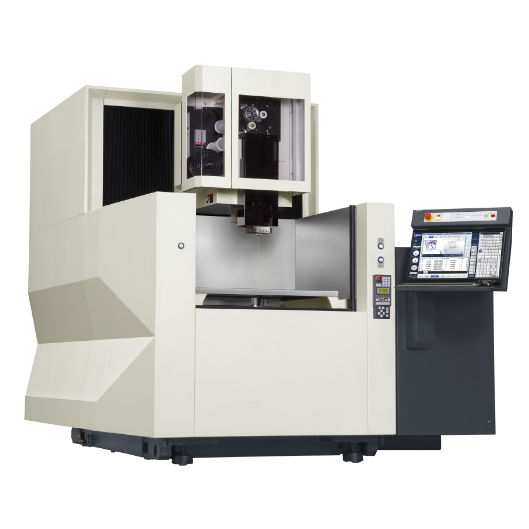

Wire-Cutting Machine

1.Product Introduction

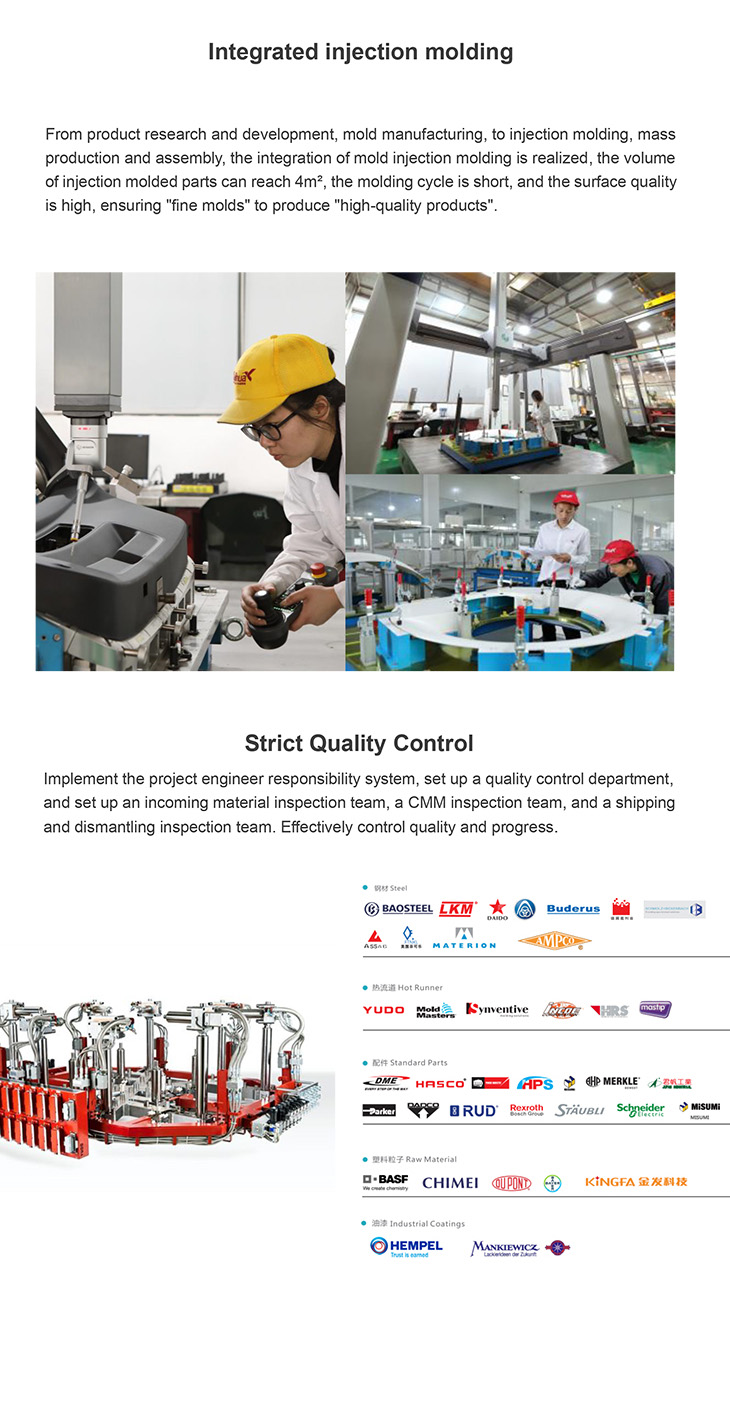

In today's fast-paced world, the manufacturing industry is constantly looking for ways to streamline their processes and reduce maintenance requirements. One of the recent developments that have had a huge impact on this sector is the Wire-Cutting Machine. These machines use a thin wire as an electrode to cut through materials with precision and accuracy. In this blog, we will discuss the benefits and features of wire-cutting machines, with a focus on the Kaihua Mold Wire-Cutting Machine.

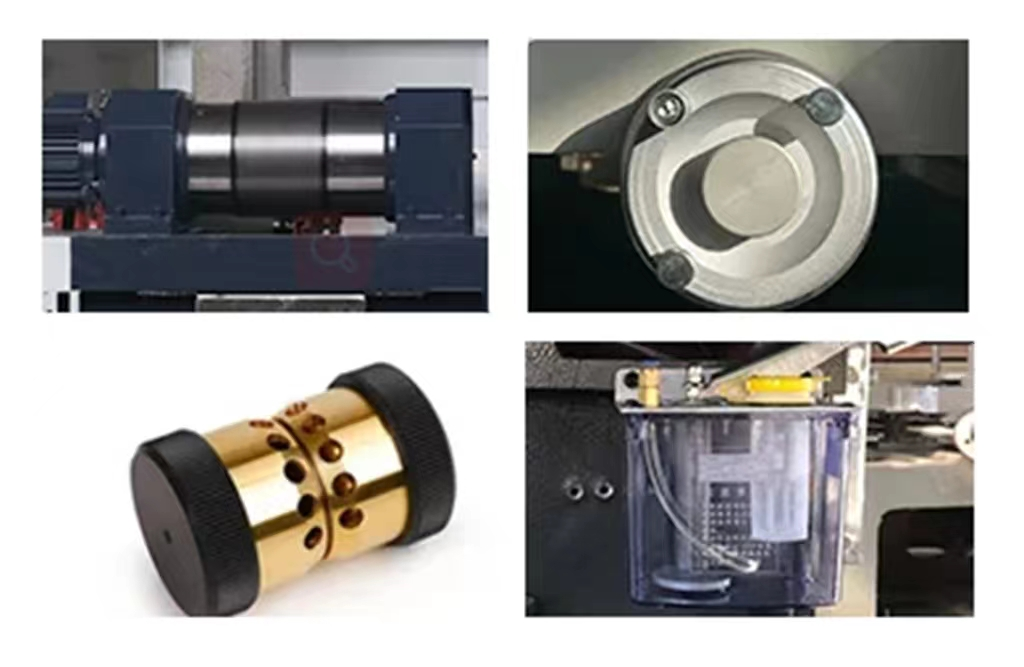

Significantly Reduced Maintenance Requirements

One of the primary advantages of using a wire-cutting machine is that it significantly reduces maintenance requirements. The Kaihua Mold Wire-Cutting Machine uses a main dielectric filter installed in a non-submerged cabinet, which helps to drain the water from the used filter before replacement. This feature is useful in reducing the weight of the used filter while at the same time preventing the traditional dirty, slippery hazards usually associated with changing filters.

Integrated Filter Air Purification Function

The Kaihua Mold Wire-Cutting Machine is equipped with an integrated filter air purification function. This function ensures that the used filter is purified before replacing it. As a result, there is no need to clean or replace dirty filters, which saves time and cuts operational costs. The air purification function also enhances the overall efficiency of the machine by ensuring that the filters are clean at all times.

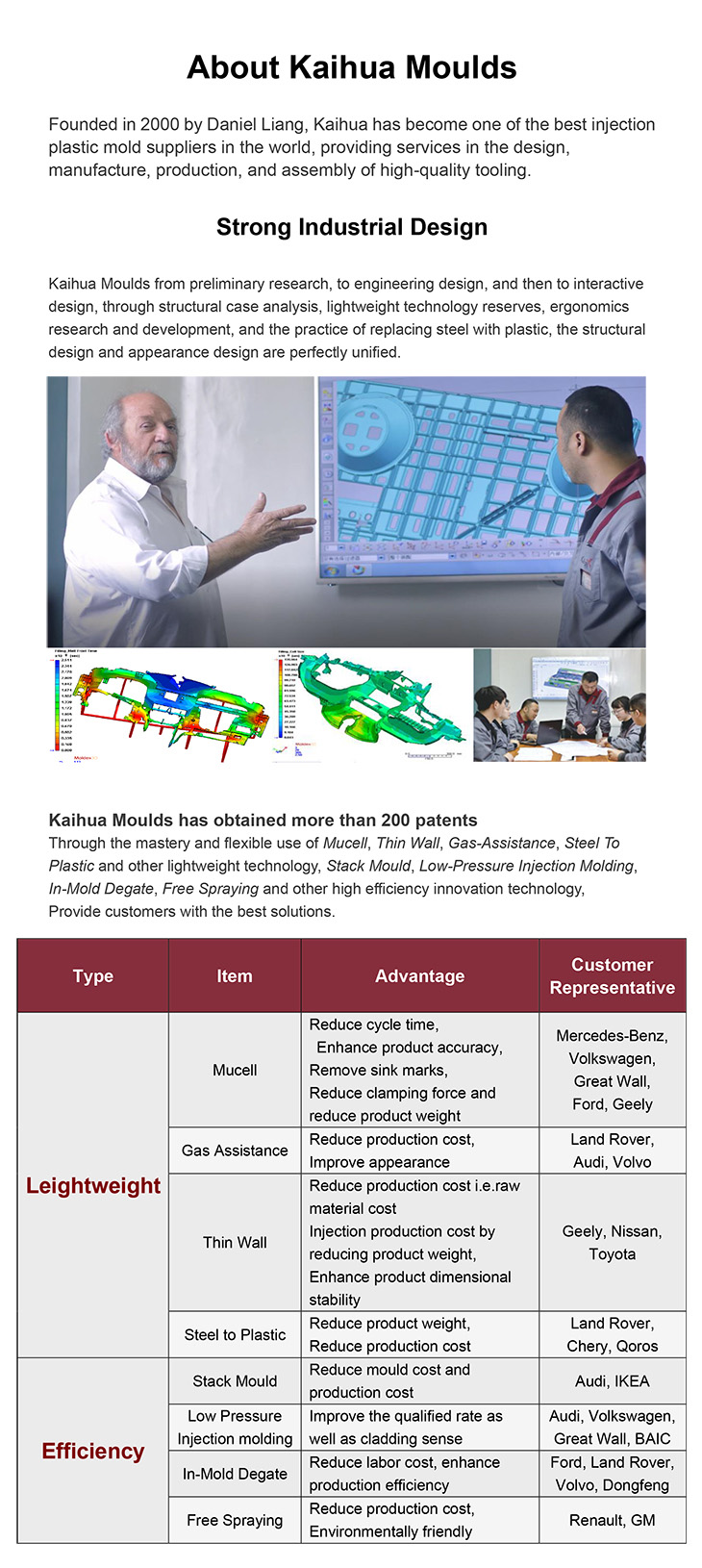

Versatility in Materials

Another benefit of the wire-cutting machine is its versatility in cutting materials. Whether it is plastic, metal, or composite materials, wire-cutting machines can cut through them with ease and precision. This versatility makes it an excellent choice for manufacturers who deal with a variety of materials and products.

Accuracy and Precision

Wire-cutting machines are known for their accuracy and precision in cutting materials. The Kaihua Mold Wire-Cutting Machine is no exception. It can cut to tolerances as low as +/- 0.005mm, making it an excellent choice for micro-machining and other precision jobs. The ability to achieve such precision makes it a valuable tool for manufacturers.

In conclusion, wire-cutting machines have revolutionized the manufacturing industry by reducing maintenance requirements, enhancing efficiency, and improving accuracy and precision. With the Kaihua Mold Wire-Cutting Machine, manufacturers have an excellent option for their machining needs. It is an outstanding tool that provides quality, precision, and efficiency in cutting materials.

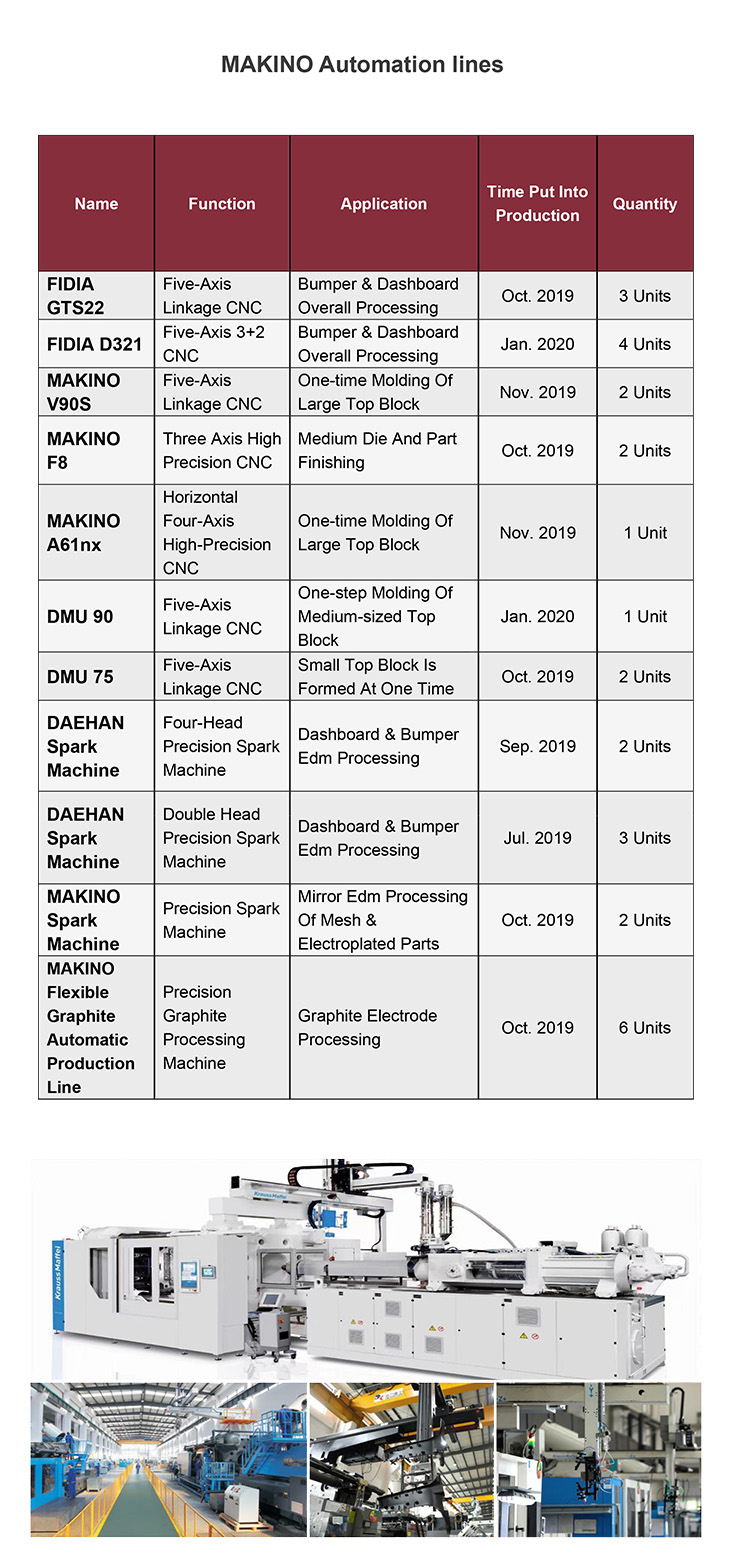

2.Product Parameter (Specification)

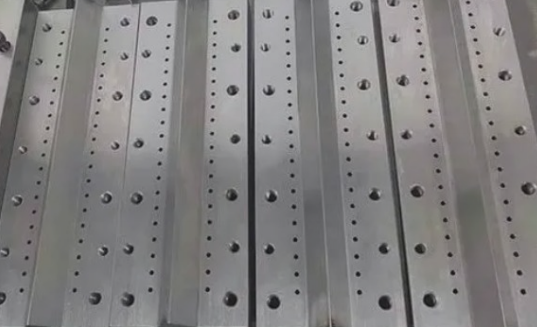

| X Travel | 650mm |

| Y Travel | 450mm |

| Z Travel | 420mm |

| Max Work Dimension | 1000 x 800 x 420 |

| Max Work Mass | 1500kg |

| Tank Size | 1070 x 880mm |

| Usable Wire Size | 0.100mm, 0.150mm, 0.200mm, 0.250mm, 0.300mm |

3.Product Feature and Application