High Performance Rim Injection Molding - Medical Division – KAIHUA

High Performance Rim Injection Molding - Medical Division – KAIHUA Detail:

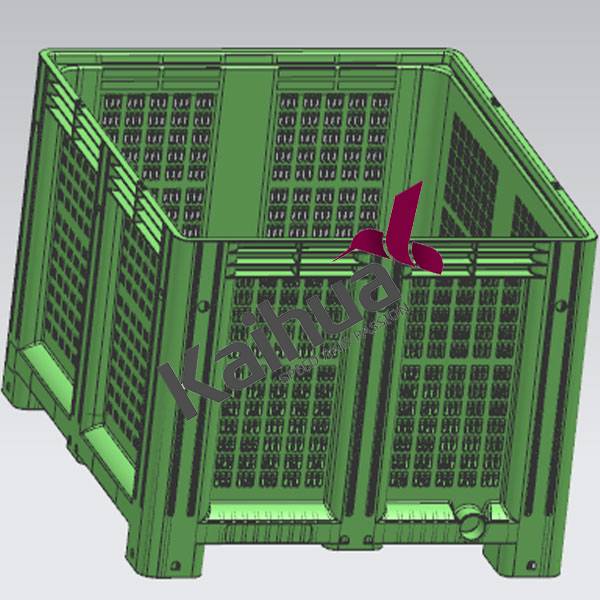

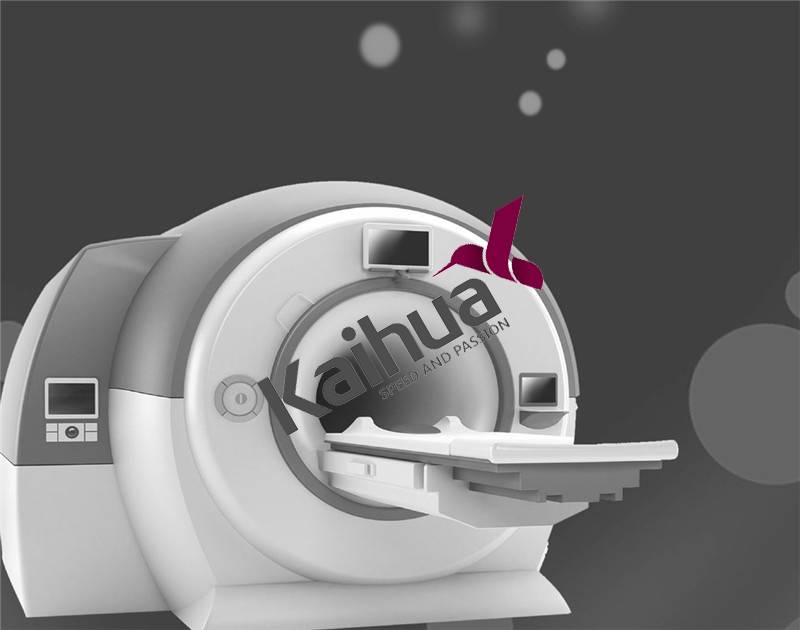

Solution and mould making for large medical equipment, fitness equipment such as MRI, CT and treadmill etc.

our advantages

High Quality (Mold & Product Quality)

On-time delivery (Approval Sample & Mould Delivery)

Cost Control (Direct & Indirect Cost)

Best Service (Service to Customer, Employee & Supplier)

System— U8 ERP management system

Routine—Project Engineering Control

Document—ISO9001-2008

Standardization—Performance Assessment Syste

Kaihua workers adhere to the “people-oriented, win by quality, continuous innovation, sustainable management” business philosophy, strictly control “quality, time and cost”, all take the customer as the center. Kaihua is committed to become a superb mould supplier in worldwide.

Huangyan base covers an area of 40,000 square meters, with over 500 employees and manufacturing around 1,500 molds per year. It has Logistics division, Automotive division, Household division, Appliance and Medical division, specialized in the manufacture of dust bins, pallets, outdoor tables and chairs, crates, storage boxes, air conditioners, refrigerators and other molds. 80% of the molds are sold abroad, mainly including GARDENLIFE, GRACIOUSLIVING, RIMAX, SMARTFLOW, MAOROPLASTICS, STARPLAST, etc. Auto moulds are mainly for GM, Great Wall Automobile, SAIC, NAC, Geely Automobile, Tianjin FAW, Haima Automobile and other independent brands. 60% of the molds are exported to more than 60 countries or regions such as Europe, North America, South America, Asia, etc.

Stack mold technology:

The average annual is about 5-10 sets of stack molds for automobile and household products.

Advantage: reduce mold cost and production cost.

Representative customers: Audi, Ikea.

Gas-Assisted Injection Molding:

The annual average is about 20 sets of automobile, household necessities gas-assisted injection molds.

Advantage: reduce production cost, improve product appearance.

Representative customers: Jaguar Land Rover, RESOL.

Low pressure injection molding:

The annual average is about 5 sets of low pressure injection mold.

Advantages: improve product level and appearance quality.

Representative customer: BAIC.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Performance Rim Injection Molding - Medical Division – KAIHUA , The product will supply to all over the world, such as: Australia, Moscow, Greek, We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.