I. Introduction

The rapid development of science and technology has made plastic products increasingly widely used in many fields. In the automotive industry, plastic products play a significant role in reducing vehicle weight and improving fuel efficiency. As an innovative plastic processing method, gas-assisted molding technology is gradually changing the production method of plastic products. As a leading company in the plastic products manufacturing industry, Kaihua Moulds follows the development trend of science and technology and focuses on the research, development and production of automotive plastic products. As early as the early days, the company introduced gas-assisted molding technology and innovatively developed a variety of car door panels. This article will deeply explore the application of gas-assisted molding technology in the manufacturing of automotive plastic products and the advantages it brings.

2. Overview and application of air amplitude technology

Gas-assisted molding ( GAIM) technology is an advanced plastic processing method that injects inert high-pressure nitrogen when the plastic is filled into the mold cavity to push the molten plastic to continue filling the mold cavity and form a cavity in the center of the product. Gas pressure holding replaces the plastic pressure holding process. This technology has significant advantages in improving product quality and reducing production costs.

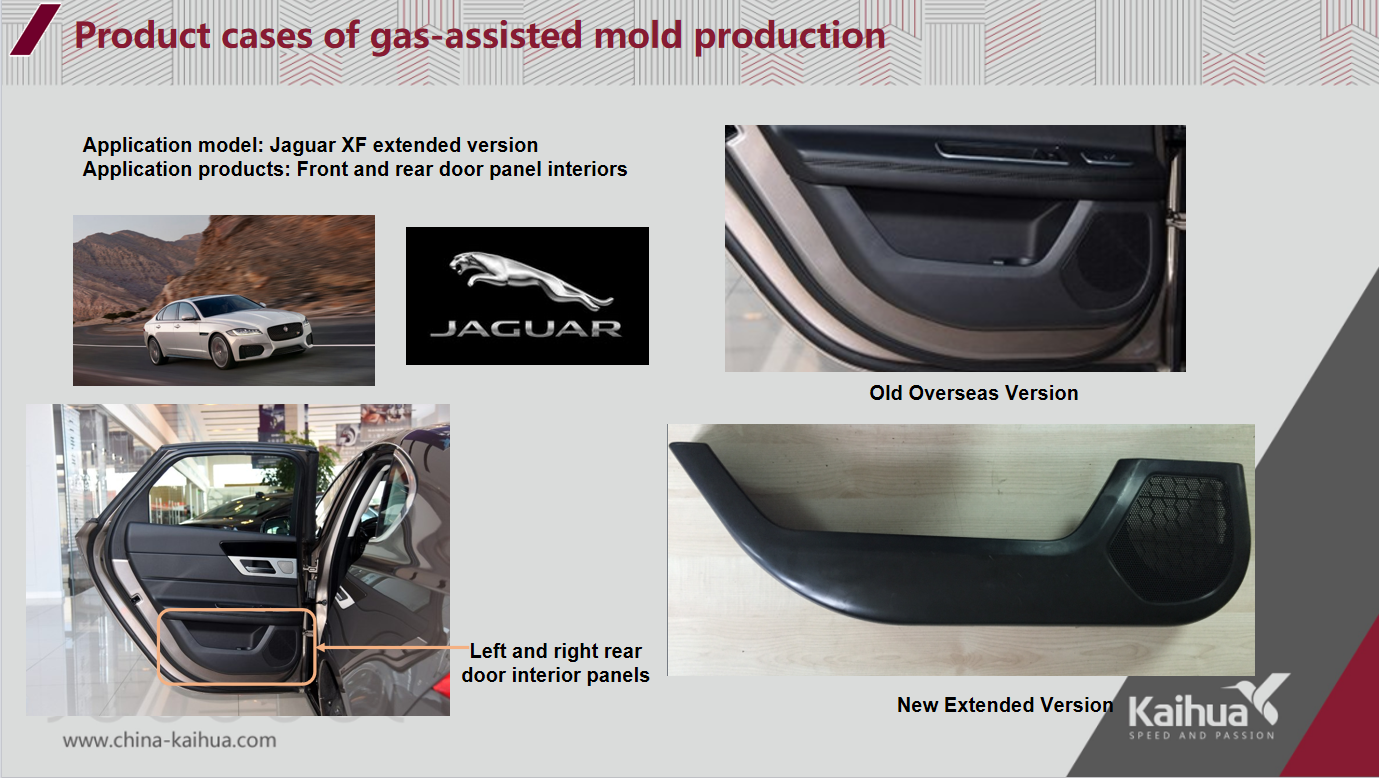

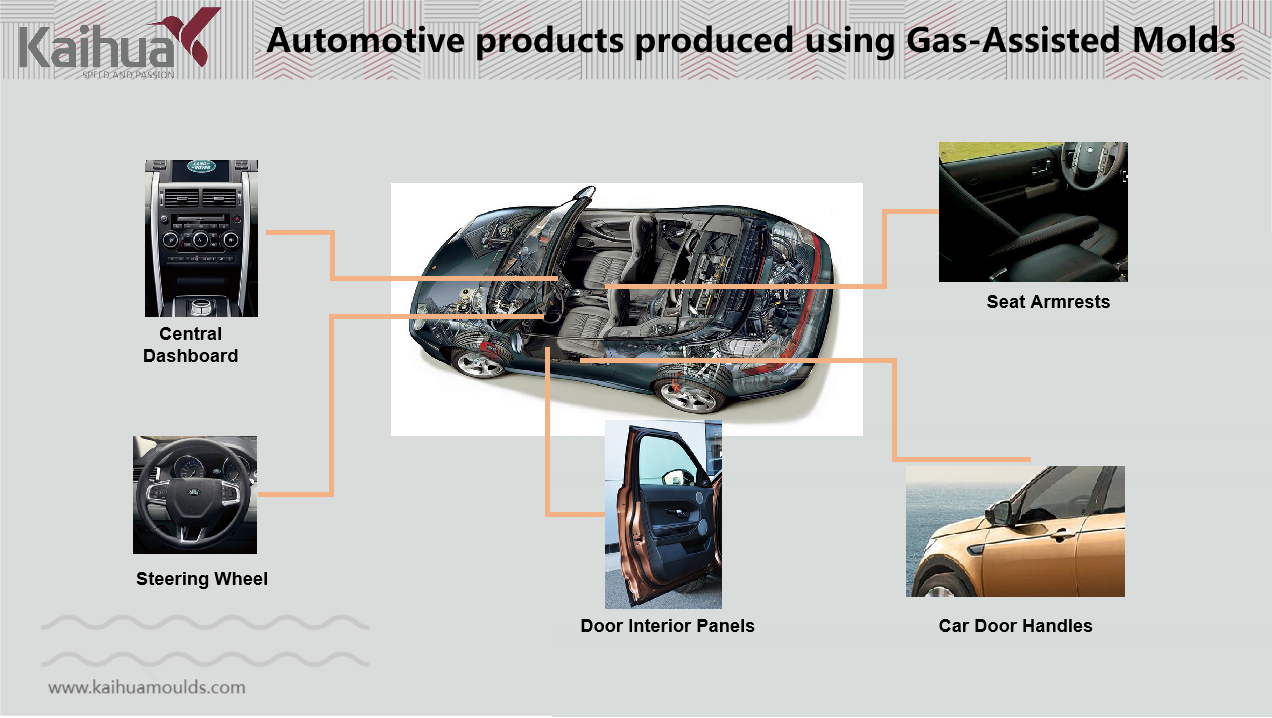

Kaihua Moulds helps customers use gas-assisted molds to produce automotive products: central instrument panels, seat armrests, steering wheels, door interior panels, and car door handles. For example, the Jaguar XF extended version of the front and rear door panel interiors manufactured by Kaihua Moulds.

3. Gas-assisted injection molds have the following advantages:

A. Improve the dimensional uniformity of parts

The parts processed by gas-assisted molding technology have a hollow structure, which will not only not reduce the mechanical properties of the parts, but will actually improve them. At the same time, the dimensional stability of the parts has also been greatly improved.

B. Reduce the working pressure of the injection machine and increase the service life

Gas-assisted molding technology reduces the working pressure of the injection machine injection system and mold clamping system, making the mold suitable for smaller machines, reducing power consumption, and increasing the service life of the injection molding machine and mold.

C. Reduce energy consumption and improve production efficiency

By introducing high-pressure gas, gas-assisted molding technology significantly reduces the shrinkage and deformation of parts, thereby reducing injection holding time and pressure, and reducing energy consumption.

4. Principle of gas-assisted injection molding

First, resin is injected into the mold cavity, and then high-pressure compressed nitrogen is introduced into the molten material. Gas flows in the direction of least resistance toward the low-pressure and high-temperature areas of the product. As the gas flows through the article, it hollows out thick-walled sections by displacing molten material, which fills the remainder of the article. After the filling process is completed, the gas continues to provide holding pressure to minimize shrinkage or warpage of the injection product. Kaihua Moulds deeply understands and applies the principles of gas-assisted injection molding technology.

5. Future development prospects and summary of gas-assisted molding technology

With the continuous development of gas-assisted molding technology and the expansion of application fields, its potential in the automotive industry and other fields is gradually emerging. Kaihua Moulds relies on gas-assisted molding technology to continuously promote innovation in the field of plastic product manufacturing. With the continuous development of technology and the expansion of application fields, this technology is gradually becoming an important force in the automotive plastic products manufacturing industry.

Auxiliary molding is of great significance in improving product quality, reducing production costs, and saving resources. Kaihua Moulds relies on its professional technical team and advanced production equipment to provide customers with high-quality gas-assisted molding technology solutions to help customers achieve dual improvements in production efficiency and product quality. At the same time, Kaihua Moulds is also committed to continuously developing new gas-assisted molding technology to meet the changing market and customer needs.

Post time: Feb-02-2024