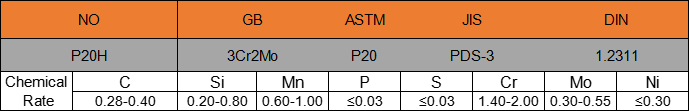

Steel P20H

1. Product Introduction

As an international general-purpose plastic mold steel, P20H has become increasingly popular among mold manufacturers. It can be used in various types of molds, including thermoplastic molds, extrusion molds, blow molds, vacuum degassing and ESR remelting. Its excellent mirror polishing performance and low sulfur and gas content make it a perfect choice for large and medium-sized and precision mold forming parts, home appliance appearance molds, and other high-quality plastic mold applications.

Kaihua Mold has been dedicated to producing high-precision plastic molds for more than 20 years. Our skilled technicians and advanced equipment have allowed us to produce high-quality molds that meet the needs of a range of industries, including automotive, medical, and electronic components. We understand that producing high-quality molds requires using high-quality materials and that is why we choose to use P20H steel in many of our molds.

The low sulfur and gas content of P20H steel means that it can be easily processed using forging and rolling techniques, and it does not crack or deform during processing. This is essential for producing high-quality molds that meet the exact specifications of our customers. In addition, P20H steel has excellent mirror polishing performance, which means that the surface of our molds is smooth and precise, allowing for high-quality finished products.

At Kaihua Mold, we take pride in our ability to produce high-quality molds using the best materials available. We believe that using P20H steel has allowed us to produce molds that meet and exceed the expectations of our customers. We are committed to continuing to use the best materials available and to continuing to improve our processes to produce even higher quality molds in the future.

In conclusion, P20H steel is an excellent choice for plastic mold applications, and its use in Kaihua Mold’s products is a testament to its quality and the commitment of our team to producing high-quality molds. We will continue to use the best materials available to ensure that our customers receive the highest quality products possible.

2. Advantages

· High Quality

· Short Cycle

· Competitive Cost

3. Classification

4.Kaihua Mould Advantage :

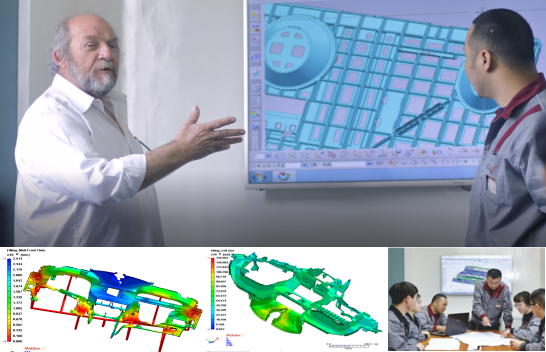

Strong Industrial Design

Kaihua Car Lamp Moulds from preliminary research, to engineering design, and then to interactive design, through structural case analysis, lightweight technology reserves, ergonomics research and development, and the practice of replacing steel with plastic, the structural design and appearance design are perfectly unified.

Kaihua has obtained more than 200 patents.

Through the mastery and flexible use of Mucell, Thin Wall, Gas-Assistance, Steel To Plastic and other lightweight technology, Stack Mould, Low-Pressure Injection Molding, In-Mold Degate , Free Spraying and other high efficiency innovation technology,

Provide customers with the best solutions.

|

Type |

Item |

Advantage |

Customer |

|

Leightweight |

Mucell |

Reduce cycle time,Enhance product accuracy,

Remove sink marks, Reduce clamping force and reduce product weight |

Mercedes-Benz, Volkswagen, |

|

Gas Assistance |

Reduce production cost, Improve appearance |

Land Rover, |

|

|

Thin Wall |

Reduce production cost i.e.raw material cost/Injection production cost by reducing product weight, Enhance product dimensional stability |

Geely, Nissan, Toyota |

|

|

Steel to Plastic |

Reduce product weight, Reduce production cost |

Land Rover, |

|

|

Efficiency |

Stack Mould |

Reduce mould cost and production cost |

Audi, IKEA |

|

Low Pressure |

Improve the qualified rate as well as cladding sense |

Audi, Volkswagen, |

|

|

In-Mold Degate |

Reduce labor cost,enhance production efficiency |

Ford, Land Rover, |

|

|

Free Spraying |

Reduce production cost, Environmentally friendly |

Renault, GM |

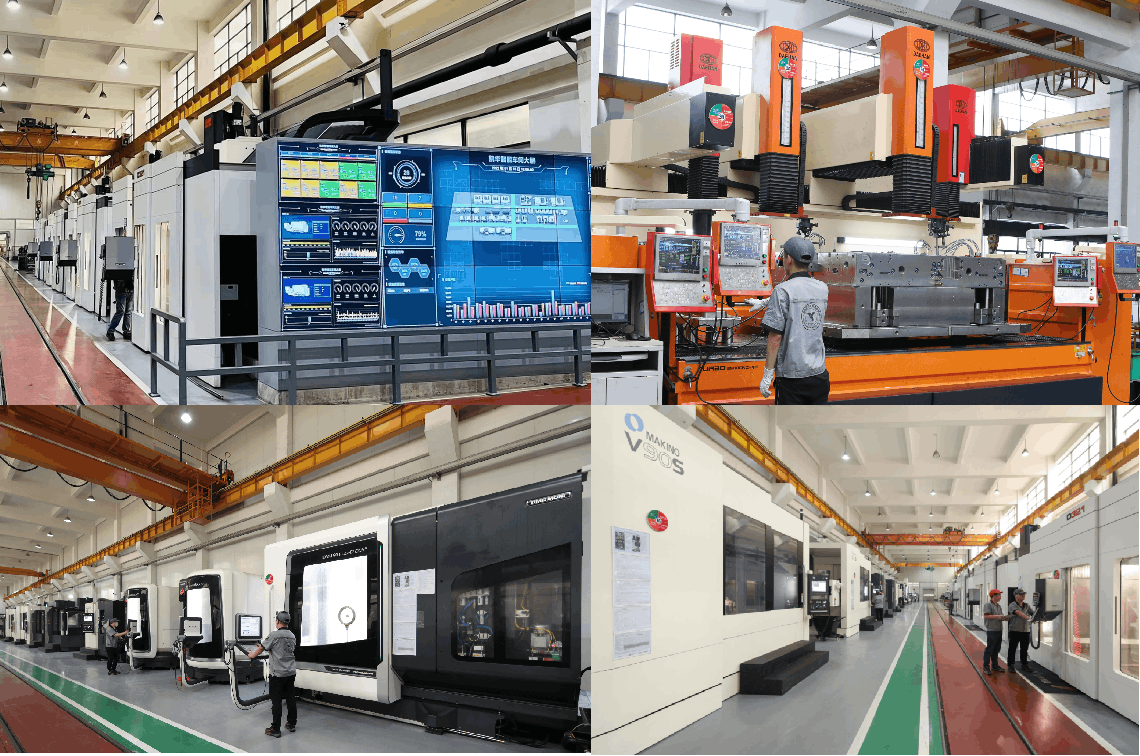

Machinery

Injection Production Equipment

■ Krauss Maffei 1600T Three-color Injection Molding Machine

1) Three-color injection molding, Core Back function, DIY main nozzle translation and other functions

2) It can be applied to two-color/three-color injection of headlights, chemical foamed door panels, injection-molded compression spoilers, etc.

■ YIZUMI 3300T Injection Molding Machine with 5 Axis Pickup

■ 17 Injection Molding Machines Covering 160T ~ 4500T

Five-Axis Linkage Mold Processing Equipment

■ FIDIA, Italy

■ MAKINO, Japan

■ DMU, German

■ 12 in Total

■ ……

High Precision Spark Machine

■ DAEHAN

■ MAKINO

■ 7 in Total

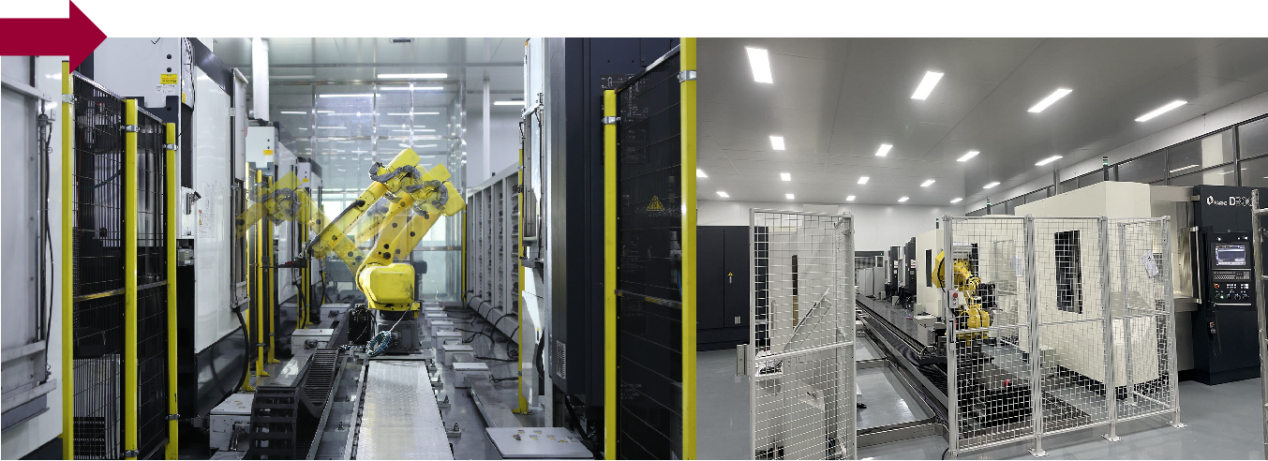

MAKINO Automation lines

|

Name |

Function |

Application |

Time Put Into Production |

Quantity |

| FIDIA GTS22 | Five-Axis Linkage CNC | Bumper & Dashboard Overall Processing | Oct. 2019 | 3 Units |

| FIDIA D321 | Five-Axis 3+2 CNC | Bumper & Dashboard Overall Processing | Jan. 2020 | 4 Units |

| MAKINO V90S | Five-Axis Linkage CNC | One-time Molding Of Large Top Block | Nov. 2019 | 2 Units |

| MAKINO F8 | Three Axis High Precision CNC | Medium Die And Part Finishing | Oct. 2019 | 2 Units |

| MAKINO A61nx | Horizontal Four-Axis High-Precision CNC | One-time Molding Of Large Top Block | Nov. 2019 | 1 Unit |

| DMU 90 | Five-Axis Linkage CNC | One-step Molding Of Medium-sized Top Block | Jan. 2020 | 1 Unit |

| DMU 75 | Five-Axis Linkage CNC | Small Top Block Is Formed At One Time | Oct. 2019 | 2 Units |

| DAEHAN Spark Machine |

Four-Head Precision Spark Machine | Dashboard & Bumper Edm Processing | Sep. 2019 | 2 Units |

| DAEHAN Spark Machine |

Double Head Precision Spark Machine | Dashboard & Bumper Edm Processing | Jul. 2019 | 3 Units |

| MAKINO Spark Machine |

Precision Spark Machine | Mirror Edm Processing Of Mesh & Electroplated Parts | Oct. 2019 | 2 Units |

| MAKINO Flexible Graphite Automatic Production Line | Precision Graphite Processing Machine | Graphite Electrode Processing | Oct. 2019 | 6 Units |

Integrated injection molding

From product research and development, mold manufacturing, to injection molding, mass production and assembly, the integration of mold injection molding is realized; the volume of injection molded parts can reach 4m², The molding cycle is short, and the surface quality is high, ensuring "fine molds" to produce "high-quality products".

Strict Quality Control

Implement the project engineer responsibility system, set up a quality control department, and set up an incoming material inspection team, a CMM inspection team, and a shipping and dismantling inspection team. Effectively control quality and progress.

Top Partner

Frequency Asked Questions

Q: Can you do the finished product or parts Only?

A: Sure, We could do finished product according the customized mold. And make the mold also.

Q: Can I test my idea/product before committing to mould tool manufacture?

A: Sure, we can use CAD drawings to make models and prototyping for design and functional evaluations.

Q: Can you do Assemble?

A: Of cause we could do. Our factory with assembly room.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q: What type of mould tool do I need?

A: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q: I have an idea for a new product, but not sure if it can be manufactured. Can you help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Welcome your inquires and emails.

All inquires and emails will be replied within 24 hours.