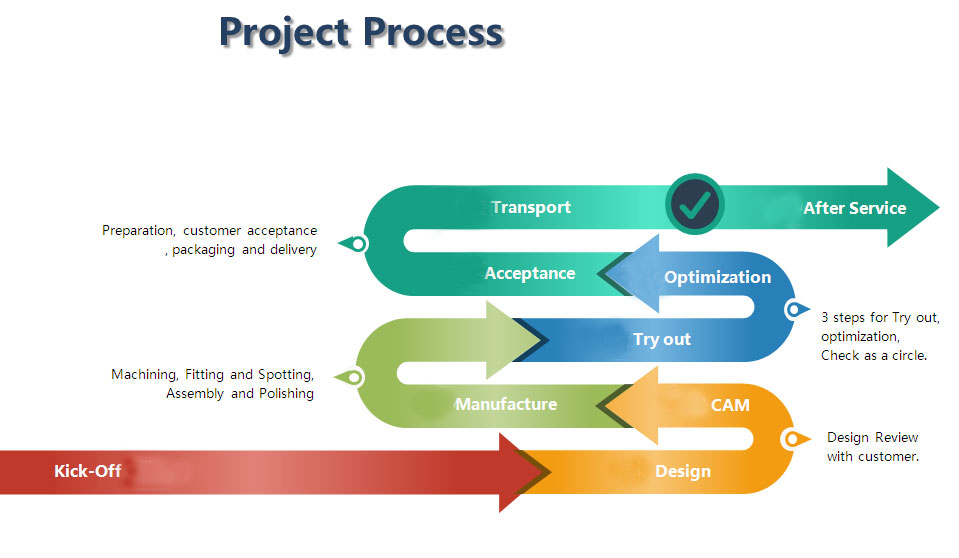

Renewable Design for Wicker Trash Can - 110L Dustbin – KAIHUA

Renewable Design for Wicker Trash Can - 110L Dustbin – KAIHUA Detail:

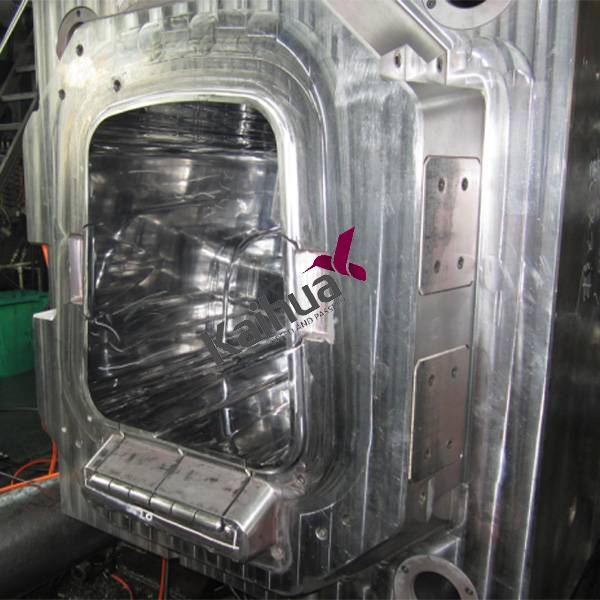

110L Dustbin

Part size : 552*480*899 mm

Mold size :1050*1100*1479mm

Mold weight : 13315kg

Production machine : 2400T

Solution and mould making for dustbin, pallet, crate etc. Most of the moulds are exported to clients in Europe and America market. Currently we can supply large mould weighting up to 90T.

We are capable to make dustbin moulds range from 40L to 3200L. With rich experience we have obtained year by year, our moulds can have very fast cycle time and long mould life. We can provide moulding solutions for industrial crates as well as big agricultural crates. By deep study on how to change versions easily, we help our client to save mould and production cost. No matter small, easy handle pallet or clean, stable pallet for food, hygiene segment. Our moulds are always built with short cycle time as well as easily changeability. Meanwhile, we can provide service for dynamic and static loading analysis.

Logistics division has an average annual capacity of about 200 moulds, the maximum mold can reach 80T. We are good at providing the best solutions for testing standards( such as loading capacity), multi-version interchange and short molding cycle.

Technology Cases

1.Mucell:

The annual average is about 20 sets of cars, household appliances micro-foaming molds. Have the sbility to propose solutions to part design and mold design, and can complete the mold testing on 470t-3300t micro-foaming plastic injection machine.

Advantages: shorten molding cycle, improve dimensional accuracy, eliminate shrinkage of product surface, reduce clamping force and reduce product weight.

Representative customers: Benz, Volkswagen, Great Wall, ford, GEELY.

2.Stack mold technology:

The average annual is about 5-10 sets of stack molds for automobile and household products.

Advantage: reduce mold cost and production cost.

Representative customers: Audi, Ikea.

3.Gas-Assisted Injection Molding:

The annual average is about 20 sets of automobile, household necessities gas-assisted injection molds.

Advantage: reduce production cost, improve product appearance.

Representative customers: Jaguar Land Rover, RESOL.

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Renewable Design for Wicker Trash Can - 110L Dustbin – KAIHUA , The product will supply to all over the world, such as: Benin, Azerbaijan, UK, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!