As the smallest container unit, pallets can be used with forklifts, stackers and other equipment in logistics handling, and their applications are becoming more and more widespread.

Plastic pallets are favored by various industries such as food, pharmaceutical, chemical and cold chain for their own non-toxic and tasteless, acid and alkali resistant, bright and clean appearance, no nails and no thorns, etc. How to choose plastic pallets? What should we pay attention to when choosing plastic pallets?

First of all, we have to choose according to our own use scenario.

Different companies have different application scenarios and the pallets have different scope of application. Therefore, you should know the following before you buy:

1. What size of plastic pallet to use

Due to different industries and different sizes of product packaging, the size of matching pallets also varies greatly. For example, cartons of cigarettes can fit neatly on a 1250 x 1000mm pallet, while the size for the automotive industry is 1200 x 1000mm.

The use of these two pallets covers nearly 50% of the packaging sizes in the market and is the standard size for logistics standardization to achieve a common domestic pallet. Considering the advantages of pallet sharing, it is recommended to choose 1200×1000mm pallet in the case of small difference in packaging size.

2、How much weight-bearing the pallet needs

To clarify how much cargo needs to be put on the pallet, corresponding to the different pallet structure. There are light, medium and heavy pallets. Lightweight pallet weight less than 300kg; medium pallet 300 ~ 800kg; 800kg load above the general need to choose heavy-duty pallet, special requirements need to add steel pipe on the plastic pallet.

3. What kind of plastic pallet to use

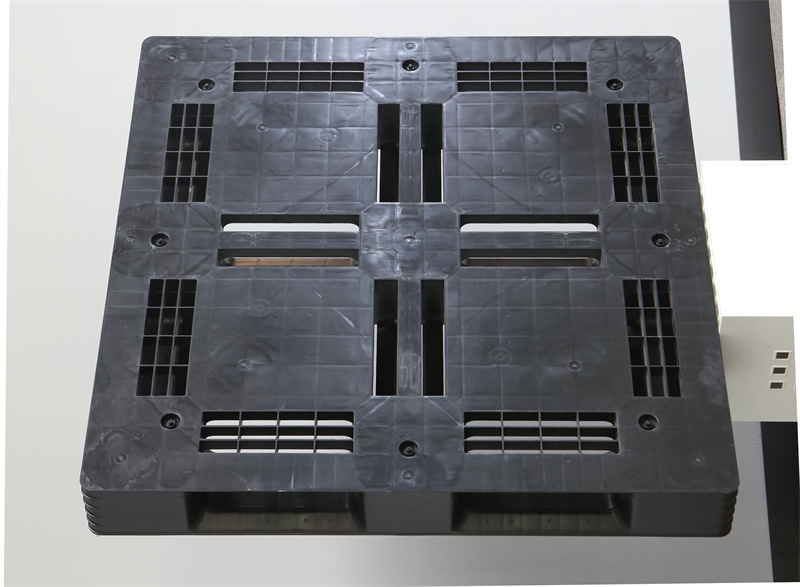

There are two kinds of pallets, Single Face Plastic Pallet and double-deck plastic pallet.

Single face plastic pallets have only one load-bearing surface to place goods, and the other surface is used to support handling equipment. Common single face plastic pallet are grid nine feet, flat nine feet,flat three runners;

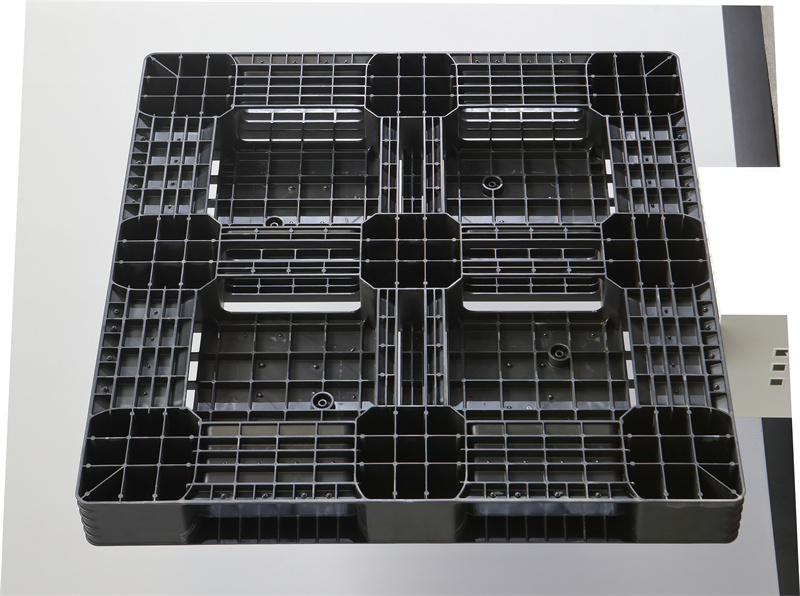

Double-deck plastic pallet is the goods of two load-bearing surface can be placed, handling tools into the load-bearing surface between the forks.

Double-deck plastic pallet multi-layer stacking stability, single-sided pallets multi-layer stacking relatively unstable.

4、What structure of plastic pallet is needed

The common plastic pallet structure is grid-shaped, with the advantages of ventilation, no wind leakage, dust and dust leakage, light and non-slip.Currently widely used in all walks of life;

Another pallet is flat plastic pallets, the advantage of which is easy to clean, widely used in food, medicine and other industries with high health requirements.

5、Understand what is the supporting plastic pallet handling tools

It is also necessary to understand what handling equipment is available in the warehouse. If it is a new project that has not yet purchased transportation equipment, you need to choose the right transportation equipment according to the shipping volume, shipping speed, single pallet load weight and other factors.

Common handling equipment is a manual hydraulic truck to support the pallet structure can only be a single-sided use of plastic pallets.

In the case of forklift, you can consider using double-sided plastic pallets.

6、Understand the special use requirements of the plastic pallet use sector

After understanding the above points, you can basically choose a suitable plastic pallet, and then use the pallet by the use department. Therefore, before choosing the pallet, it is better to ask the use department to put forward requirements, especially special requirements, such as temperature requirements, whether there are anti-static requirements, etc.

Second, pay attention to the plastic pallet material

As the saying goes, the price is the same as the price.The quality of the product has a lot to do with the material.Pallets made of high-quality materials is too hard and resistant to falling and crashing.Products made of inferior materials are more problematic and easy to break.

First, it should be noted that most manufacturers on the market use plastic that has been recycled many times to process plastic pallets. Since the materials are used many times in the furnace, the physical properties of the materials are greatly reduced. The rate of pallet damage in long-term use is extremely high (the difference in performance in the short term is not significant).

Again, choose the right product by sample comparison or trial.

The advantages and disadvantages of plastic pallets cannot be seen from the pictures. If a size model is determined, then consider having the supplier provide samples for on-site comparison. By comparing in kind, it will be immediately obvious. Of course, the sample fee needs to be considered when purchasing.

In summary, these are the considerations for buying plastic pallets.

Kaihua founded in 2000.In the context of extending its business scope, Kaihua has invested 320 million RMB establishing Kaihua Logistics & Environmental Technology, as a subsidiary to focus on the development of logistics plastic injection moulds and products. With a total over 75000 square meters, Kaihua Logistics & Environmental Technology manufacturing plant will be able to provide premium products and services through its strong industrial design abilities, advanced mold flow technologies and high-quality mould manufacturing capabilities.

Currently, Kaihua Logistics & Environmental Technology is cooperating with IPL Group, Tri-wall, OTTO and Nongfu Spring for long terms.

Post time: May-29-2023