Up to 1100L-120L Waste Bin Injection Mould

1.Product Introduction

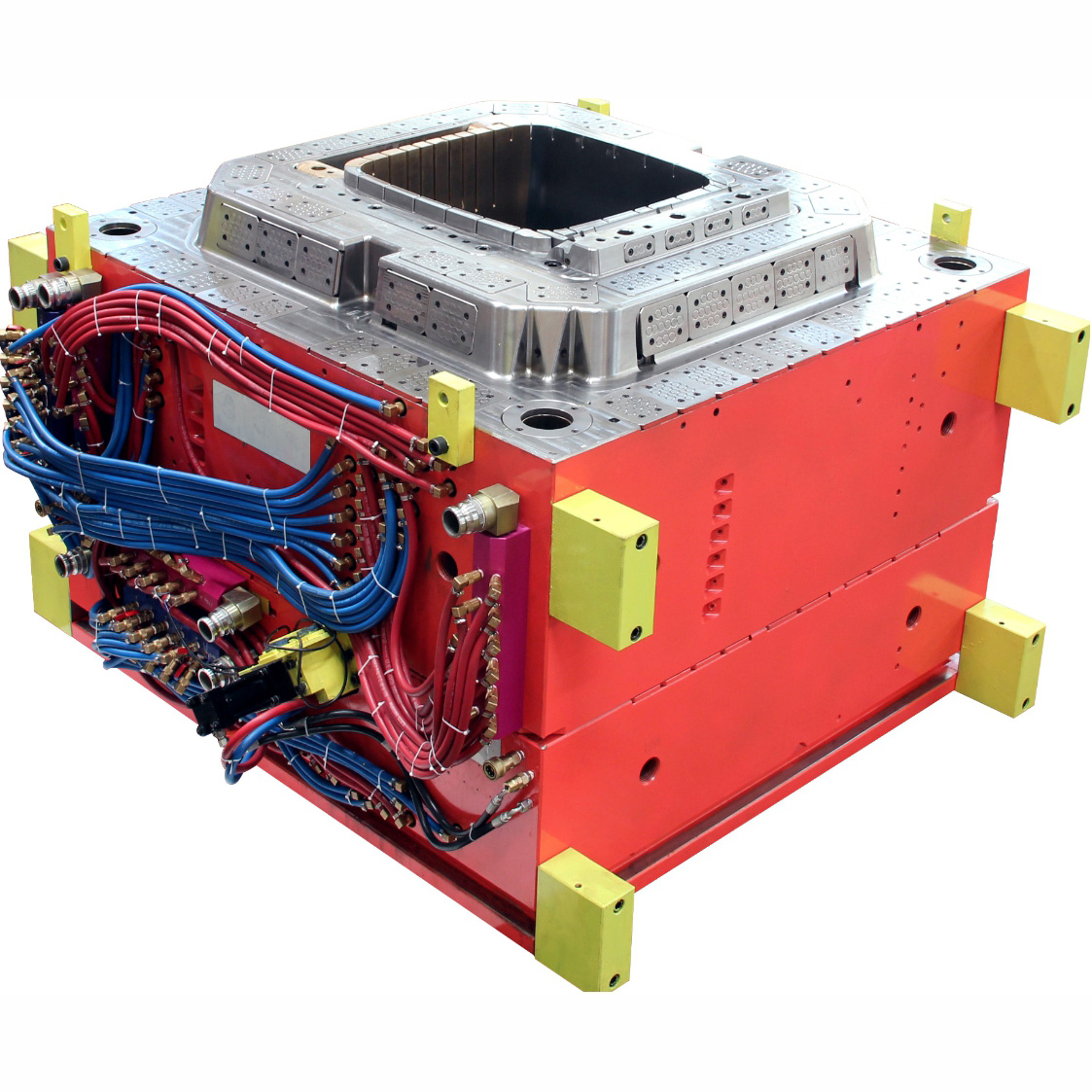

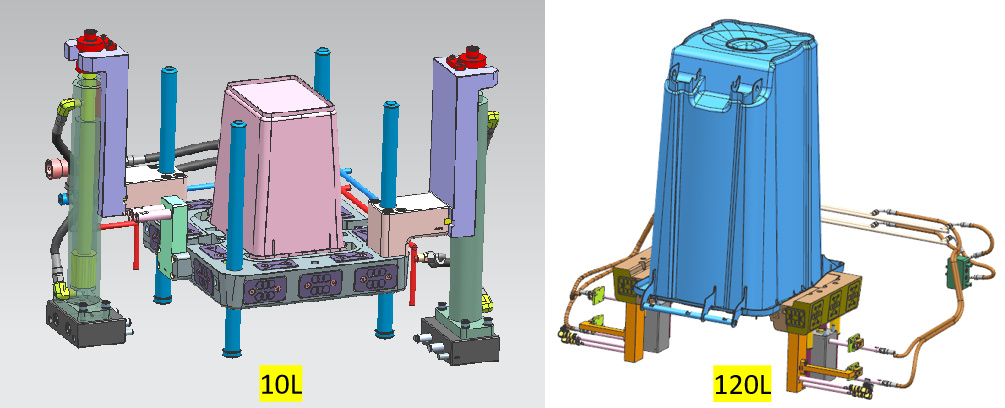

Kaihua Mold is proud to offer top-of-the-line moulding solutions for Waste Bin Injection Moulds ranging in sizes from 10L-42L, all the way up to a whopping 1100L. We understand the importance of efficient production and cost savings, and that's why we've made it our mission to provide exceptional moulds that are easily adaptable to different versions in order to reduce mould and production costs for our clients.

Our range of Waste Bin Injection Moulds includes models for Rubbish Bins, Wheelie Bins, Trash Cans, and Litter Bins, all designed with fast cycle times and long mould lives. We've invested significant time and resources into research and development to ensure that our moulds consistently meet and exceed industry standards.

At Kaihua Mold, we pride ourselves on our technical expertise and high-quality craftsmanship. Our team of dedicated professionals work tirelessly to ensure that each and every mould is built to the highest standard, with precision and attention to detail being our top priority. We use only the highest-quality materials and equipment, and our state-of-the-art facilities are equipped with the latest technology to ensure that our moulds are always of the highest possible quality.

Whether you're looking for a small-scale Waste Bin Injection Mould or a large-scale 1100L model, we have the knowledge, expertise, and experience to deliver the best possible moulding solutions. We work closely with our clients to fully understand their unique needs and requirements, enabling us to design and build moulds that are tailored specifically to their needs.

At Kaihua Mold, we're committed to providing the best possible customer experience, with exceptional service and support every step of the way. Whether you're looking for support with product design, manufacturing, or after-sales service, our team of experts is always on hand to help.

In summary, if you're in the market for a top-quality Waste Bin Injection Mould, look no further than Kaihua Mold. Our extensive range of moulds, technical expertise, and commitment to excellence make us the ideal partner for your moulding needs.

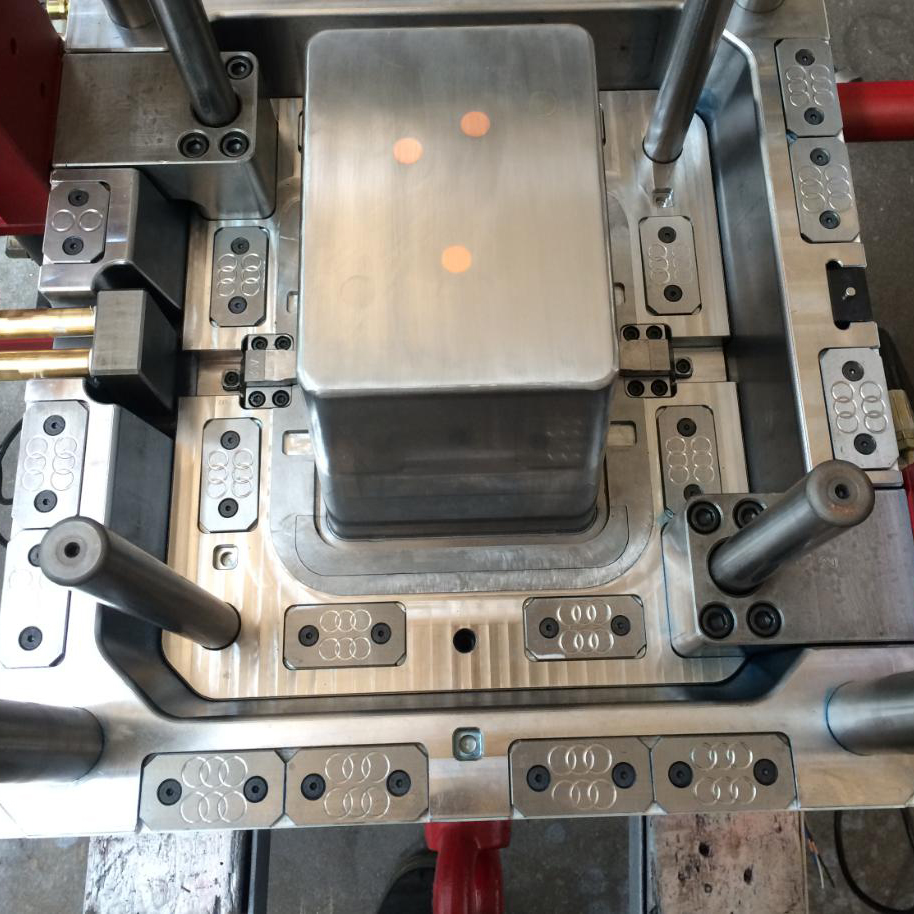

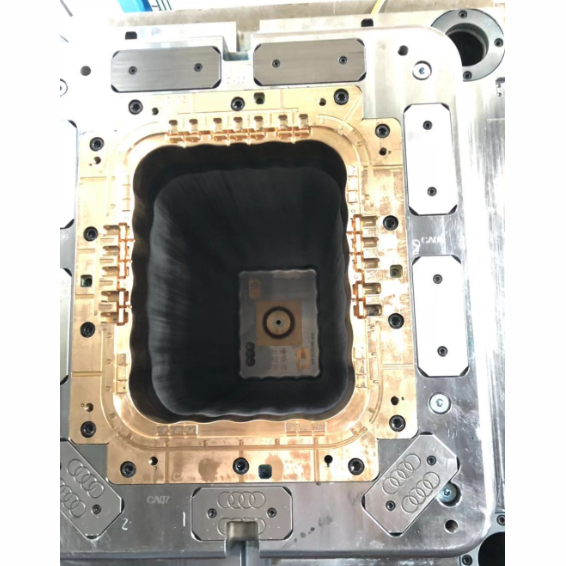

2.Product Parameter (Specification)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME or your requirement |

| Mold Material | 45#, P20, H13, 718, 1.2344, 1.2738 or your requirement |

| Standard | HASCO, DME, MISUMI, PUNCH, or your requirement |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or your requirement |

| Runner | Cold/Hot Runner |

| Gate TypeProducts Size | Side gate, Sub gate, Pin point gate, Edge gate etc10L-42L, up to 1100L. or your requirement |

3.Product Feature and Application

4.Production Details

We are able to check Injection mold design and run professional simulations to make sure that the product design can match with different standard.

For example, EN 840 norms for mobile waste containers.

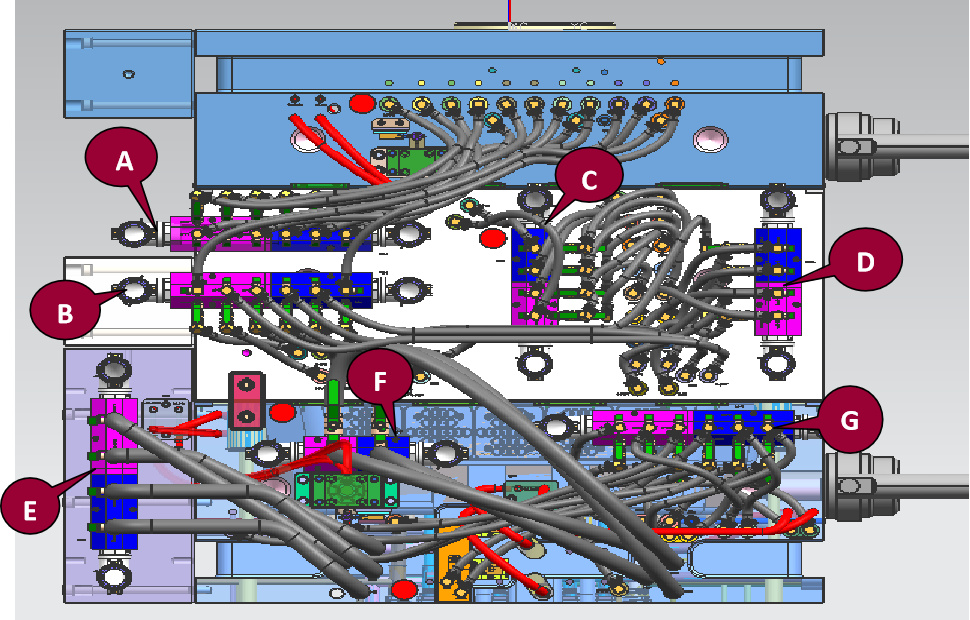

5.Cooling

Example: 240L waste bin

Cycle time: ≦60s including robot pickup

There are 7pcs independent cooling manifolds with large size inlet/outlet connectors, which we can use them to control the temperature of each zones.

cavity side: A, B, C and Dcore side: E, F and G

Multiple cooling manifolds with

valve will ensure water flow controls.

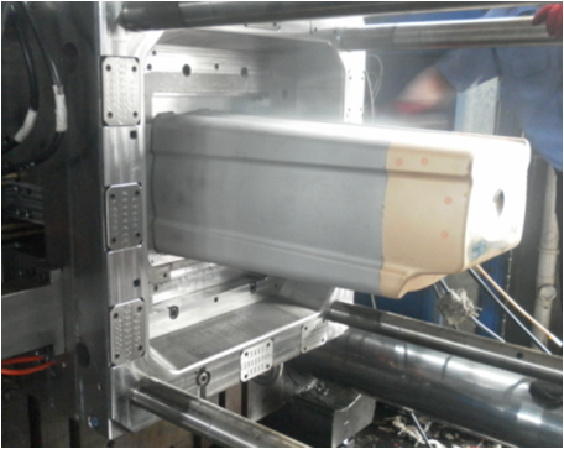

6.Ejection

We will design good and reliable ejection system.

Sometimes it will be ejector blocks, or it can be stripper plate too.

Sometimes we use only air valves and robot to take out parts.

The ejection must be as simple as possible and design for easy maintenance.

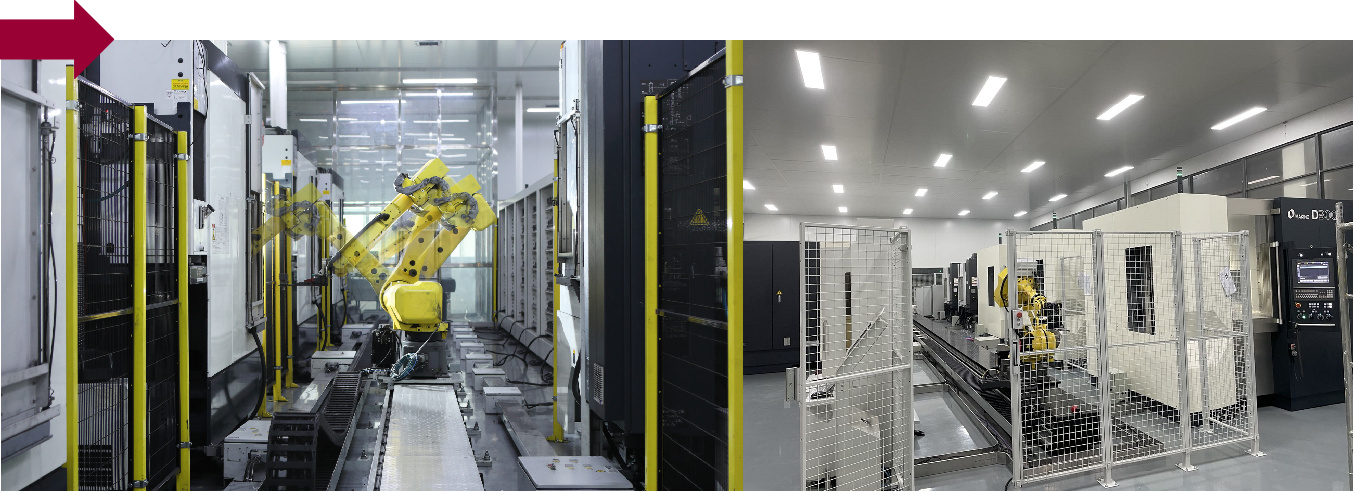

7.Machinery

Small to large size CNC including 5 axis high speed CNC

MAKINO Automation lines

Spotting machine 100-500T,

capable for all kind of injection moulds

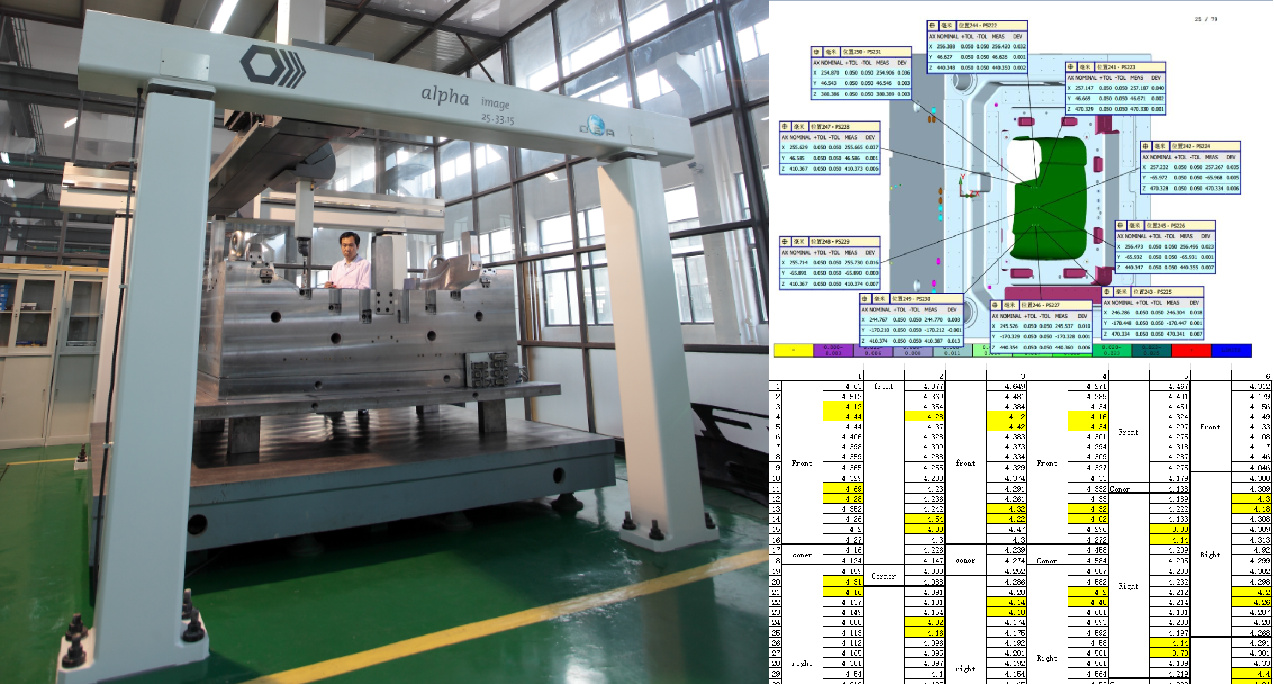

CMM – dimensions/thickness

Krauss Maffei machines, all with robots,

from 160-1600T(multi-injection)

3200T injection machine, parallel movements, hydraulic clamping, with 6-axix ABB robot.

It is not the biggest machine that we have. We are now buying up to 5500T injection machine.

8.Advantages

√ Increase efficiency and reduce energy consumption.

√ Full-closed design and sound-proofing ensure low noise level..

√ The blade material is imported steel to ensure high quality and high durability.

√ Equipped with electrical current relay, motor overload protector and other multiple safety devices.√ Convenient motor replacement.

√ Dust separator, full-receiver alarm device and special screens.

● High Quality (Product &Mould)

● On-time Delivery (Sample, Mould)

● Cost Control (Direct Cost, Indirect Cost)

● Best Service (Customers, Employee, Other Department, Supplier)

● Form— ISO9001:2008 Quality management systems

● Process—Project Management

● ERP management system

● Standardization—Performance Management