Sedan Plastic Bumper Injection Mold

1.Product Introduction

At Kaihua Mould, our focus lies in Sedan Plastic Bumper Injection Mold—each crafted with high-strength alloy frames and wear-resistant cavity inserts, built to endure extensive injection cycles. Backed by decades of mastery, we merge thoughtful engineering with smart manufacturing, earning trust from automakers worldwide.

Our standout Sedan Plastic Bumper Injection Mould features modular core designs, enabling swift adjustments for different sedan models. Every Bumper injection mold undergoes thorough inspections, ensuring consistent dimensional quality, whether it’s an OEM Sedan Bumper mould or a custom Plastic Bumper injection mold.

Equipped with self-cleaning runners and temperature-regulating channels, our Auto Bumper injection mould and Car Bumper injection molding reduce material waste while maintaining stable flow. This makes the Injection Mould for Automotive Bumper ideal for efficient mass production.

From mold designs tailored to specific sedan curves to quick-wear part replacement services, Kaihua guarantees warranty coverage, on-time delivery, and technical support. Choose us for durable molds, flexible solutions, and a reliable production partner.

Besides, Kaihua’s Car Pillar Mould Automobile Plastic Injection Mold and Car Door Panel Injection Mould with Gas Assistance Technology have also received widespread acclaim within the industry.

2.Case Product Parameters

|

Product Name |

Sedan Plastic Bumper Injection Mold |

|

Plastic material |

PP+EPDM-T20 |

|

Product weight (g) |

2600 |

|

Product size |

1939X560X474 |

|

Product wall thickness(mm) |

2.8 |

|

Mold weight(t) |

29.9 |

|

Mold size |

2900*1500*1712 |

|

Injection molding machine tonnage |

2500 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

spray painting |

|

Automatic demolding requirements |

Robot |

|

Product Name |

Sedan Plastic Bumper Injection Mold |

|

Plastic material |

PP+EPDM-T20 |

|

Product weight (g) |

3140 |

|

Product size |

1865X388X420 |

|

Product wall thickness(mm) |

2.8 |

|

Mold weight(t) |

22.9 |

|

Mold size |

2700*1400*1560 |

|

Injection molding machine tonnage |

2500 |

|

Number of mold cavities |

1 |

|

Grain or electroplate |

Grain |

|

Automatic demolding requirements |

Robot |

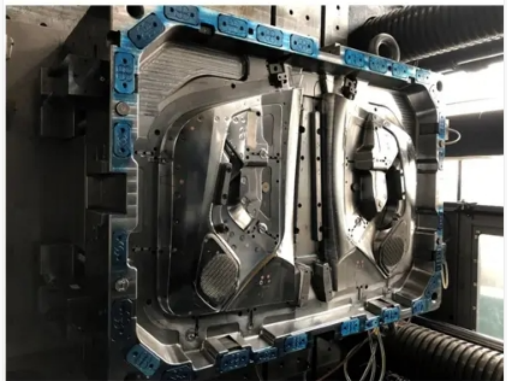

3.Product Display

4.Production details

5.Product feature and application

(1) Product feature

● Contour-Matching Cavity Design – Kaihua’s Sedan Plastic Bumper Injection Mold features a cavity precisely shaped to replicate sedan bumper contours, ensuring each molded part aligns with vehicle body lines.

● Material Flow Regulation – The Bumper injection mold is equipped with optimized runner systems that control plastic flow, adapting to different material viscosities for consistent filling of complex bumper shapes.

● Durable Component Construction – The Auto Bumper Injection Mould uses hardened steel cores and wear-resistant platens, standing up to the rigors of high-volume production cycles.

● Thermal Management System – The Car Bumper injection molding integrates evenly distributed cooling channels, maintaining stable temperatures to prevent part distortion during the molding process.

● Ejection Precision Setup – The Plastic Bumper Injection Mold features a synchronized ejection system that gently removes finished bumpers, avoiding damage to delicate edges or textured surfaces.

(2)Product application

● Aiding Post-Launch Design Tweaks

For sedans already in production, the Sedan Bumper Injection Mould allows for efficient updates to bumper designs. This helps automakers respond quickly to market feedback without disrupting main production lines.

● Enabling Cross-Brand Component Sharing

The Auto Bumper Injection Mould can be calibrated to produce bumpers compatible with multiple brands under the same automotive group, streamlining parts supply and reducing manufacturing costs.

● Boosting Mass Production Efficiency

The Plastic Bumper Injection Mold is engineered for high-speed, continuous operation, minimizing downtime between cycles. It ensures stable output even in large-scale production, meeting the high-volume demands of major automakers.

● Ensuring Compliance with Global Standards

The Injection Mould for Automotive Bumper is designed to meet diverse international safety and quality regulations, helping automakers seamlessly enter global markets without redesigning molds for different regions.

6. Prodect qualification

(1) Sedan Plastic Bumper Injection Mold Trial Process

● Mold Preparation: Securely close the mold to ensure it is properly aligned and ready for injection.

● Material Loading: Introduce dried plastic pellets into the hopper of the injection molding machine.

● Melting Phase: Heat the injection unit to melt the plastic pellets uniformly.

● Injection Phase: Inject the molten plastic into the mold cavity using a precision injection system.

● Pressure Maintenance: Apply consistent pressure to ensure the mold cavity is fully filled and maintains its shape during the filling process.

● Cooling Phase: Allow the injected plastic to cool and solidify within the mold, taking on the desired shape.

● Ejection: Carefully open the mold and eject the finished plastic product.

(2) Product shipment and packaging photos

(3) Design review photos

(4) Photos of the Technical Department Meeting

(5) Certificate

To learn more about Kaihua's certificates, please click here

7.Kaihua Mould Advantage

8.FAQ

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.