H,P20HH,etc. |

| Mold Steel Brand | Buderus, Bohler, Gröditz, Finkl, etc. |

| Grain/Finish | Grain (matte, glossy, or electroplated finish, customizable) |

| Hot Runner Brand | YUDO, Synventive, Mold-Masters, HRS, INCOE, Customized |

3.Production details

|

Zhejiang Kaihua Mould Co., Ltd. |

|||||

|

Speaker |

202 |

Air bag |

216 |

Handle |

196 |

|

Glove box |

420 |

Garnish license |

336 |

C-Pillar |

478 |

|

D-pillar |

520 |

Spoiler |

250 |

Door panel |

1550 |

|

Bumper |

1244 |

Backdoor |

286 |

Grill |

492 |

|

Mud guard |

500 |

Fog lamp |

216 |

Skirt |

381 |

|

Instrument Panel |

1500 |

Sunroof |

30 |

Etc. |

|

4.Product feature and application

(1) Product feature

● Aerodynamic Precision

Kaihua's Plastic Spoiler Injection Moulds deliver high dimensional accuracy for complex curved surfaces—reducing air resistance, minimizing wind noise, and improving vehicle stability. From lip spoiler moulds for sedans to robust designs for SUVs, every mould meets OEM aerodynamic and surface-fit standards.

● Engineering Excellence

Using Moldflow simulation and premium materials such as German 2738 steel, our plastic car spoiler moulds maintain strength and dimensional stability under demanding production conditions. Reinforced mould bases and optimized cooling systems help reduce maintenance costs and extend tool life.

● Production Efficiency

Designed with multi-cavity layouts and compatible with 160T–5500T injection machines, Kaihua's spoiler moulds enable fast, stable, and efficient production. Supported by MAKINO graphite automation lines, we achieve short T1 lead times, ensuring rapid project turnaround for car exterior mould applications.

● Quality Assurance

Every plastic automobile spoiler mould is carefully inspected using WENZEL and HEXAGON 3D CMM systems to ensure it meets IATF 16949 quality standards. Real-world examples—like the Audi A3 mould, which achieved a defect rate of less than 0.5%—demonstrate our consistent quality and reliability.

● Global Support

As a leading automotive mold maker, Kaihua offers comprehensive support—from DFM optimization and car parts mould integration to global after-sales service across 15 international branches. We ensure smooth and reliable production launches for both OEM custom projects and ODM mass-production programs.

(2) Product application

● Kaihua Mold's Plastic Spoiler Injection Mould centers on flexible customization, adapting to diverse spoiler designs and vehicle needs. For premium models requiring sleek curves (like lip spoiler Mould), we usually tailor YUDO valve-type hot runners with custom injection point layouts to match unique cavity shapes; for rugged vehicles needing durable ABS automobile Spoiler Mould, we adjust mold steel thickness and surface treatment to align with impact-resistance demands. No matter the spoiler style—from sporty to utilitarian—our automotive Spoiler Mould is engineered to fit your exact design specs.

● Our plastic car Spoiler Mold is customized for material compatibility, matching your chosen plastic perfectly. For soft PP (used in budget models), we polish the cavity smoother to prevent sticking—this targeted tuning means our Spoiler Plastic Mould works seamlessly with your preferred material, no one-size-fits-all flaws.

● When it comes to production adaptability, our plastic automobile Spoiler Mould offers custom modular designs. For clients needing to switch between multiple spoiler variants, we create quick-change core inserts that fit existing mold frames—no need for full mold replacements. We also pre-design inspection benchmarks aligned with your quality check processes, making it easier to integrate the mold into your production line. This flexibility makes us a go-to Automotive Mold Maker for brands with varied customization needs.

● Even maintenance of our Car Parts Mold (including automotive Spoiler Mould) is designed to your needs. We design inspection ports and access points according to your team's maintenance habits—be it regular hot runner checks or easy cooling channel upkeep. This alignment with your workflow reduces downtime and keeps customization-driven production on track.

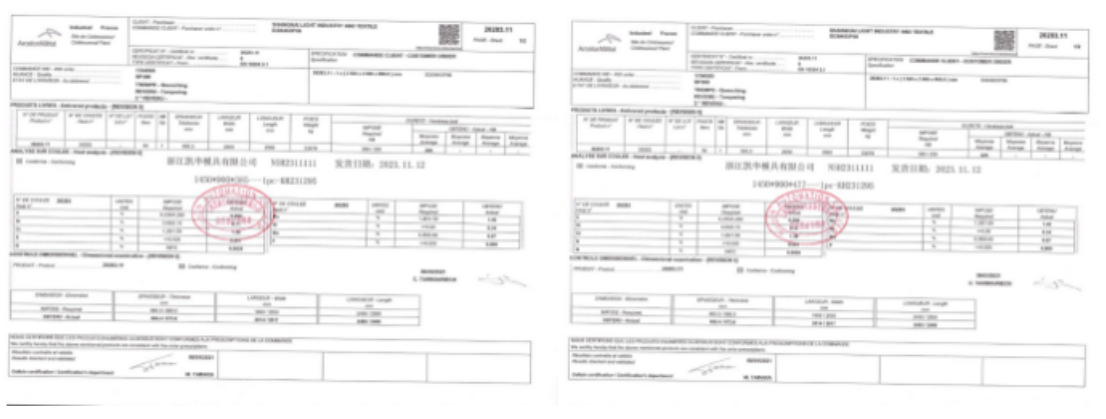

5.Product qualification

(1)Car Spoiler Injection Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing vehicle spoiler. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce air grilles that balance durability, visual appeal, and functional efficiency, suitable for a wide range of vehicle models.

(2)Product shipment and packaging photos

(3) Design review photos

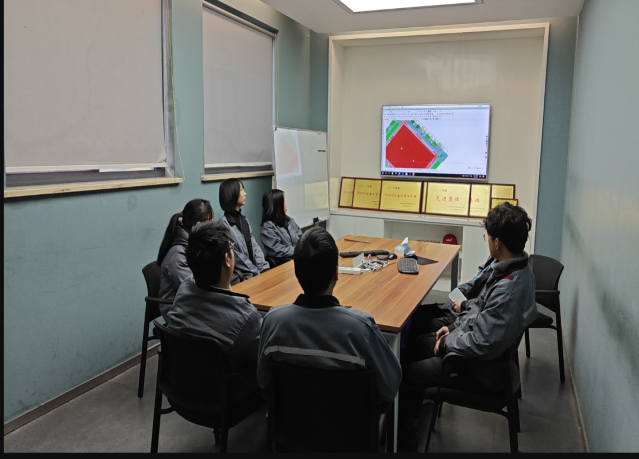

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

6.Kaihua Mould Advantage

9.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.