Technological Information

-

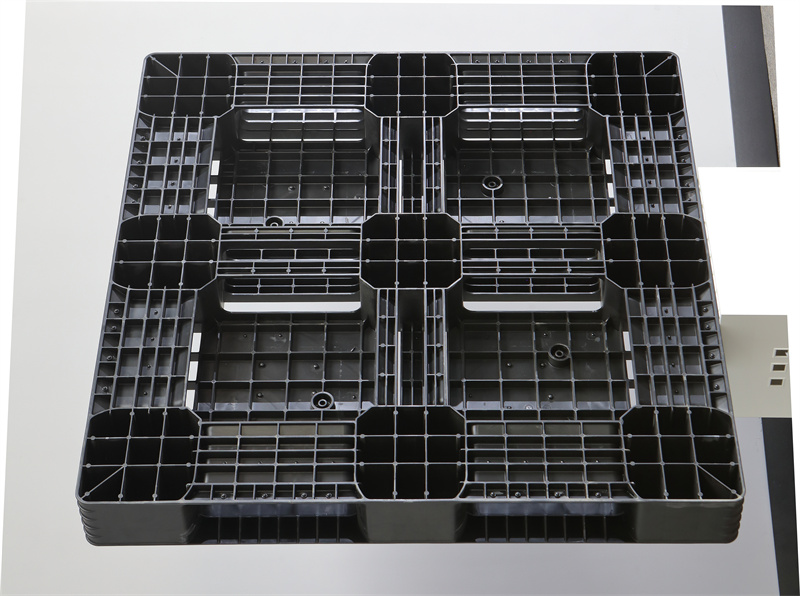

KAIHUA NEWS |Stackable Plastic Pallets: A Logistics Space Revolution Driven by Injection Molding Technology

In the modern logistics system, stackable plastic pallets are quietly driving an efficiency revolution. This seemingly simple logistics carrier embodies the essence of injection molding technology and has become an indispensable infrastructure in the global supply chain. From raw materials to fin...Read more -

Kaihua’s Stack Mould Technology Breaks Production Limits, Leading Smart Manufacturing Revolution in Injection Molding

Amid the wave of intelligent and high-efficiency transformation in the plastic mold industry, Kaihua Mold has successfully applied stack mould technology to both automotive mold manufacturing and household mold production. This breakthrough effectively overcomes the productivity limitations of tr...Read more -

Kaihua Home Appliance Molds: Powering Smarter Manufacturing with Premium Quality and Innovative Solutions

Kaihua has emerged as a trusted partner for leading home appliance brands through its deep industry expertise and continuous innovation in the competitive appliance mold market. Specializing in the R&D and manufacturing of precision molds for refrigerators, air conditioners, televisions, wash...Read more -

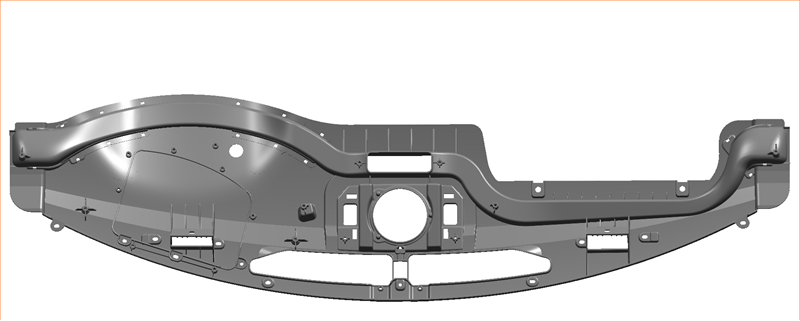

Kaihua Sets New Trends in Automotive Bumper Mold Selection with Free Spraying & High-Precision Manufacturing

Amidst the automotive industry’s shift toward intelligent and green manufacturing, technological innovation in exterior molds has emerged as a critical factor in enhancing vehicle competitiveness. As China’s leading automotive mold supplier, Kaihua Mold leverages its extensive experti...Read more -

KaiHua | Innovations in Injection Mold Design and Manufacturing Boost Efficiency for Clients

In an ongoing effort to meet the evolving needs of clientele, Kaihua company has been at the forefront of advancements in injection mold design and manufacturing. Drawing from recent research and comprehensive data collected, we are pleased to announce significant enhancements in Kaihua processes...Read more -

KaiHua | Kaihua Physical Foam Tray: Leading the Green and Lightweight Reform of the Tray Industry

The 19th China Tray International Conference and 2024 Global Tray Entrepreneurs Annual Meeting will be held in Ningbo from November 27-29, 2024. The conference aims to explore the application of intelligent and green technologies in the tray industry and tray recycling, and share advanced technol...Read more -

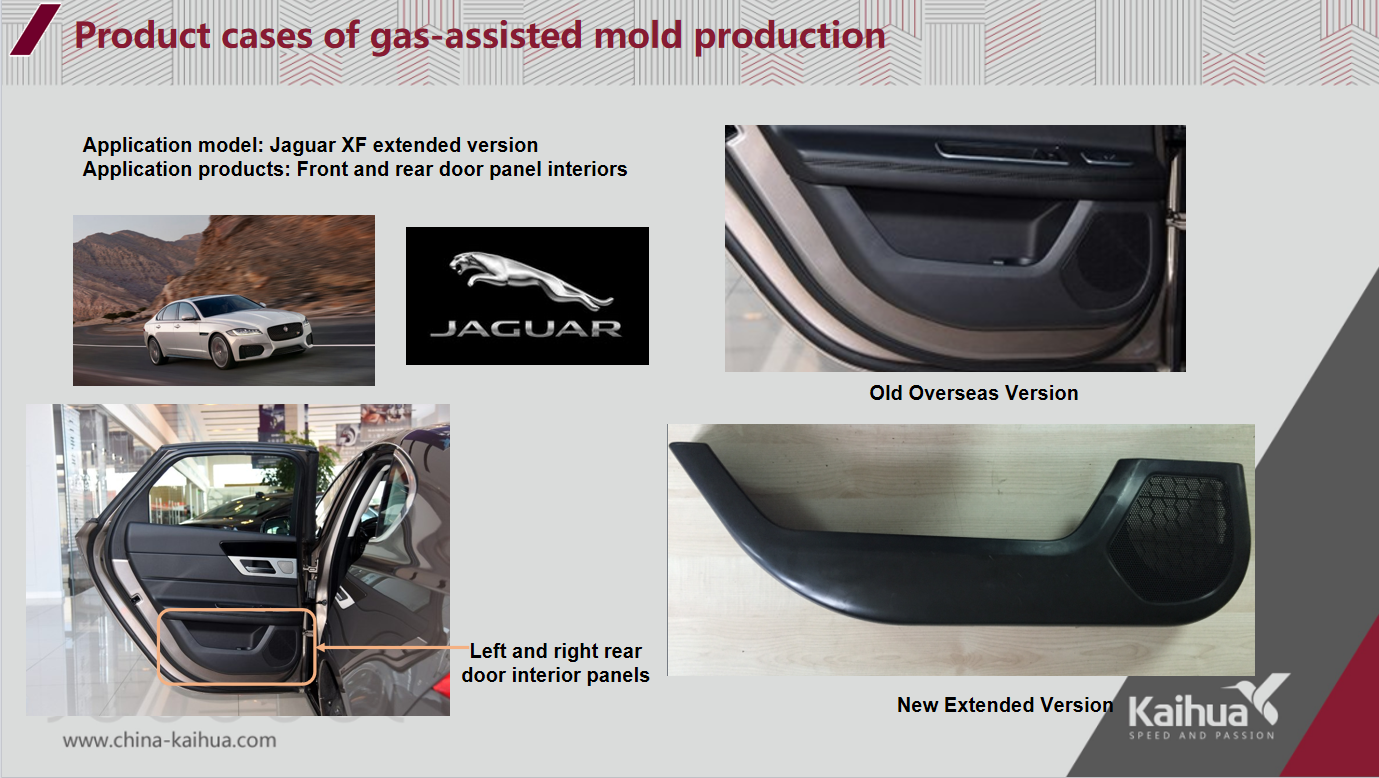

Gas-assisted molding technology: the innovative force leading theautomotive product manufacturing revolution

I. Introduction The rapid development of science and technology has made plastic products increasingly widely used in many fields. In the automotive industry, plastic products play a significant role in reducing vehicle weight and improving fuel efficiency. As an innovative plastic processing met...Read more -

Precautions for the use and maintenance of plastic pallets

As an indispensable part of the warehousing and logistics industry, plastic pallets play a decisive role.If the plastic pallet is used in accordance with the correct use specifications, not only give full exert to its own function, but also extend its service life and re...Read more -

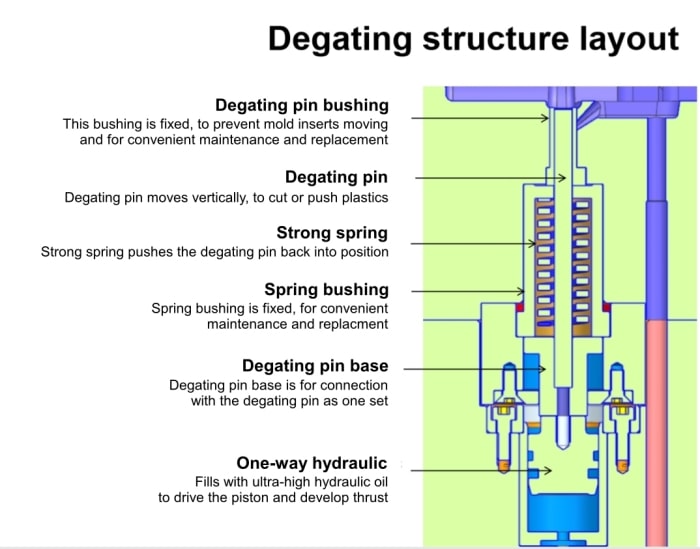

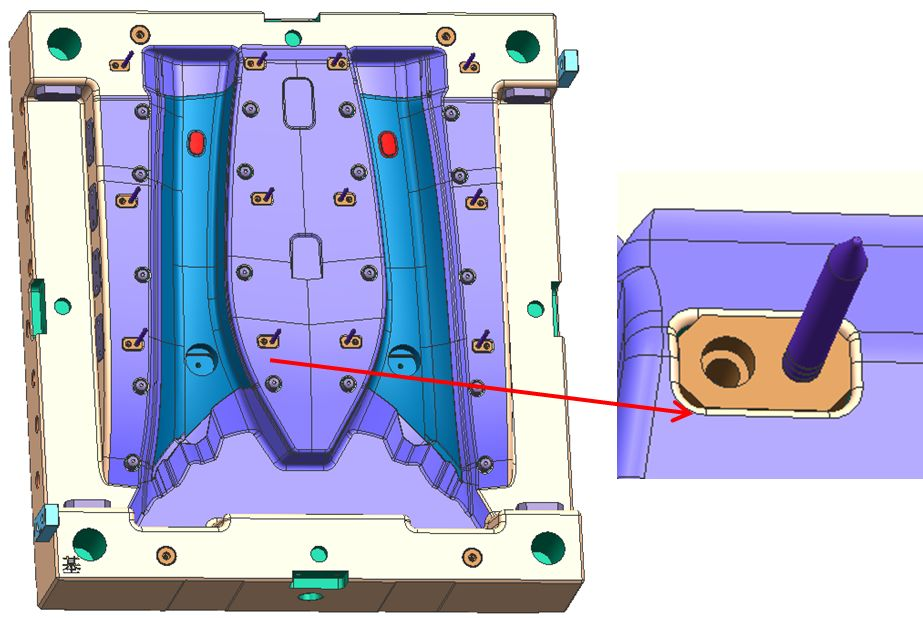

Kaihua Innovative Technology(07): In-mold Degate

In-mold degate is an automatic separation technology of the material gate of the plastic part and the product. A typical in-mold degate system consists of the following parts: micro ultra-high pressure oil cylinder, high-speed and high-pressure cutter, ultra-high pressure sequence control system ...Read more -

Kaihua Innovative Technology(06): Low Pressure Injection Molding

1.What is low pressure injection molding The low-pressure injection molding process is a packaging process that uses a very low injection pressure (0.15-4MPa) to inject the hot-melt material into the mold and quickly solidifies it. Temperature, impact resistance, vibration reduction, moisture-pr...Read more -

Kaihua Innovative Technology(05): Stack Mould

Different from conventional molds, the cavity of the stack mould is distributed on two or more layers, which is equivalent to stacking and combining multiple molds together. The most common two-layer die stack is usually installed by two single-layer dies back-to-back, and the parting surface is ...Read more -

Steel to Plastc Promotes Automotive Lightweight

Steel to plastic mainly uses engineering plastics such as PP, PC and ABS to replace traditional steel as aotomotive’s body parts, reducing the weight of the whole vehicle to 1/4-1/8 of the original weight, and realizing the lightweight of the vehicle, meanwhile reducing vehicle fuel consumption. ...Read more