Renewable Design for Impact Molding - Automotive Division – KAIHUA

Renewable Design for Impact Molding - Automotive Division – KAIHUA Detail:

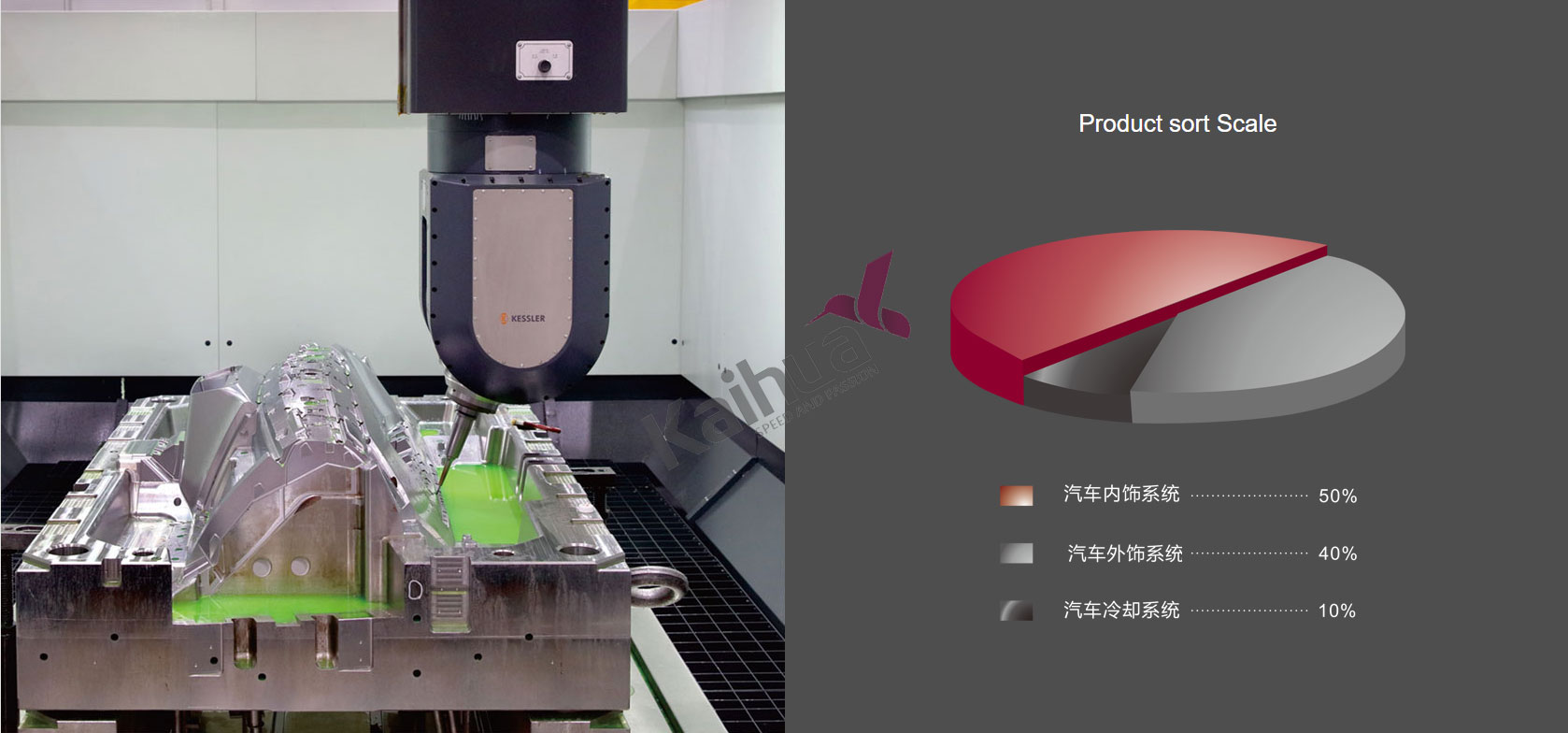

Solution and mould making for auto exterior system such as bumpers, grille, mud guard etc; interior system such as instrument panel, door panel, pillar etc; Cooling system such as shround, fan, water tank etc.

The company is supporting the world-renowned automobile OEMs such as McLaren and other sports cars and Tesla, as well as German, French, Japanese, and American. It also originates from China for SAIC, Geely, Great Wall, Guangzhou Automobile, BYD, etc. The global Chinese automobile brands are joint venture brands such as FAW-Volkswagen, Beijing Benz, Shanghai GM, Dongfeng Nissan, Dongfeng Renault and Shenlong Automobile, and are first-tier suppliers such as Faurecia, Pio, Yanfeng, Echi, Magna and so on. Matching.

●Global OEM:

●Domestic:

●Joint Venture:

●First Grade Supplier:

Advantage: reduce mold cost and production cost.

Who Are We

Kaihua workers adhere to the “people-oriented, win by quality, continuous innovation, sustainable management” business philosophy, strictly control “quality, time and cost”, all take the customer as the center. Kaihua is committed to become a superb mould supplier in worldwide.

Huangyan base covers an area of 40,000 square meters, with over 500 employees and manufacturing around 1,500 molds per year. It has Logistics division, Automotive division, Household division, Appliance and Medical division, specialized in the manufacture of dust bins, pallets, outdoor tables and chairs, crates, storage boxes, air conditioners, refrigerators and other molds. 80% of the molds are sold abroad, mainly including GARDENLIFE, GRACIOUSLIVING, RIMAX, SMARTFLOW, MAOROPLASTICS, STARPLAST, etc. Auto moulds are mainly for GM, Great Wall Automobile, SAIC, NAC, Geely Automobile, Tianjin FAW, Haima Automobile and other independent brands. 60% of the molds are exported to more than 60 countries or regions such as Europe, North America, South America, Asia, etc.

Sanmen base covers an area of 36,000 square meters with over 350 employees, and produces over 600 sets of molds annually. It is specialized in plastic injection moulds for automobile parts like automobile bumpers, fences, lamps and other exteriors system parts; automobile dashboard, door panel and other interior decoration system parts; wind frame, wind blade, flume and other cooling system parts. It mainly provide moulds and services to well-know automobile brands such as GM, FORD, VW, BMW, BENZ, Peugeot, RENAULT, Magna, FIAT, VOLVO, NISSAN, TOYOTA, and well-known automobile enterprises such as IAC, PO, Faurecia, Viston, BOSCH, BEHR, Valeo and Denso. 70% of the moulds are exported to more than 30 countries or regions such as Europe, North America, South America, Asia and etc.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for Renewable Design for Impact Molding - Automotive Division – KAIHUA , The product will supply to all over the world, such as: Roman, Luxemburg, Slovakia, Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

We have been looking for a professional and responsible supplier, and now we find it.