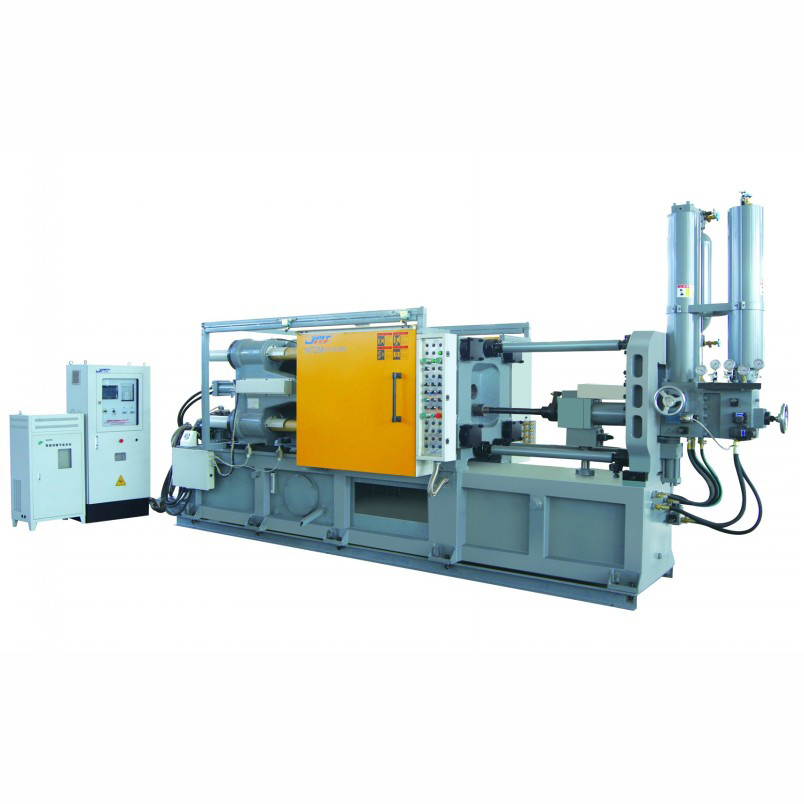

Hot Chamber Die-Casting Machine

1. Product Introduction

Kaihua, a leading provider of innovative die-casting solutions, offers Hot Chamber Die-Casting Machines that are designed to improve productivity and enhance the quality of your products. With our state-of-the-art machinery, you can achieve multi-point settings that extend machine life and reduce burrs, making your manufacturing process more efficient and cost-effective.

We understand the importance of precision across every aspect of your production line, which is why our Hot Chamber Die-Casting Machines come equipped with electric mold adjustments. This feature allows you to effortlessly fit your molds and achieve the highest levels of accuracy in your die-casting process. Our machines are designed to cater to all your needs, simplifying even the most complex tasks.

The Hot Chamber Die-Casting Machines that we offer are ideal for automatic production. Being able to automate production allows you to streamline the manufacturing process, saving you both time and money. Additionally, the machine's intelligent software controls allow you to monitor and fine-tune the process, ensuring your final product meets all required specifications.

At Kaihua, we believe in matching our customers' needs to the best possible products we can offer. Hence, we ensure that our Hot Chamber Die-Casting Machines are designed to meet your specific requirements. Our team of experts works with you to tailor the machines to meet your production needs, resulting in optimal petformance levels.

In conclusion, Kaihua's Hot Chamber Die-Casting Machines represent the perfect balance of quality, precision, and innovation. Our machines assist you throughout the entire die-casting process, from setting up the molds to monitoring production, ensuring exceptional results every time. Contact us to learn more about how our solutions can transform your manufacturing process.

2.Advantages

· Superior injection system has powerful structure and strong design to ensure the good stability.

·High stable toggle system

· Standard with electrical melting furnace,available to supply the fuel furnace,nature gas furnace as special requirement.

· Separate integration of the electrical and electronic systems effectively enhances the stability of the electrical circuit.

· High precision, and functions such as production management, trouble diagnosis

· High performance vane pump,low noise,optimized oil control,improve production efficiency.

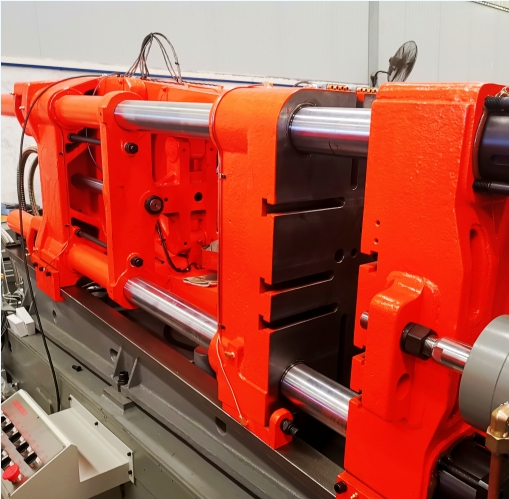

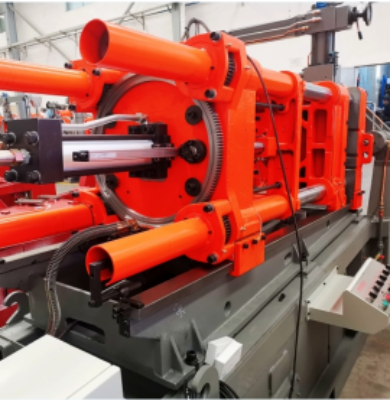

3.Project Cases:

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.