Standard Logistics Turnover Box Mold Logistics Packaging

1.Product Introduction

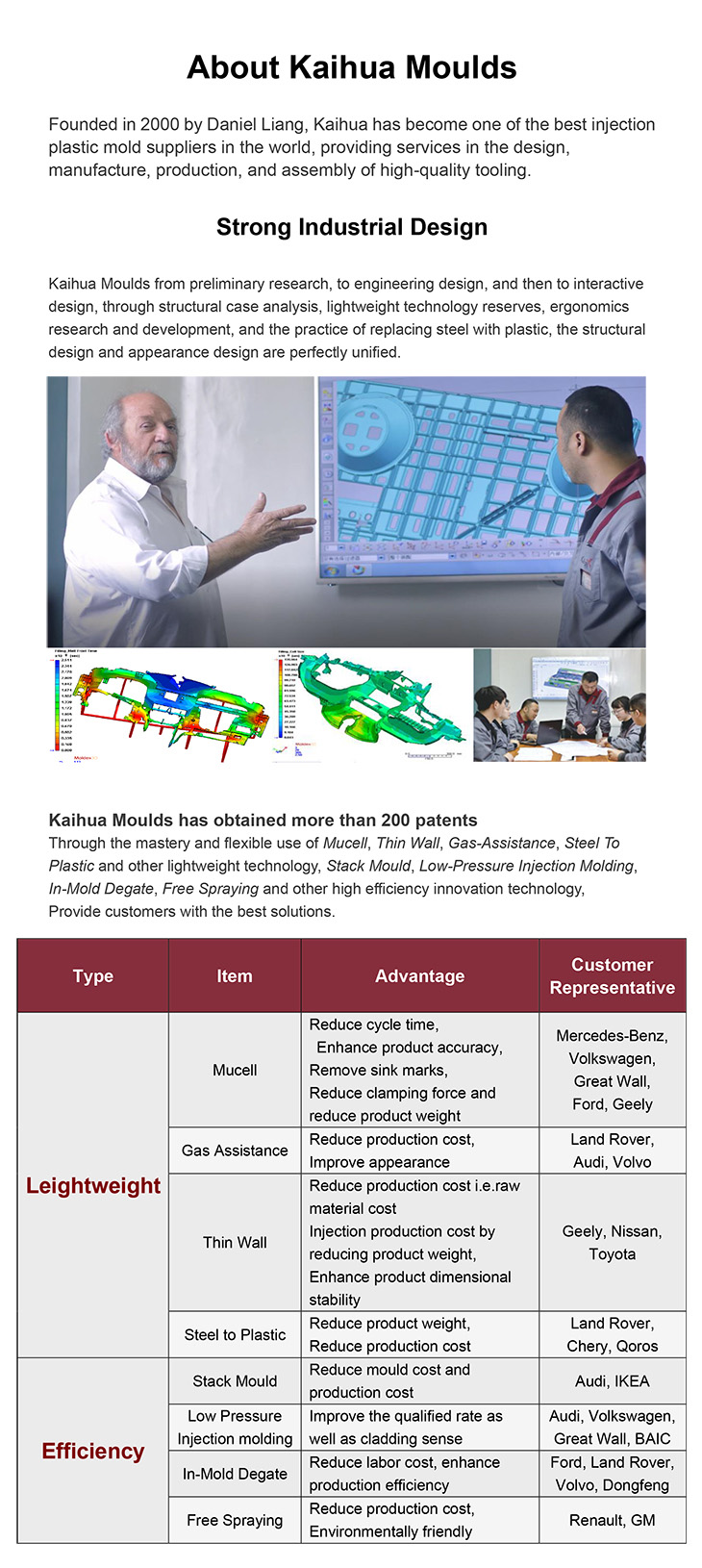

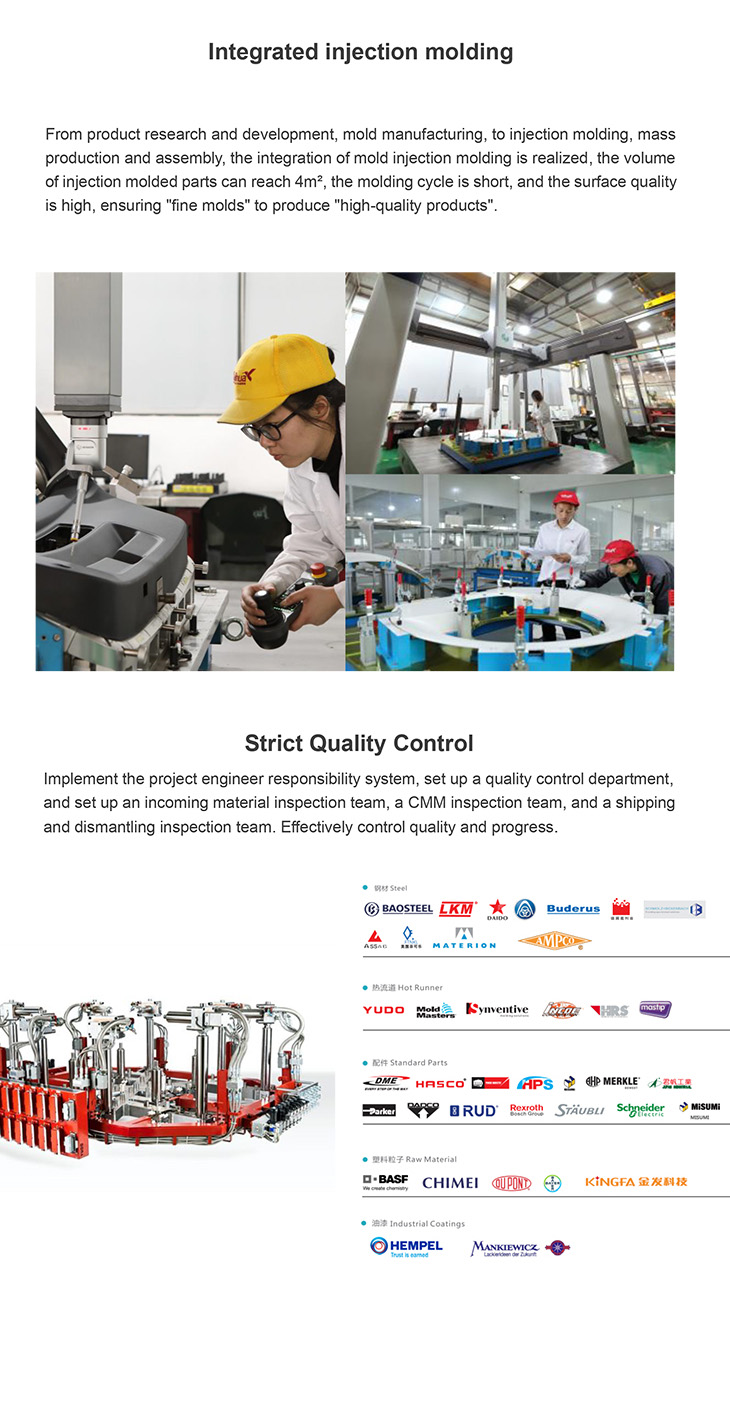

As a national high-tech and manufacturing champion enterprise, Kaihua Moulds brings 25 years of expertise to high-quality custom injection molds for global clients—with the Standard Logistics Turnover Box Mold as a flagship solution tailored for international logistics, agriculture and warehousing.

Designed for customization and premium performance, the Kaihua Moulds Standard Logistics Turnover Box Mold features a flexible modular structure, optimized via CAE mold flow simulation for ideal waterway and hot runner layouts, adapting seamlessly to heavy-load or lightweight design needs. Every detail is engineered for molding efficiency and end-product usability.

Kaihua Moulds equips the Standard Logistics Turnover Box Mold with premium steels (Buderus, ASSAB, Baosteel) treated with nitriding, plus DME/HASCO standard parts for easy maintenance. Partnering with top hot runner brands (Synventive, Mold-Masters, etc.), we ensure stable injection performance for this specialized mold.

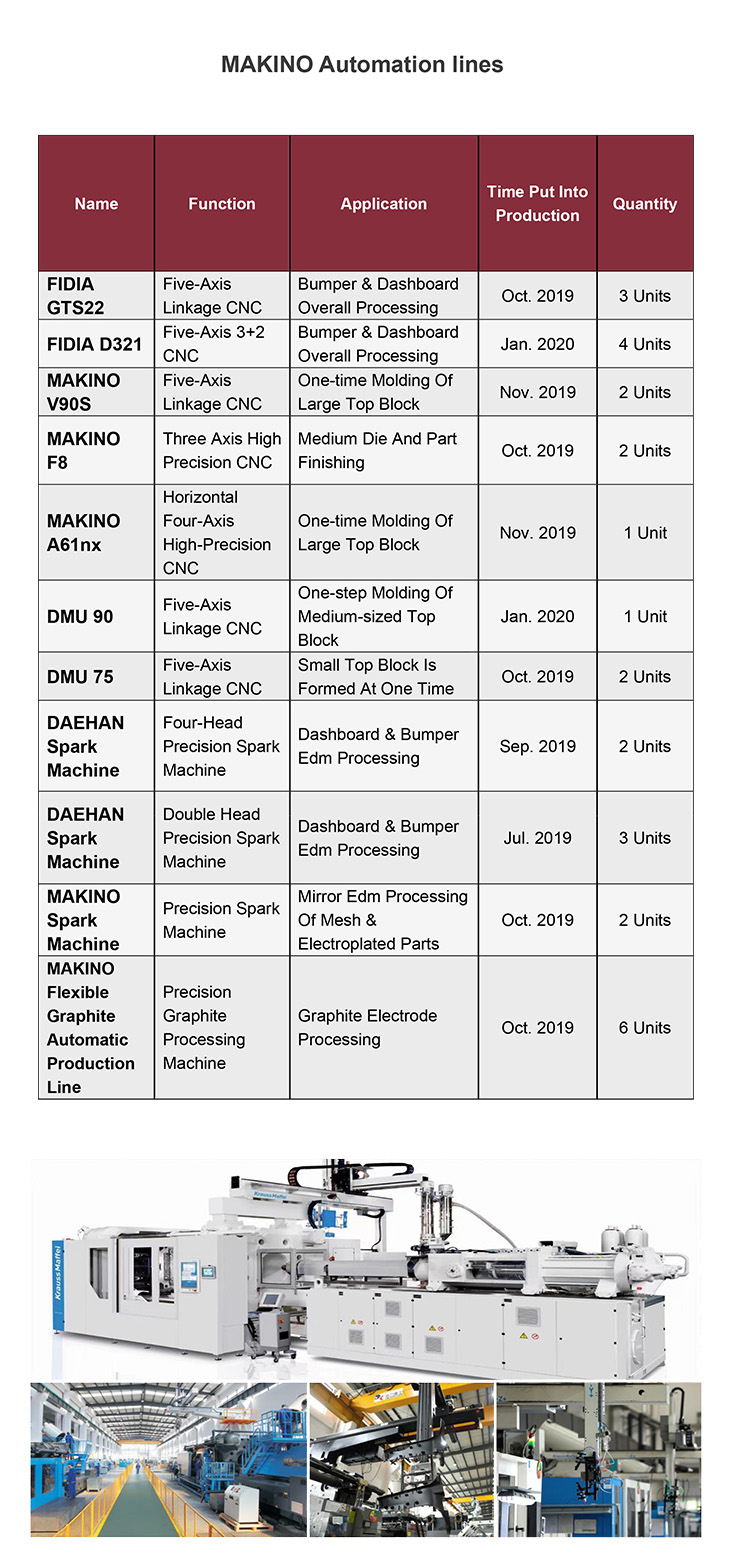

The Kaihua Moulds Standard Logistics Turnover Box Mold leverages core technologies like MuCell®,In-mold Degate, paired with world-class equipment (MAKINO, DMG, HEXAGON), and complies with ISO 9001, ISO 14001 standards—upholding our quality commitment.

With 15 overseas branches, Kaihua Moulds delivers global customization and after-sales support for the Standard Logistics Turnover Box Mold, providing tailored solutions that align with your global business needs.

Explore more of Kaihua Moulds' precision solutions — from Plastic Pallet Injection mould and Foldable Crate Mold to Waste Bin Injection Mould.

2.Product Display

| Part Name | Base |

| Mold weight(t) | 23.4 |

| Product weight(g) | 17600 |

| grain or electroplate | Polishing |

| Demolding requirement | Gripper |

| Product materials | HDPE |

| Injection Machine(t) | KM2700 |

| Part Name | Base |

| Mold weight(t) | 11.5 |

| grain or electroplate | Polishing |

| Demolding requirement | Gripper |

| Product materials | HDPE |

| Injection Machine(t) | 1100/1500T |

3.Product Display

Base

Base

Side

Side

Side

4.Product feature and application

5.Kaihua Service

(1) Product feature

Kaihua Moulds Standard Logistics Turnover Box Mold, a premium Plastic Injection Mold and Crate Mold, boosts global Logistics Packaging efficiency with precision and durability. This Plastic Crate Mold produces robust Plastic Turnover Box and Injection Storage Box solutions, featuring strong stacking stability and resistance to handling, extreme temperatures, and oils, with food-grade materials available for hygiene needs. Its modular design supports customization, while seamless compatibility with automated systems ensures consistent output—delivering reliable Plastic Turnover Box Mold performance tailored to global logistics demands.

(2) Product application

Kaihua Moulds' Standard Logistics Turnover Box Mold is a fully customizable solution engineered to meet diverse Logistics Packaging requirements across industries.

For e-commerce and retail, this Plastic Turnover Box Mold maximizes storage density and handling efficiency, ideal for high-volume, fast-moving consumer goods during peak seasons.

For automotive and machinery sectors, the Plastic Crate Mold delivers reinforced and impact-resistant Plastic Turnover Box solutions for parts, components, and tools.

For agriculture and fresh produce logistics, the mold enables ventilated, lightweight Plastic Crate designs that ensure freshness, durability, and easy stacking during long-distance transport and cold-chain distribution.

When configured with food-grade materials, the Crate Mold provides hygienic, easy-to-clean Injection Storage Box options ideal for food processing and pharmaceutical logistics.

Meanwhile, for electronics and light industry, the Plastic Injection Mold supports customized anti-static and scratch-resistant designs that safeguard delicate products in transit.

From manufacturing to distribution, the Standard Logistics Turnover Box Mold delivers durable, tailor-made packaging solutions that enhance efficiency, safety, and reliability across the global supply chain.

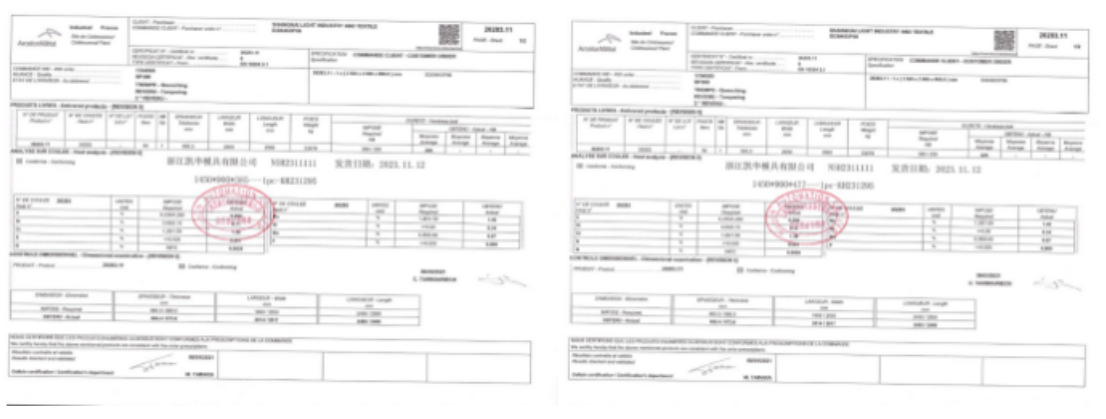

6.Product qualification

(1)Car Lamp Injection Mould Trial Process

Kaihua conducts a rigorous trial molding process for every Auto Lamp Injection Mould to ensure optimal performance before mass production. During the trial, we test mold flow, injection parameters, and cooling efficiency to verify stability and repeatability under high-volume conditions. Each sample part is inspected for dimensional accuracy, surface finish, and structural strength, confirming that the handle components meet durability, functional, and aesthetic requirements. This process guarantees that the mould can deliver consistent quality across different vehicle models while supporting the efficiency of large-scale automotive interior production.

(2)Product shipment and packaging photos

(3)Design review photos

(4)Photos of the Technical Department Meeting

(5)Certificate

To learn more about Kaihua's certificates, please click here