Car Dashboard Injection Mold with Kaihua Mucell Mould Technology

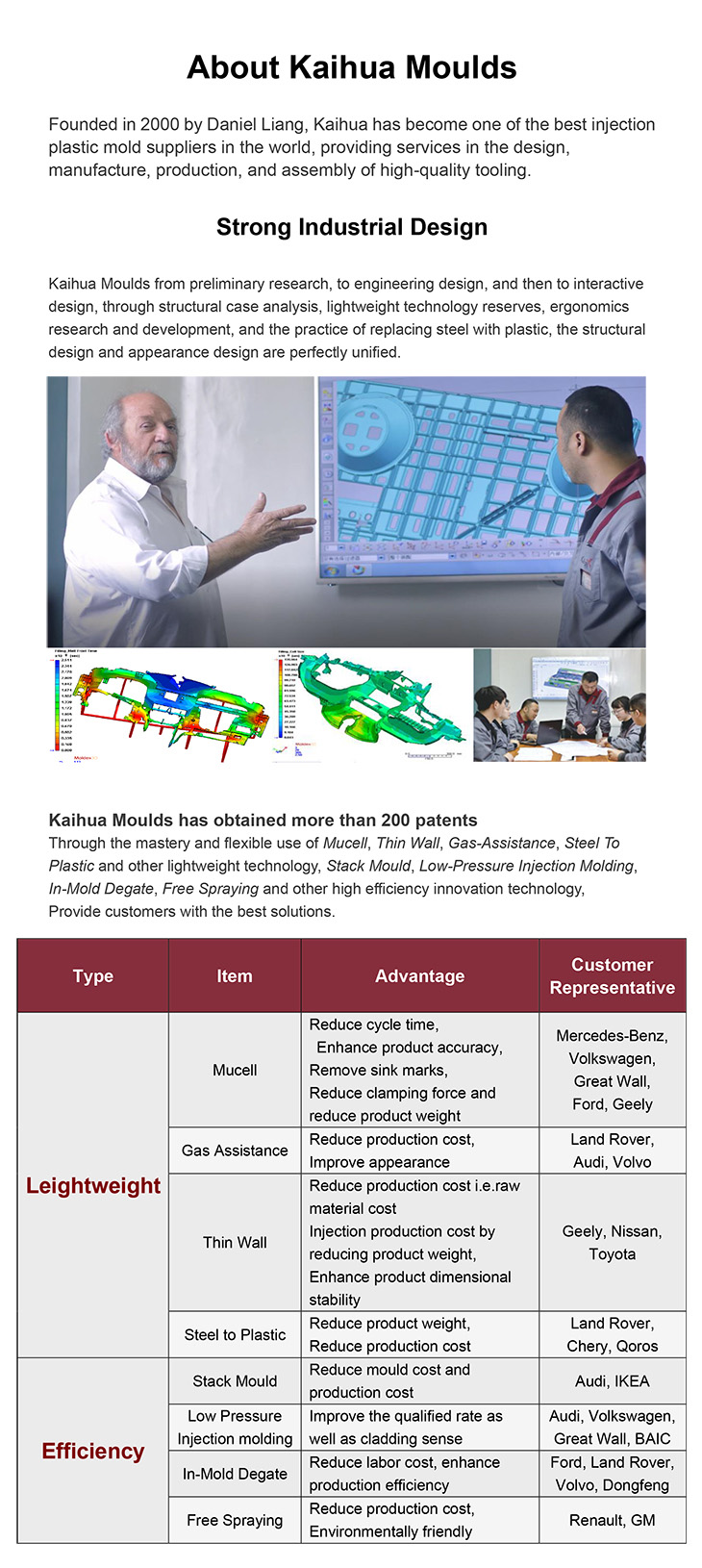

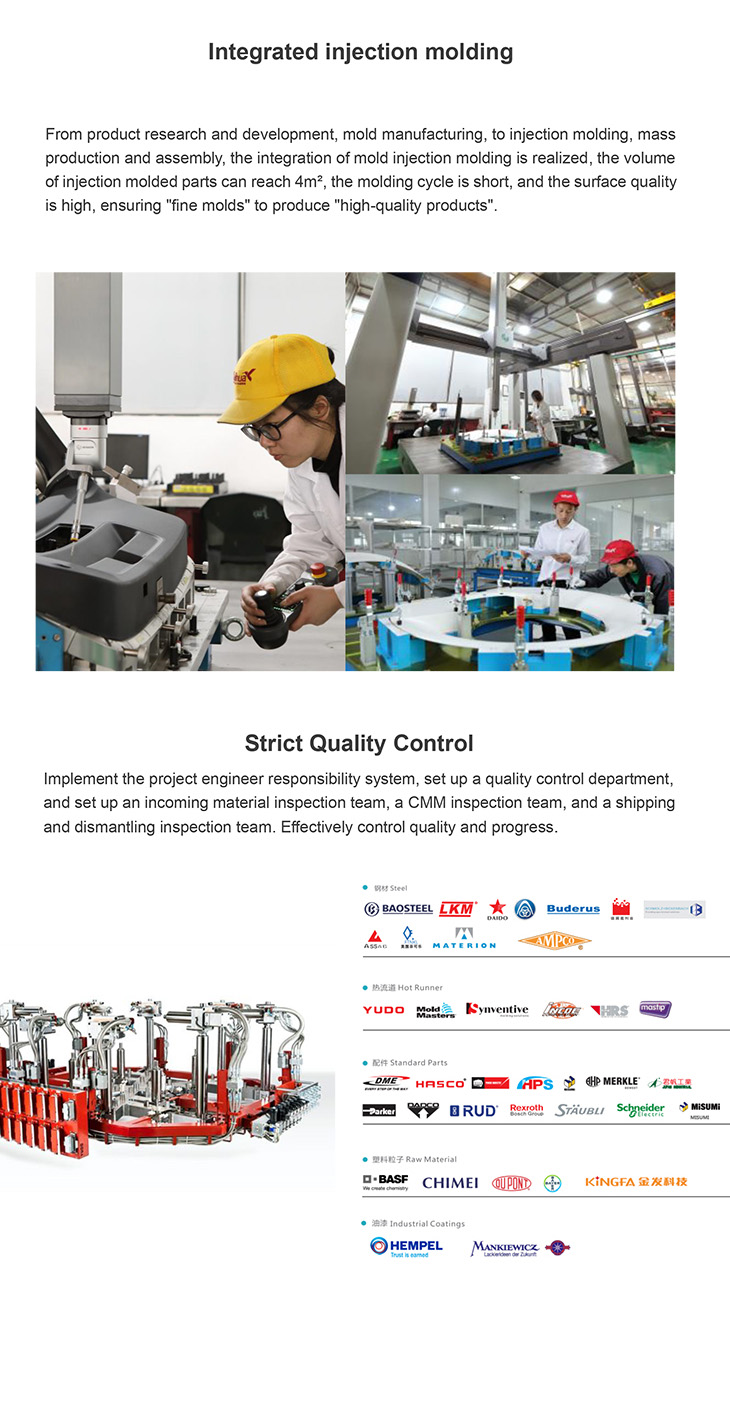

Kaihua Mould is a company that specializes in manufacturing a wide range of automotive moulds. We take pride in our high-quality products, which are designed to meet all of our client's requirements. Our focus on innovation and precision manufacturing technology has led us to develop the Mucell Mould Technology, which is ideal for car dashboard injection moulds.

The Car Dashboard Injection Mold with Kaihua Mucell Mould Technology is the result of years of research and development. It enhances part quality and reduces material usage. The Mucell technology results in a much better surface finish, which means less finishing work needed after production.

One of the main advantages of Kaihua's Car Dashboard Injection Mold is its ability to offer the highest levels of precision. The use of the Mucell process enhances the precision of the final product, especially for complex geometry parts. The lightweight properties of the parts, coupled with increased component strength, make the new material composition ideal for car dashboards.

Our team of skilled engineers and designers works tirelessly to ensure we achieve the complex geometric requirements of our clients. The Car Dashboard Injection Mold with Kaihua Mucell Mould Technology is the perfect fit for modern car models, helping automakers keep pace with the latest market trends while providing affordable products to consumers.

Another advantage is that our mould technology is environmentally friendly. The Mucell method reduces the amount of raw materials needed, and the lightweight parts created have a lower environmental impact. The reduction in weight also means that cars are more fuel-efficient, making this technology ideal for electric and hybrid vehicles.

In summary, the Kaihua Mould Car Dashboard Injection Mold with Mucell technology offers many advantages and is the perfect solution for companies that want to remain competitive and remain at the forefront of technological advances in the automotive industry. The parts produced with this technology are strong, lightweight, and provide incredible accuracy, making them ideal for a wide range of automotive applications. Contact us today to learn more about our Car Dashboard Injection Mold with Kaihua Mucell Mould Technology.

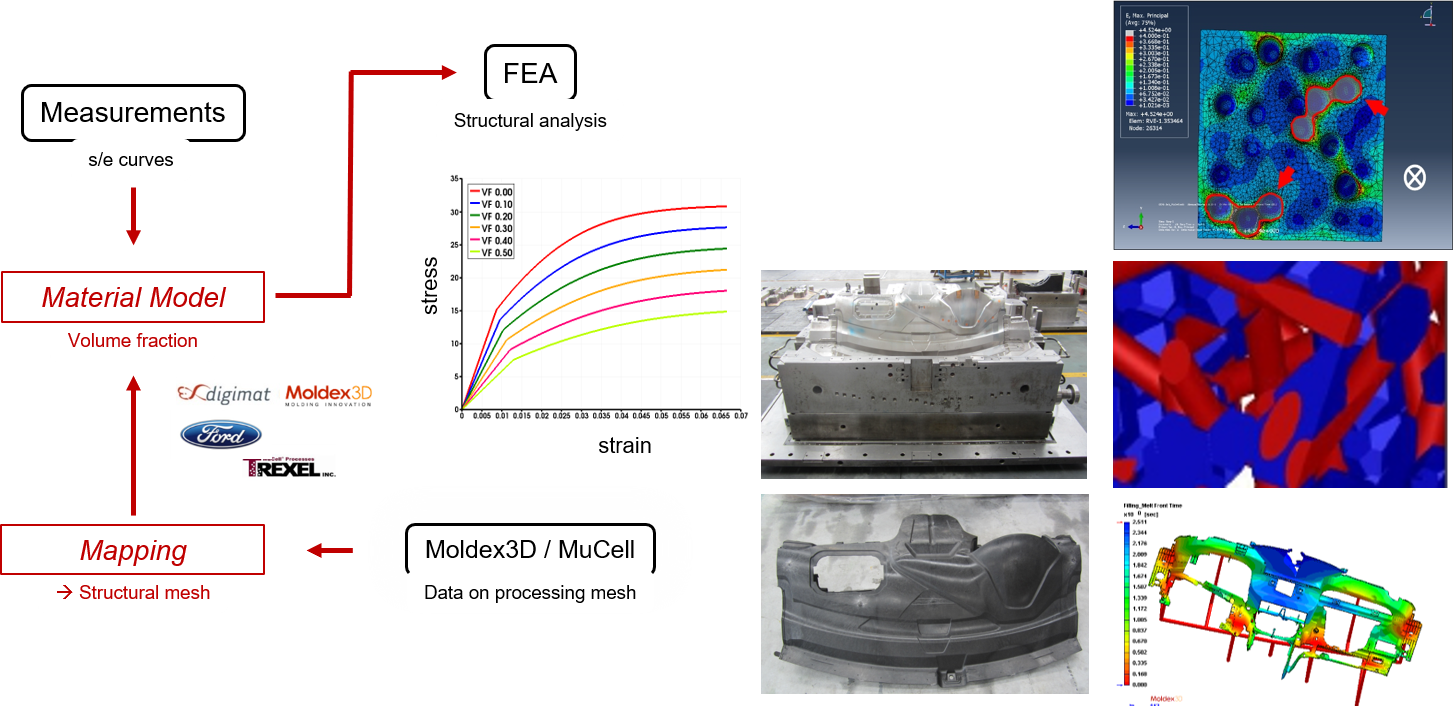

MuCell : Shorten forming cycle, Improve dimensional accuracy, Reduce volume shrinkage, Reduce clamping force, Reduce product weight (lightweight).

Limitations of Traditional Injection Molding

1.Dimensional accuracy is difficult to control

Uneven volume shrinkage of plastics after cooling

Warpage caused by uneven volume shrinkage

2.Difficult to reduce product cost

Sufficient clamping force is required for filling and pressure maintaining

Traditional molding process is not easy to save plastic

3.Difficult to optimize forming cycle

Improve volume shrinkage and increase holding time

Increase cooling time to improve deformation

Advantages of MuCell Technology

1.Greatly improve dimensional accuracy

2.Greatly reduce clamping cost

3.Greatly shorten the forming cycle